An apparatus for discharging a residual part of a resin tube in an automatic bookbinding machine

A residual resin, automatic binding technology, applied in the book binding, binding, printing and other directions, can solve the problem of the length of the resin tube cannot be confirmed from the outside, difficult to use the resin tube effectively, injury and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

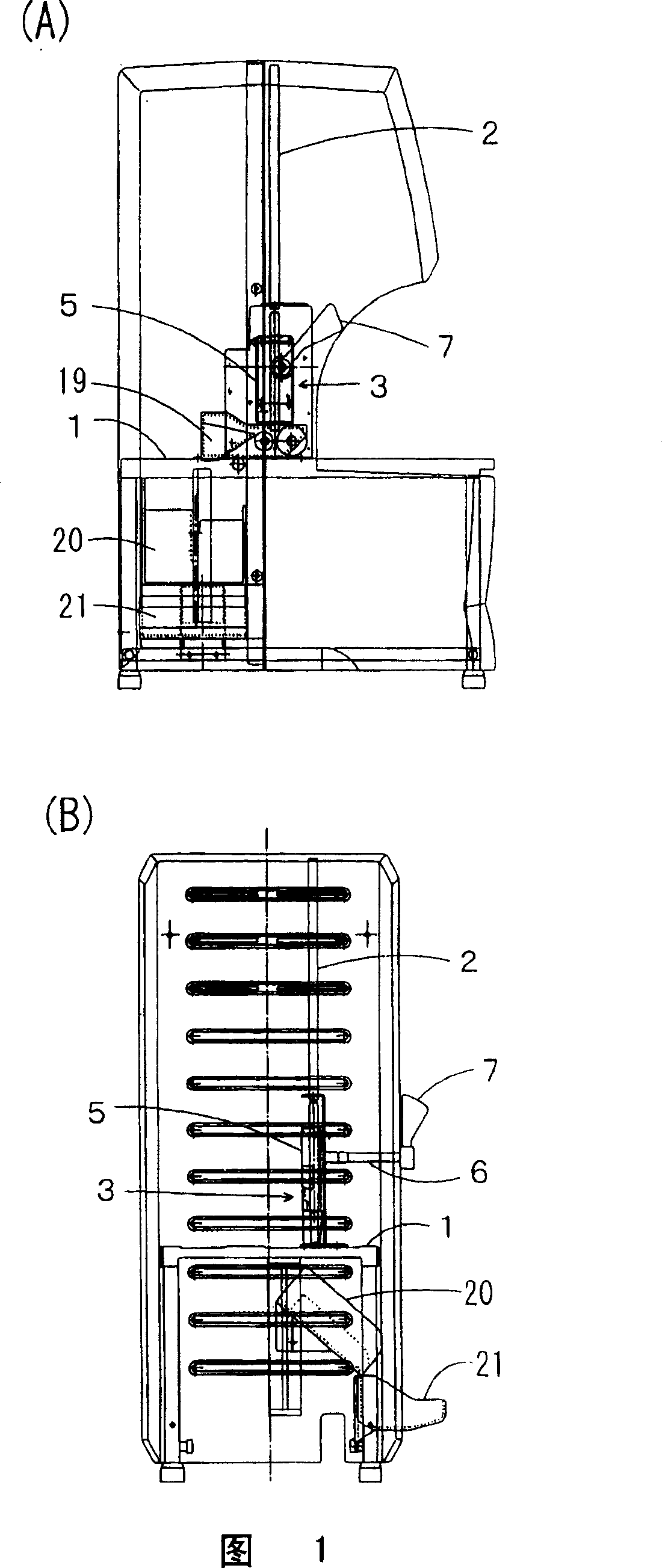

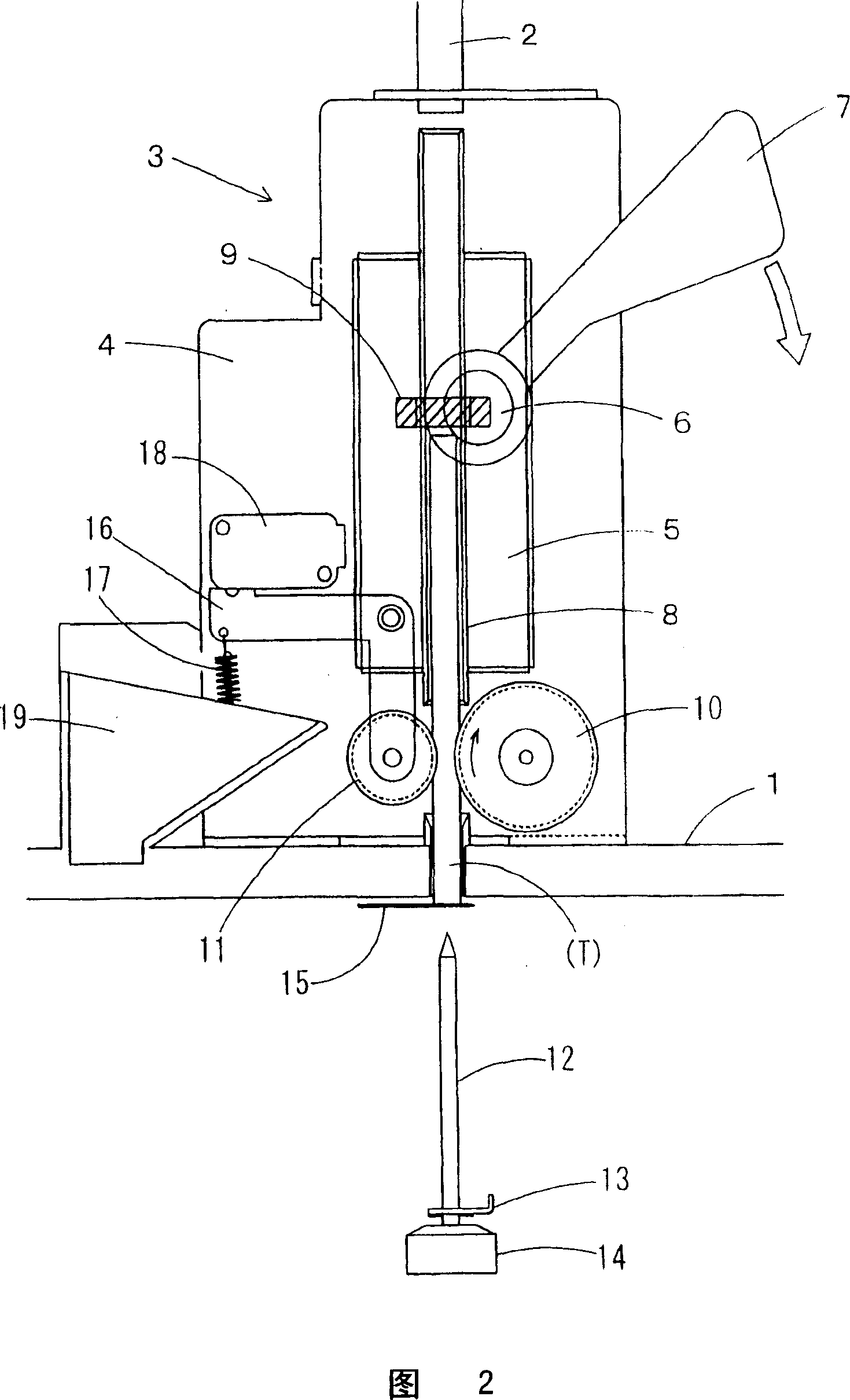

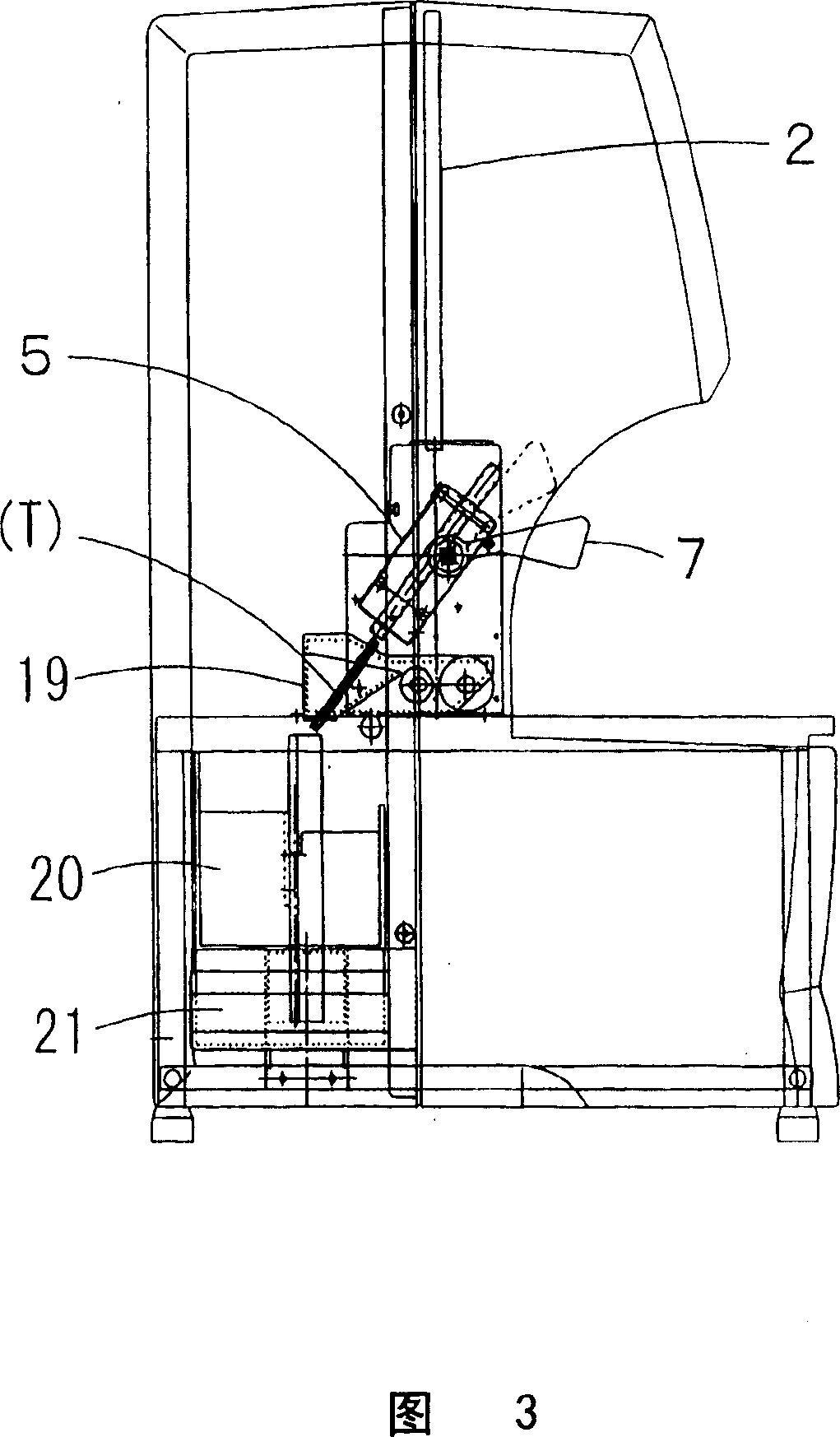

[0039] Next, preferred embodiments of the discharge device for residual resin tubes according to the present invention will be described with reference to the drawings. Fig. 1 (A) is a side view of the automatic binding machine, and Fig. 1 (B) is a rear view, both of which show the positional relationship of the discharge device of the present invention in the whole. In addition, FIG. 2 is a schematic configuration diagram of a discharge device for residual resin tubes.

[0040] In Fig. 1 and Fig. 2, 1 is the base of automatic binding machine, and the device that is used for piercing the binding hole on the document, the device that supplies the resin tube of each expected length, and the device that forms binding bar are respectively installed (all not shown in the figure). ). 2 is a resin tube conduit installed vertically downward from the top surface of the main body of the automatic binding machine, and actually supplies long resin tubes to the above-mentioned device for ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap