Work assembling device and assembling method

A technology for assembling devices and workpieces, applied in positioning devices, metal processing machinery parts, assembling machines, etc., can solve the problems of limited space and work efficiency, and achieve the effect of easy operation and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0063] Embodiments of the present invention will be described with reference to the drawings.

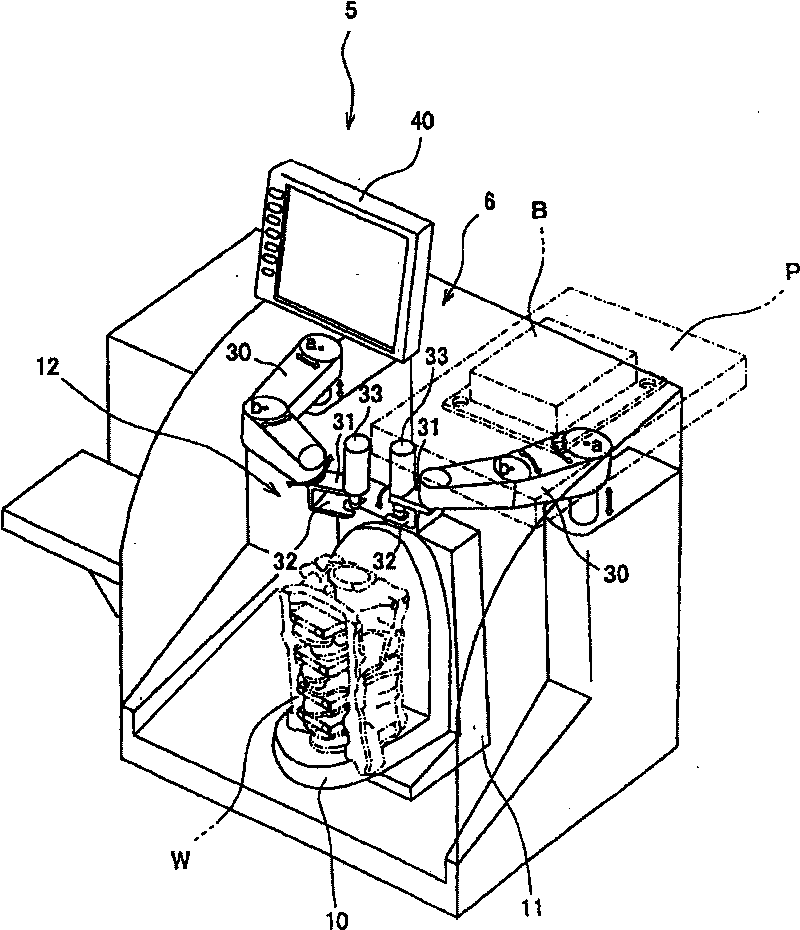

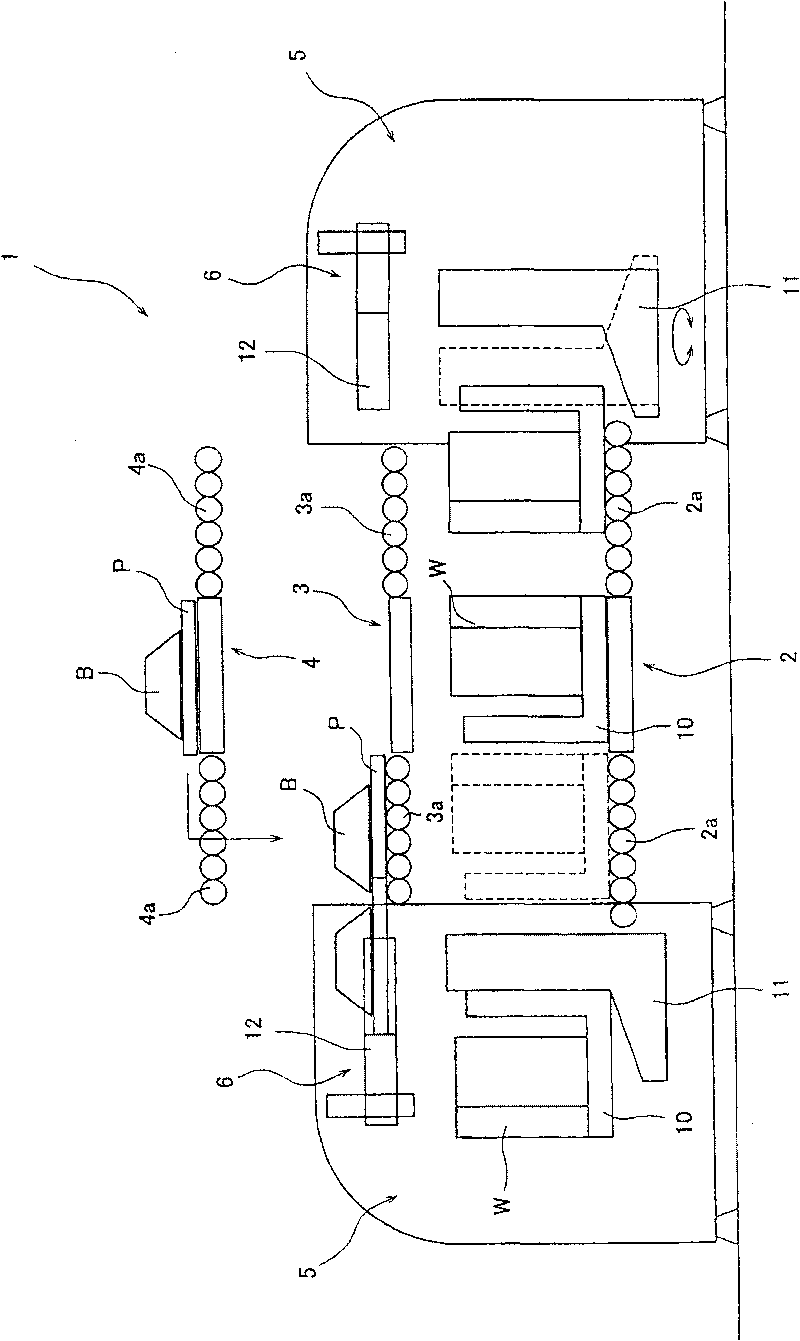

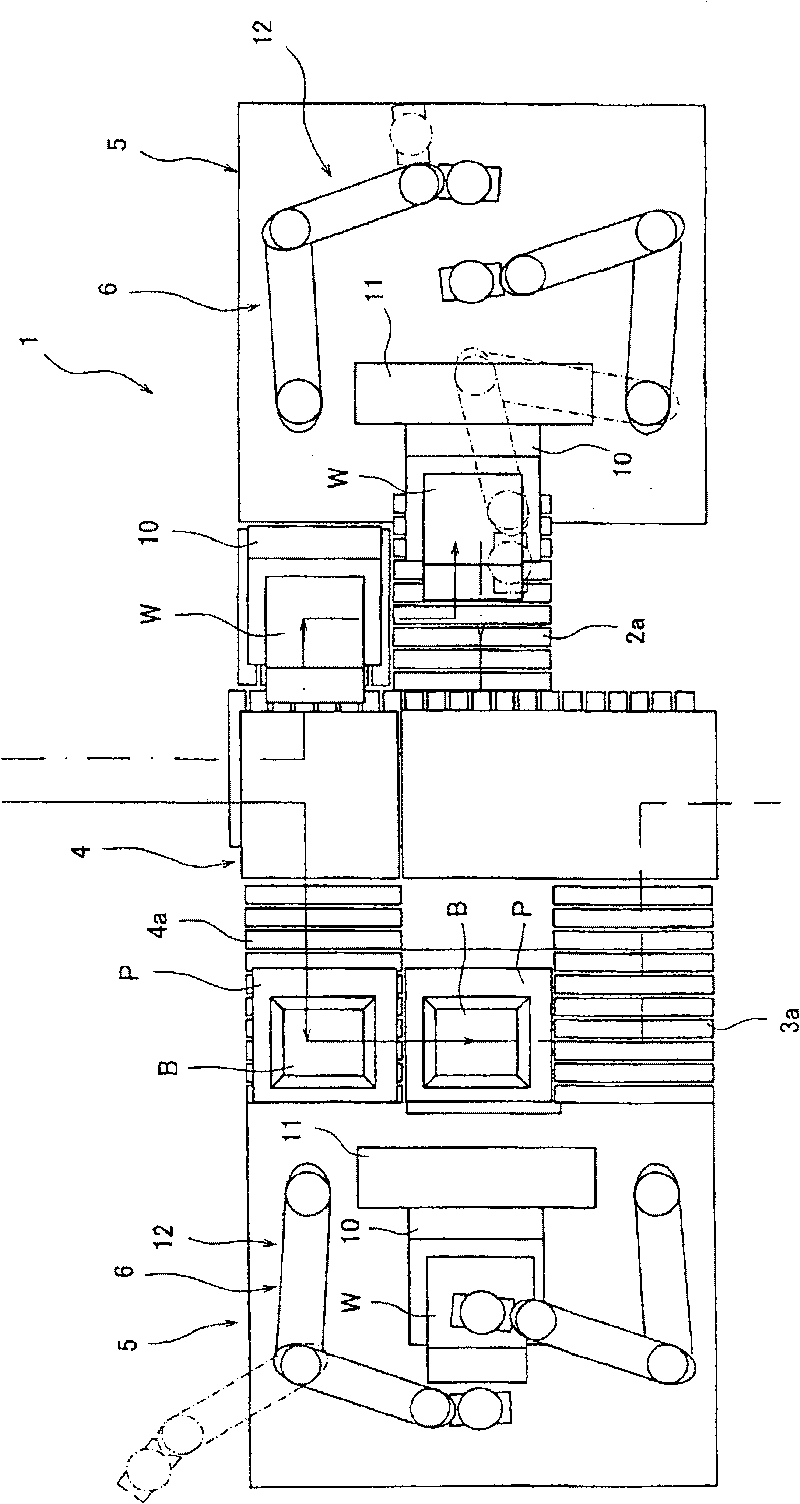

[0064] here, figure 1 It is a perspective view showing the appearance of this workpiece mounting device, figure 2 It is the front view of the whole workpiece assembly system, image 3 is the plan view of the same workpiece assembly system, Figure 4 is an explanatory diagram of the workpiece holding jig and column, Figure 5 It is an explanatory diagram of the internal structure of the workpiece holding jig, Figure 6 It is an explanatory diagram showing an example of changing the posture of the workpiece by the workpiece holding jig, Figure 7 It is an explanatory diagram of the state of holding parts with the parts holding device, Figure 8 It is an explanatory diagram showing the advantage of vertical assembly.

[0065] The workpiece assembly device of the present invention can efficiently assemble a workpiece having component assembly surfaces on multiple surfaces, and ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com