Device for traversing a flexible linear product for spooling

a technology of flexible linear products and traversing components, which is applied in the direction of transportation and packaging, thin material processing, filament handling, etc., can solve the problems of slowing down the spooling process, previous devices have not performed direction reversal of pivotally mounted guides, and previous traversing components, for the most part, have not addressed tension fluctuations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

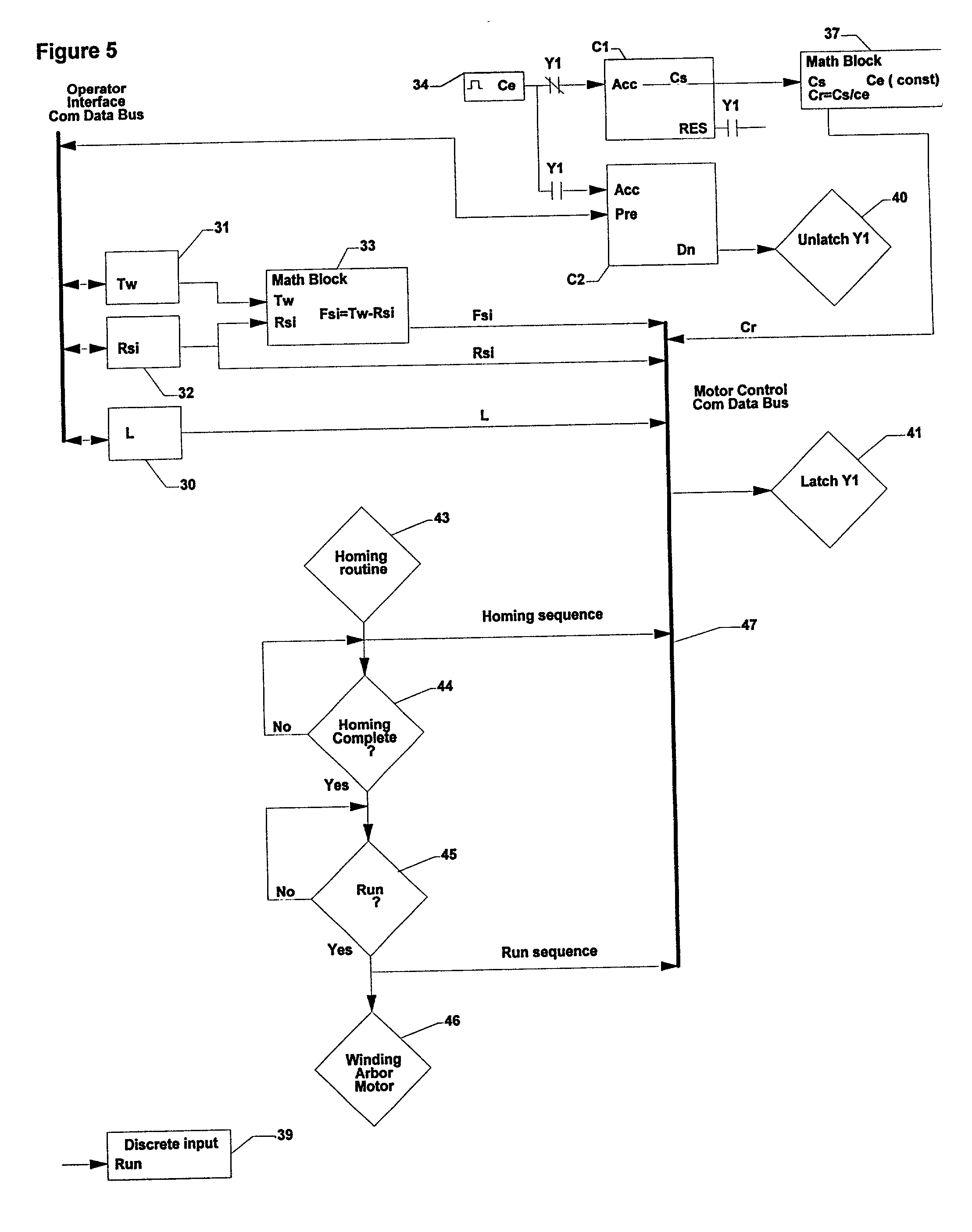

[0034] Let:

[0035] Rsi=-4 Tw=8 L=0.2 Cs=640 Cp=480 Tp=1800 r=10.75 5 Cr =Cs Cp Cr = 1.333

[0036] Fsi=Tw+Rsi Fsi=4 6 Da ( Y ) = a tan ( Yr 2 - Y 2 ) ( Tp 2 )

[0037] Y=Fsi-(L.times.Cr) Y=3.733

[0038] Da(Y)=101.607

[0039] If the rear stop (Rsi) is entered as -4 inches and the traverse width is 8 inches, the front stop (Fsi) position is calculated as 4 inches.

[0040] If the winding arbor count (Cs) is 640 steps and the arbor encoder PPR is 480, the arbor revolution count (Cr) is 1.333.

[0041] The desired traverse motion from the front stop is (Cr*L)=0.267 inches. This value (Y) is 3.733 inches from the origin.

[0042] When the traverse reaches the rear stop position, the logic commands the motor to a position that satisfies the equation Y=Rsi+(L*Cr), that is, the linear position is the rear stop in inches+(lay*arbor revs).

[0043] When the traverse reaches (Rsi) the accumulative count of (C1) is set to zero, the rotation of the traverse motor is reversed, and the equation Dti=Rsi+(L*Cr) is applied...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com