Discharge circuit and duty ratio setting method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] A simultaneous discharge circuit and a simultaneous battery discharge method according to an embodiment of the present invention will be described with reference to the attached drawings.

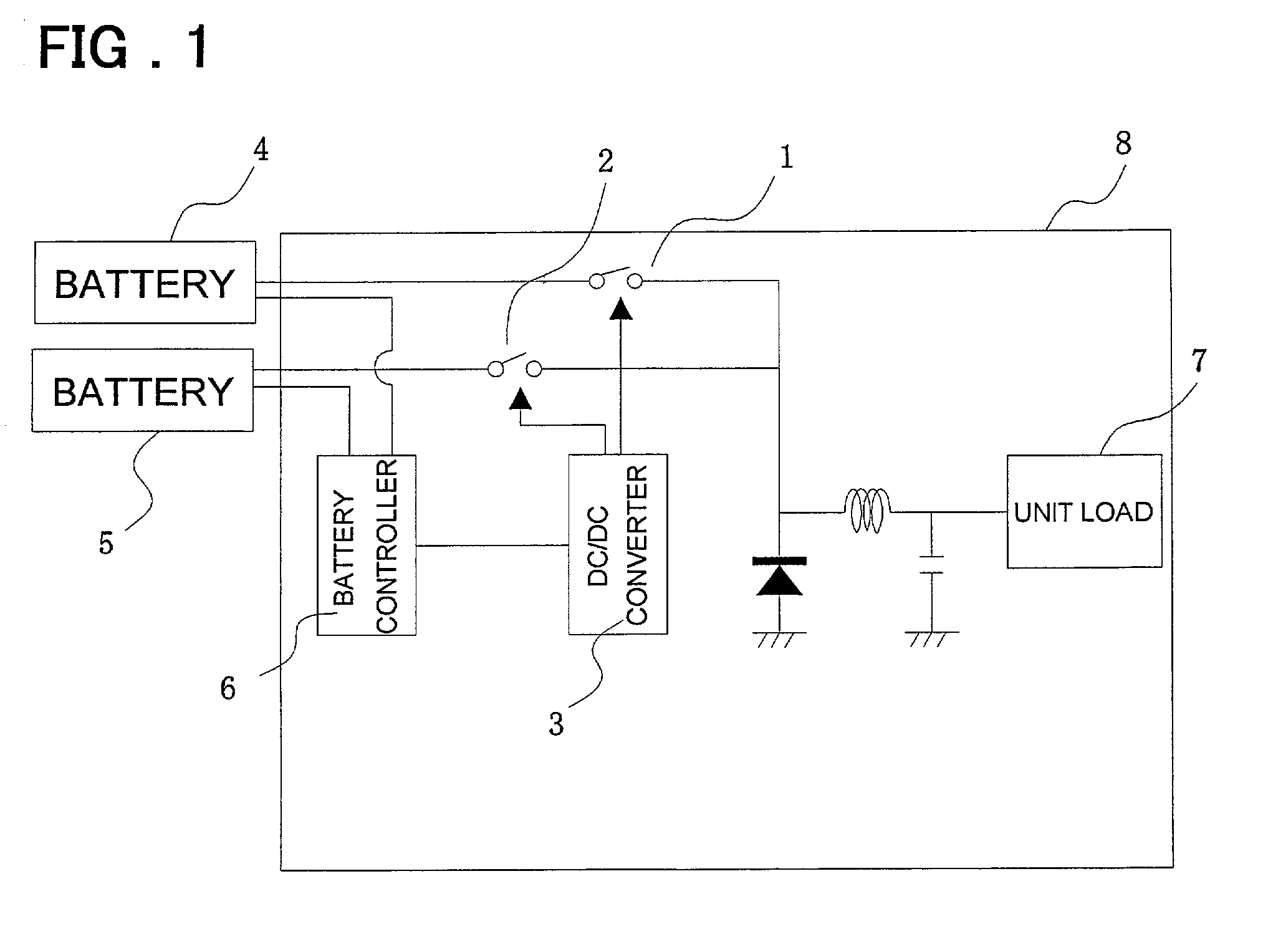

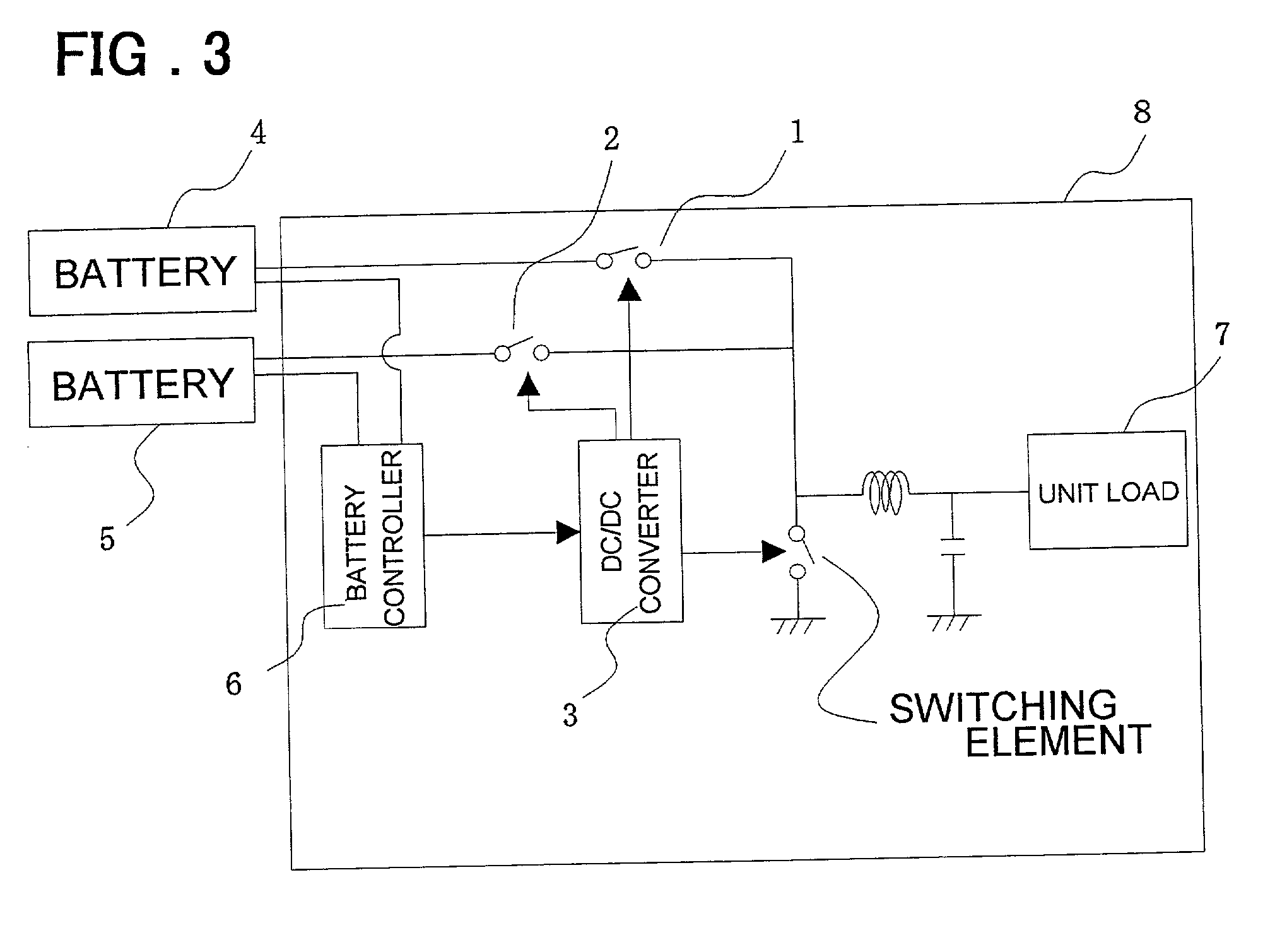

[0025] FIG. 1 is a diagram showing the configuration of a discharge circuit used in a first embodiment of the present invention.

[0026] The discharge circuit used in the fist embodiment of the present invention has a data processing apparatus 8 comprising a DC / DC converter 3 controlling a switching element 1 and a switching element 2 to convert the DC voltage, a battery controller 6 connected to the DC / DC converter 3 and to a battery 4 and a battery 5, and a unit load 7. The battery 4 and the battery 5 supply power to the data processing apparatus 8. The battery 4 is connected to the switching element 1 and the battery 5 to the switching element 2.

