Rotary casing roll

A technology of rotating shells and drums, used in manufacturing tools, calenders, papermaking, etc., can solve the problems of component retention, pad instability, accidental contact of shells, etc., and achieve the effect of improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

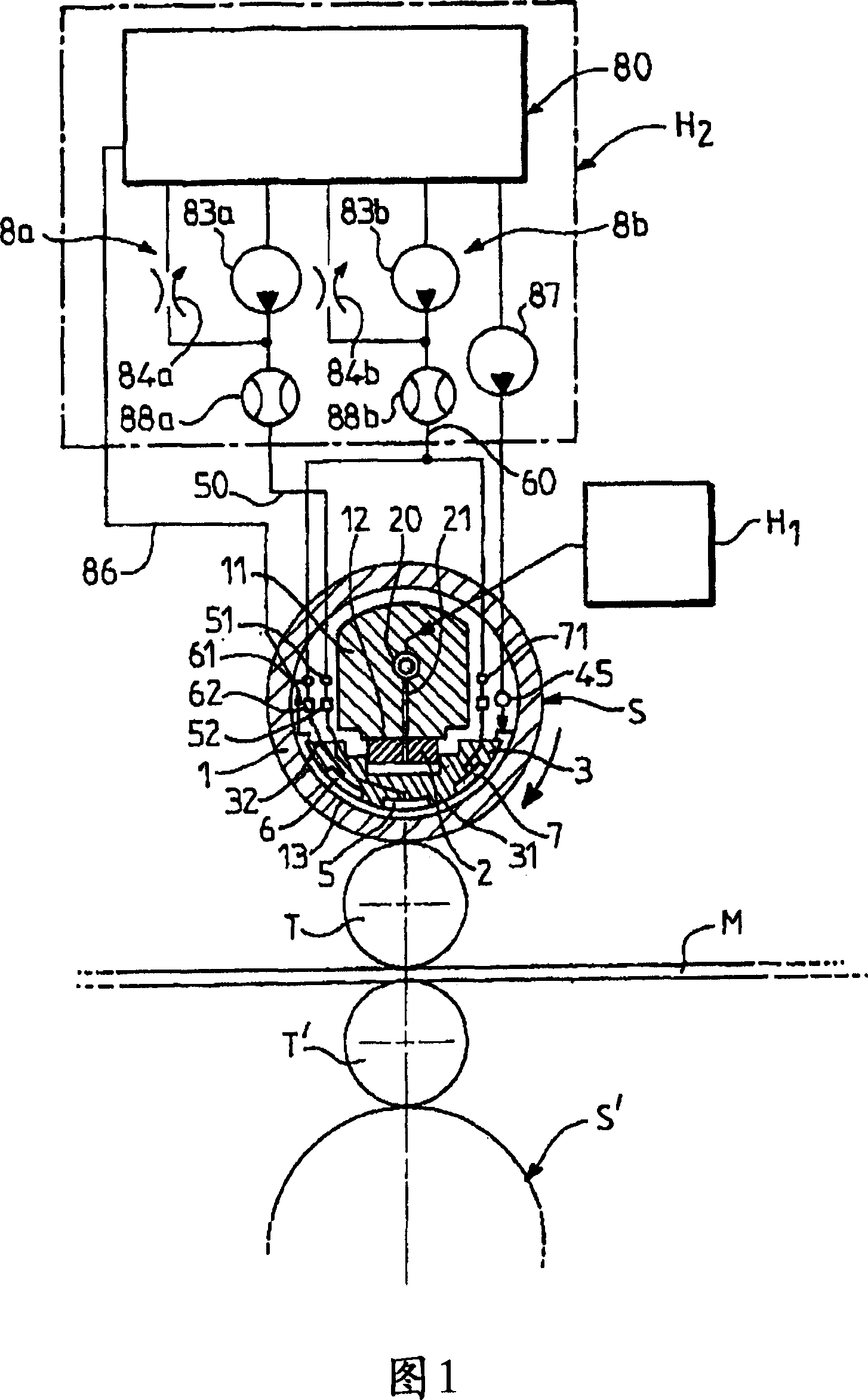

[0040] [40] As shown in Fig. 1 in transverse section as an example, a four-high rolling mill includes two work rolls T, T', between which a rolled product M passes, said work rolls T, T' being respectively on opposite sides of the product Supported on two support rollers S, S' between which a fastening force is exerted along a support plane P passing substantially by the axis of the drum.

