Photographic printing machine having translational cam mechanism for driving paper-pressing drum vertically lifting/lowering

A technology for translating cams and photocopiers, which is applied in the direction of printing and printing devices, and can solve the problems that other parts cannot be tolerated and exist in between.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

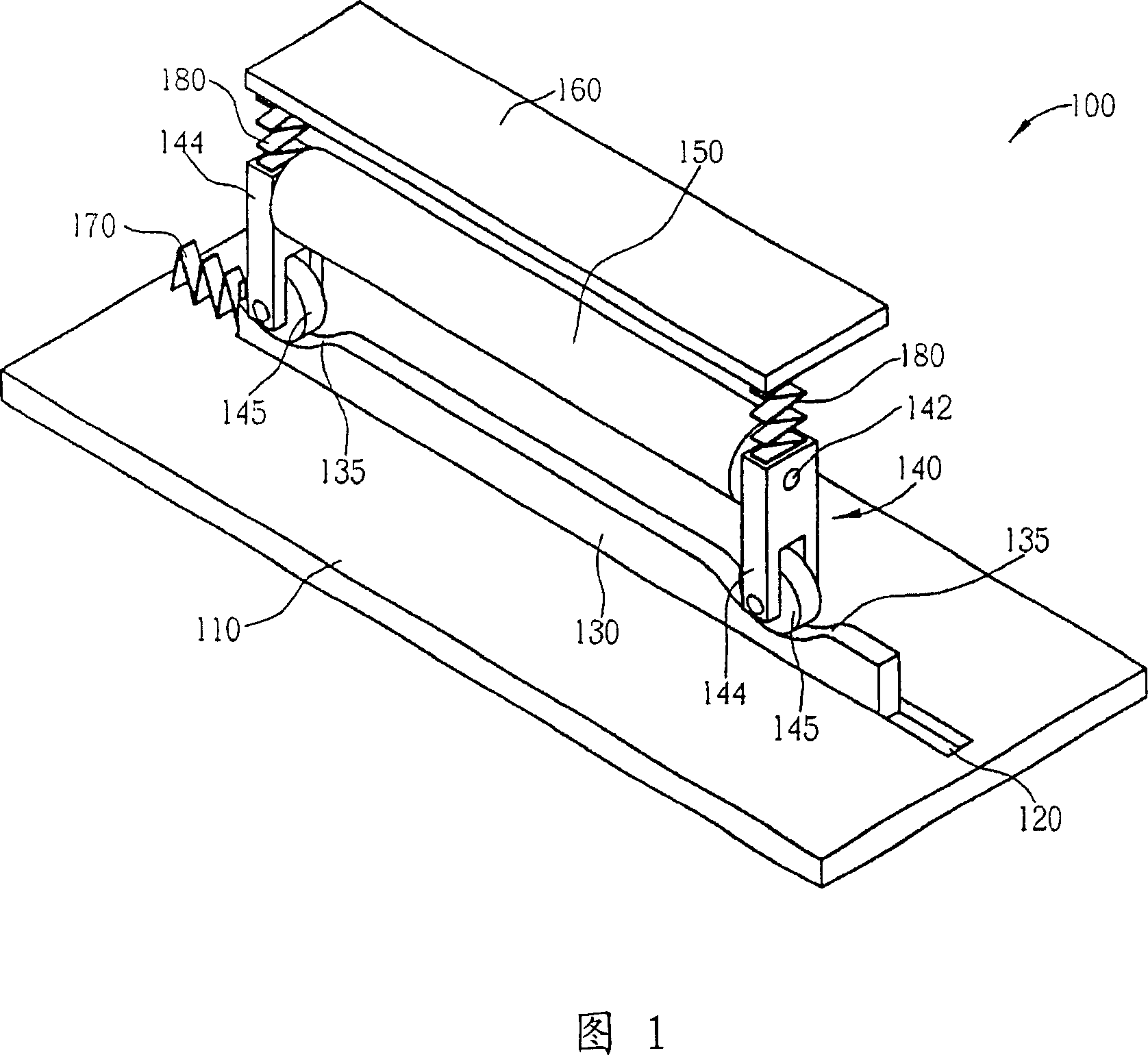

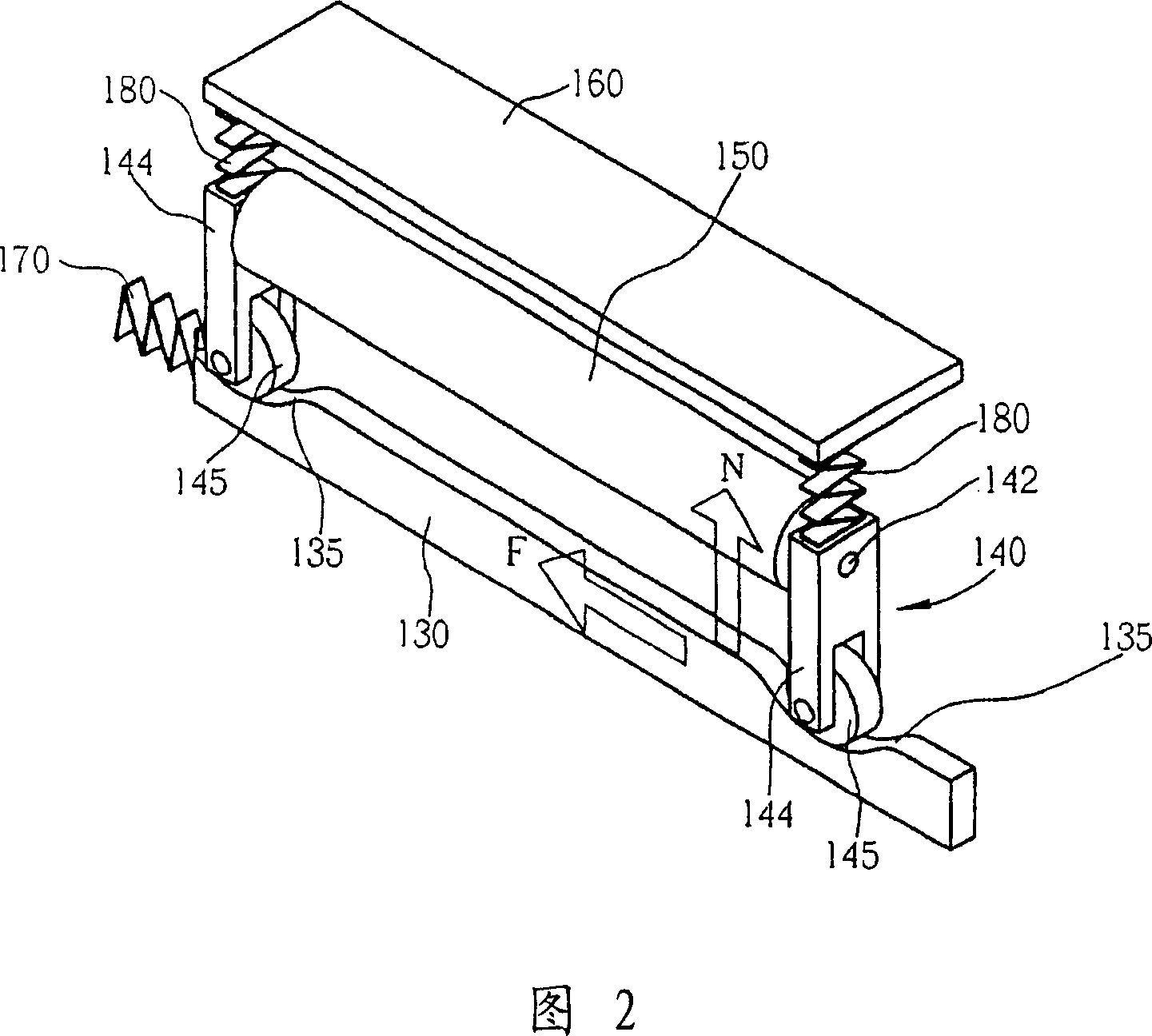

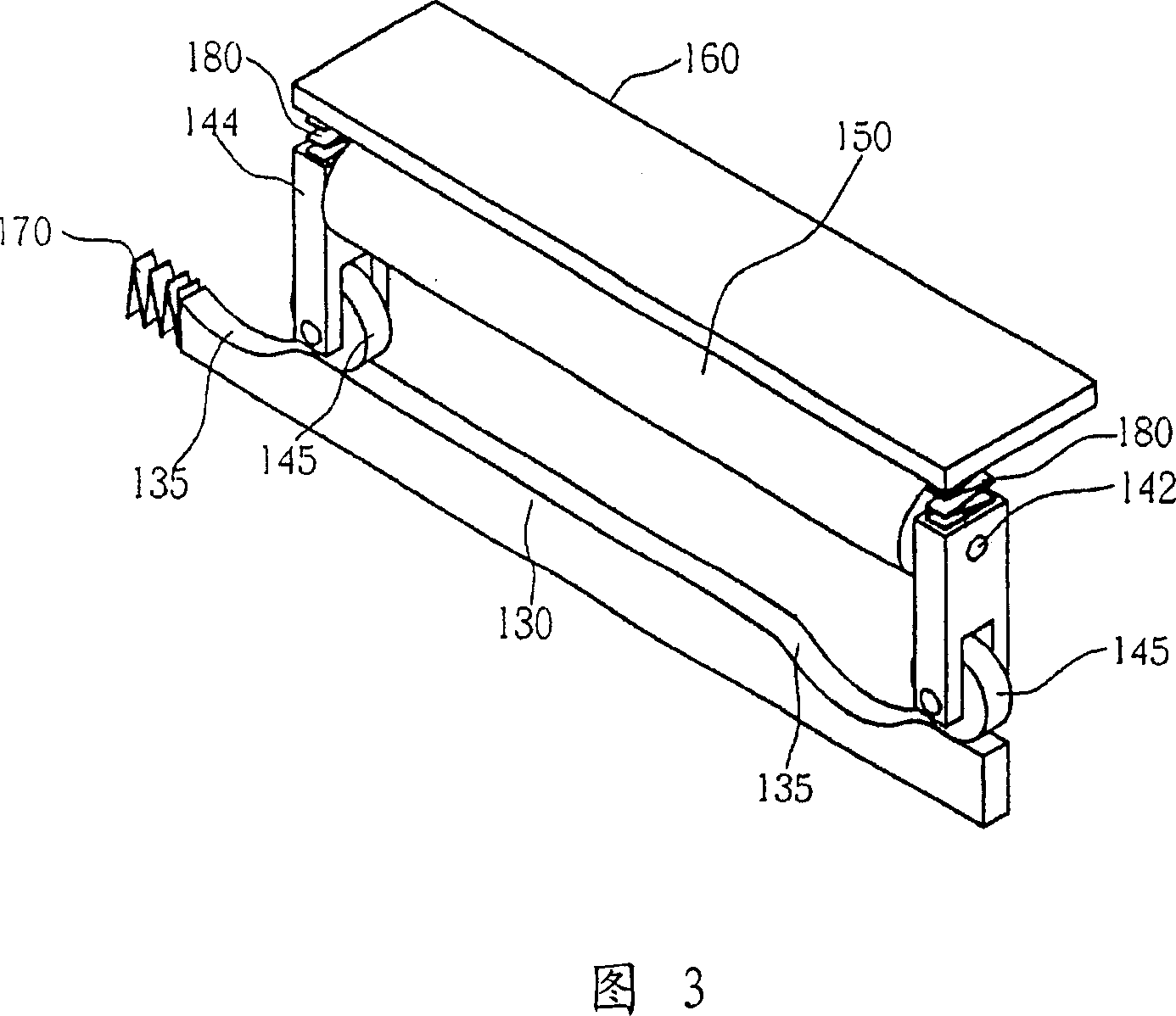

[0012] Refer to Figure 1. FIG. 1 is a schematic diagram of a photocopier 100 with a cam mechanism capable of driving a platen roller 150 to vertically lift and translate according to the present invention. Photocopier 100 includes a housing 110, on which is provided with a track 120, a translation cam 130, has a plurality of concave surfaces 135, a cylinder support group 140, a platen cylinder 150, a print head 160 and elastic device 170, 180. The roller bracket set 140 includes two pin brackets 144 , and each pin bracket 144 includes a shaft hole 142 and a roller 145 .

[0013] The translation cam 130 is installed on the track 120 in a manner that can move horizontally along the track 120 , and the roller support group 140 is placed on the translation cam 130 . Platen cylinder 150 is fixed on the cylinder bracket group 140 in a rotatable manner, wherein the shaft hole 142 of each pin bracket 144 of cylinder bracket group 140 is used to install the pressure cylinder 150, so ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com