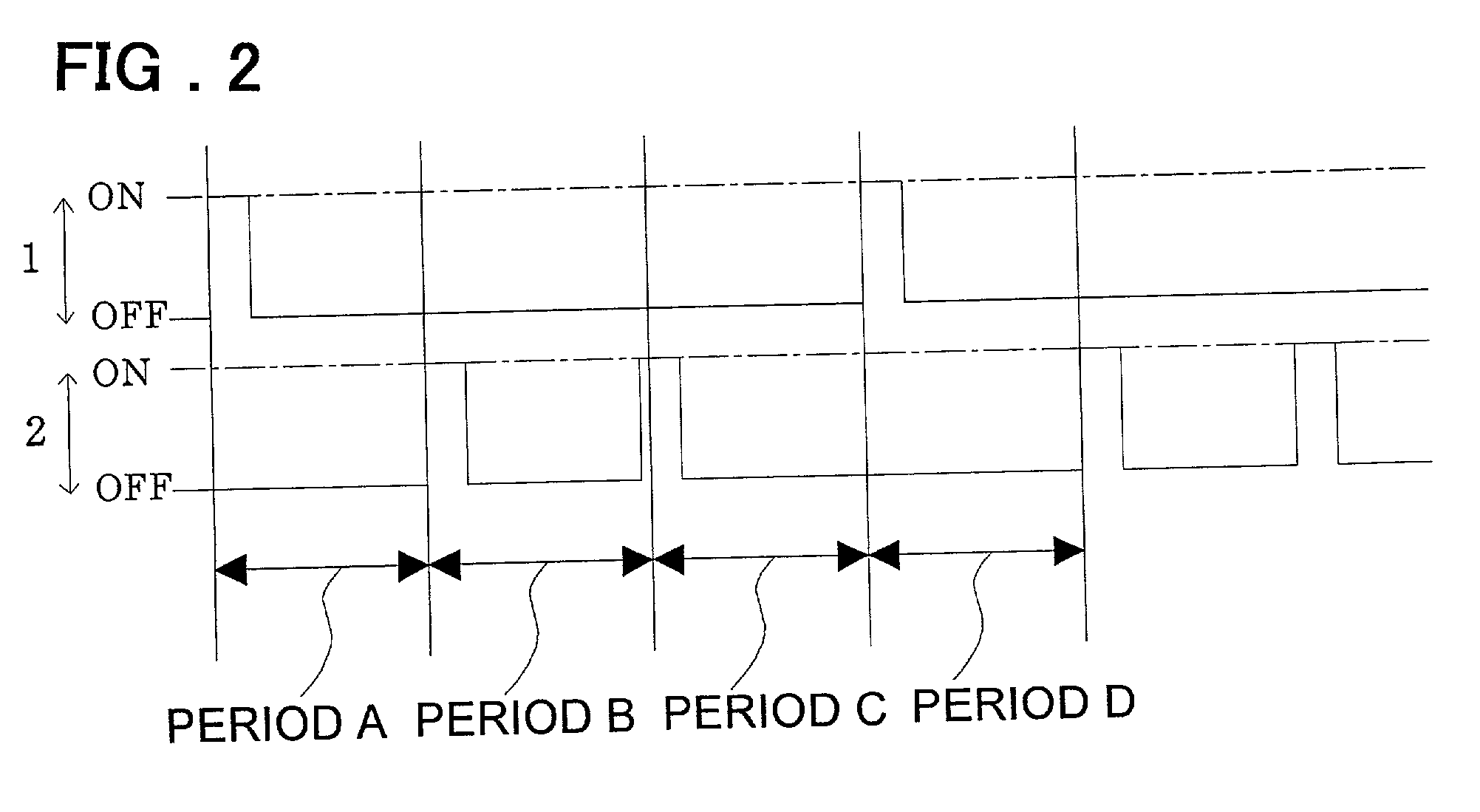

[0027] The duties of the switching element 1 the switching element 2, which control the ON / OFF state of those switching elements, are set in the DC / ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com