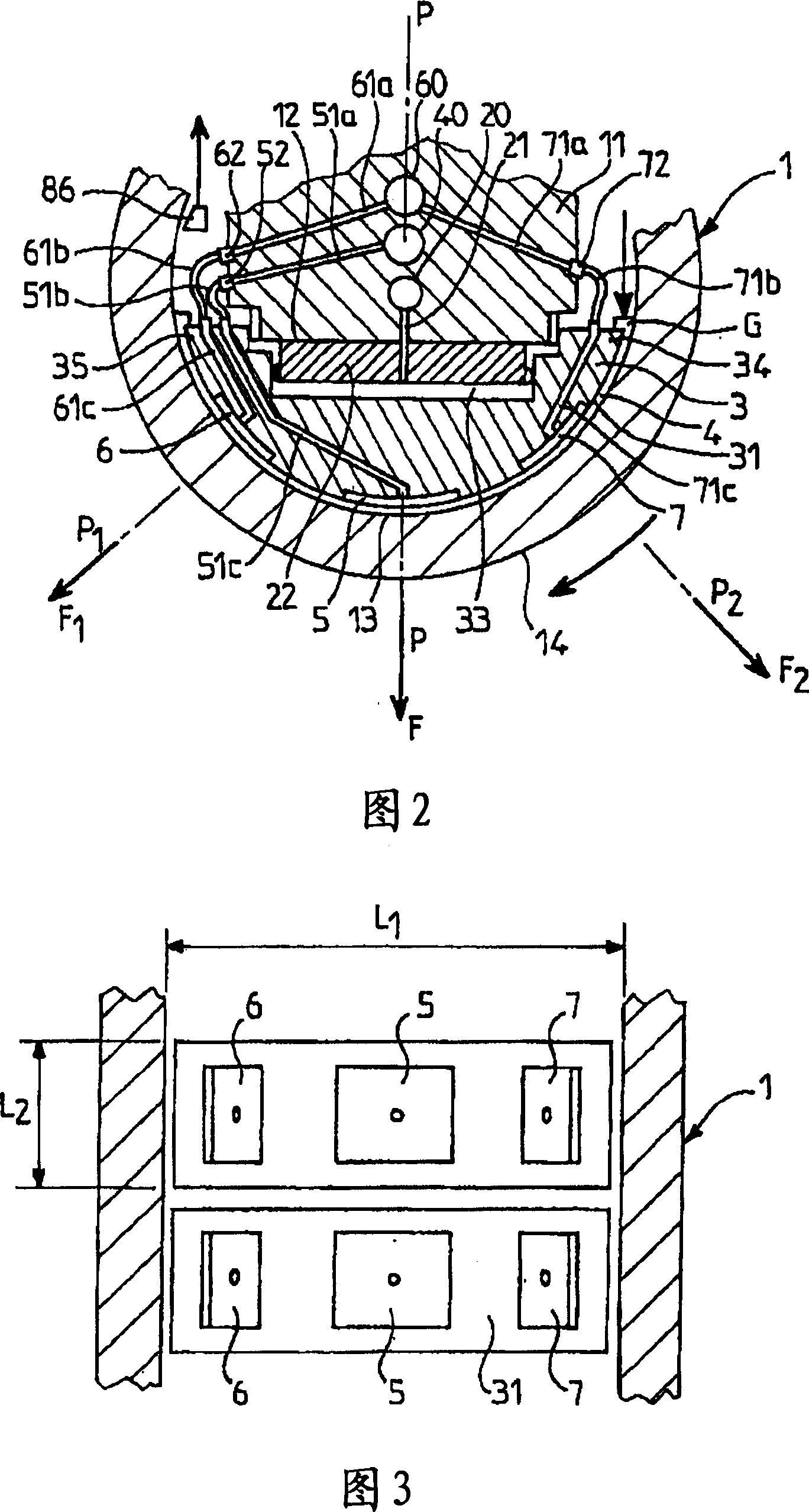

[0041] [41] At least one of the supporting rollers, for example the upper supporting roller S, consists of a tubular casing 1 which is rotatably mounted at its ends on a supporting beam 11 via abutments A, A' shown in FIG. 4 , the support beams 11 extend transversely to the rolling direction inside the tubular housing 1 , and the abutments A, A' define an axis of rotation x'x of the housing.

