Rotary saw

A technology of rotation direction and base parts, which is applied in the direction of sawing machine devices, metal sawing equipment, and knives of sawing machine devices. Ease of formation, effect of function improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Embodiments of the present invention will be described below with reference to the drawings.

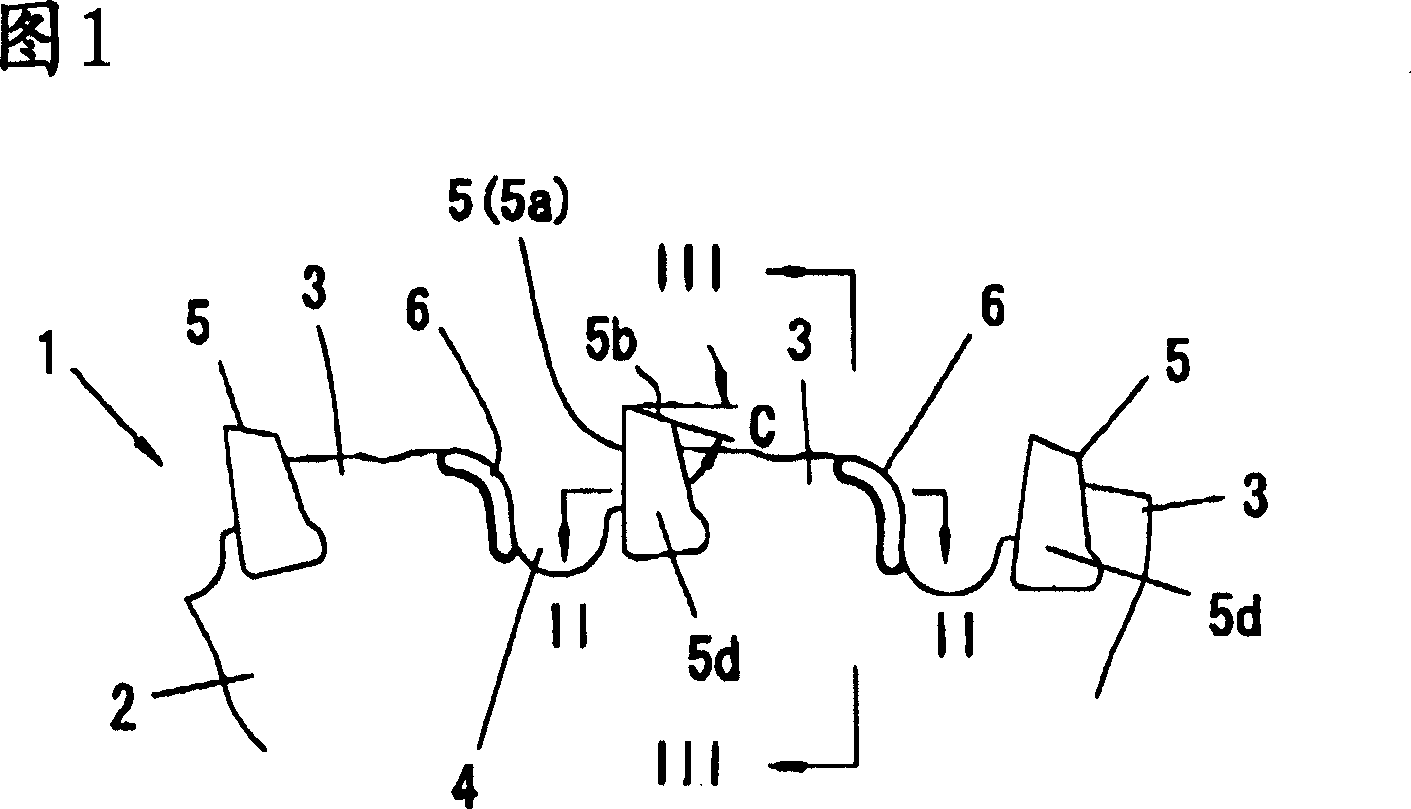

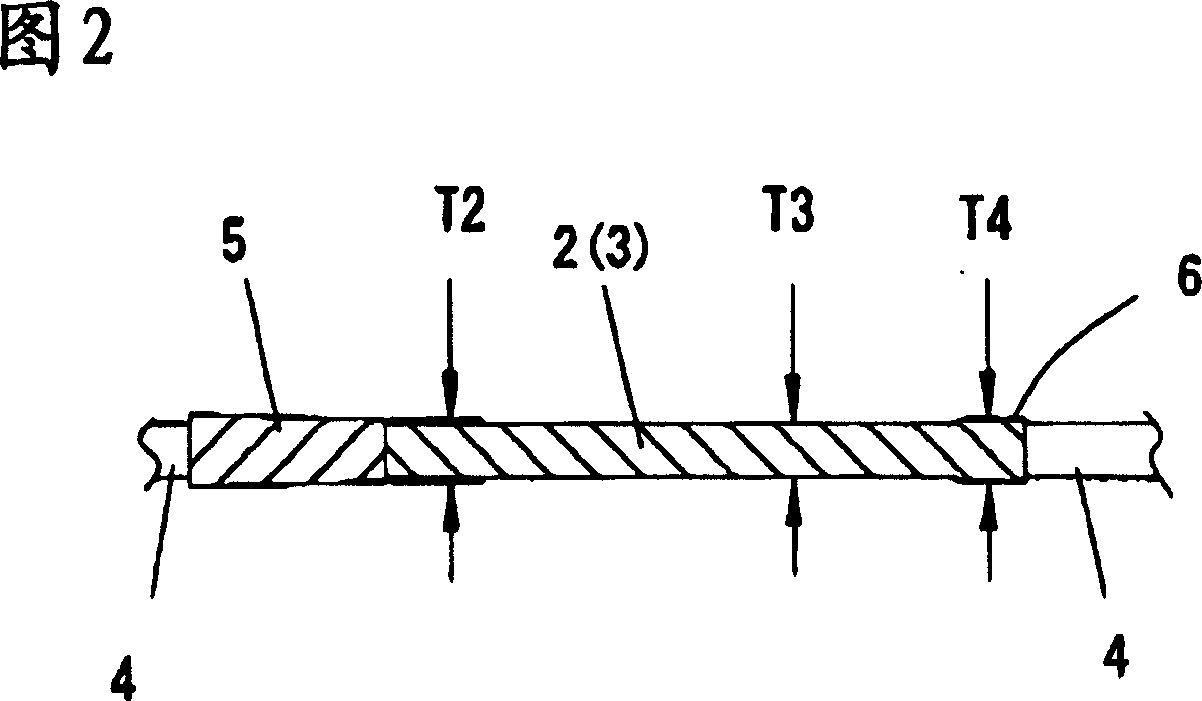

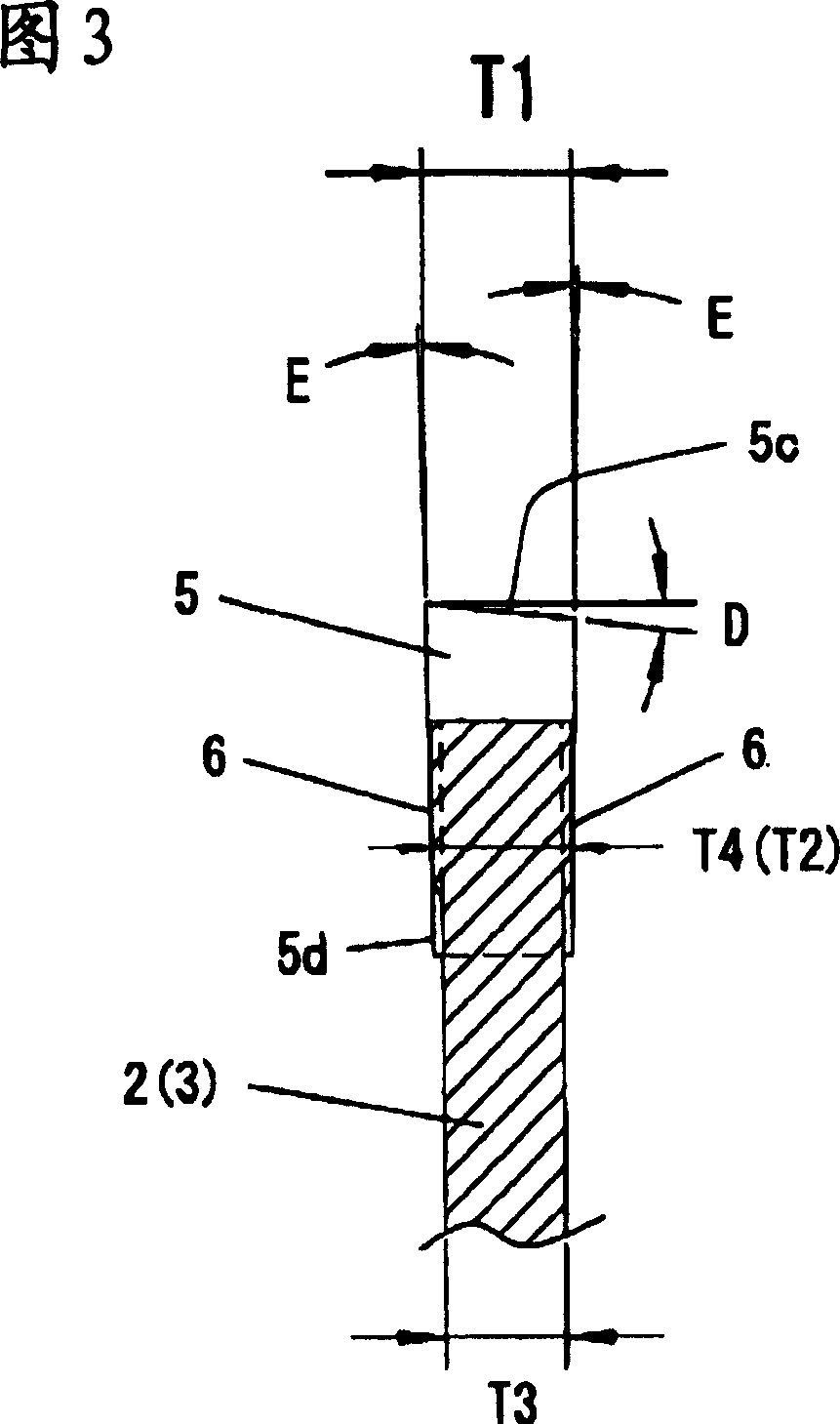

[0020] In the accompanying drawings, Fig. 1 is a partial side view of the first embodiment of the present invention; Fig. 2 is an enlarged side view of the II-II line of Fig. 1; Fig. 3 is an enlarged sectional view of the III-III line of Fig. 1; Fig. 4 is the partial side view of the 2nd embodiment of the present invention; Fig. 5 is the partial side view of the 3rd embodiment of the present invention; Fig. 6 is the partial side view of the 4th embodiment of the present invention; Fig. 7 is Fig. 6 The enlarged cross-sectional view of the VII-VII line;

[0021] Among Fig. 1~3, 1 is the rotary saw that cuts steel; 2 is the base part of rotary saw. The base member 2 is formed of alloy knife steel (JIS standard: SK5, SK6), and in this embodiment, it is formed into a disc shape with an outer diameter of about 185 mm and a reference thickness T3 of about 1.6 mm, and at the same tim...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com