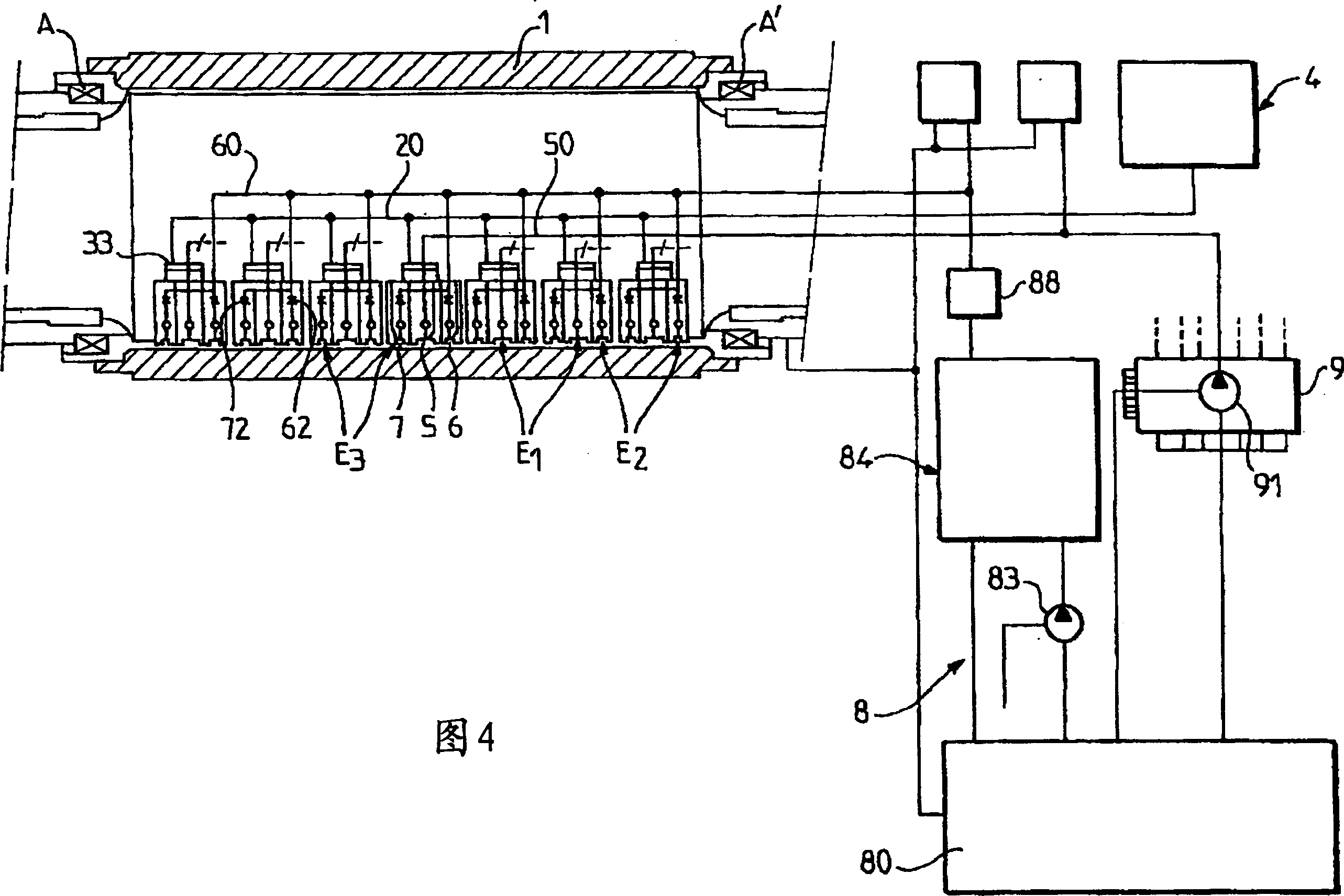

[0042] [42] As shown in Fig. 4, the tubular casing 1 is supported on the beam 11 by a plurality of retaining pads 3 distributed over its entire length and interposed between the between the cylindric...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com