Retaining wall masonry block

a masonry block and retaining wall technology, applied in the field of masonry blocks, can solve the problems of difficult lifting, carrying and placing, and the type wall would not be as strong, and the pressure of the solid concrete wall cannot be the same,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

third embodiment

[0035] In a third embodiment, illustrated in FIG. 7, the centerline A' of the second cavity 238 of the body 212 extends inwardly from the side 218 and angles toward the back face 216. The angle B', between the centerline A' and a portion of the side 218 that is adjacent to the second opening 236 is less than 90 degrees. In this embodiment, the first cavity 228 remains as a mirror image of the second cavity 238.

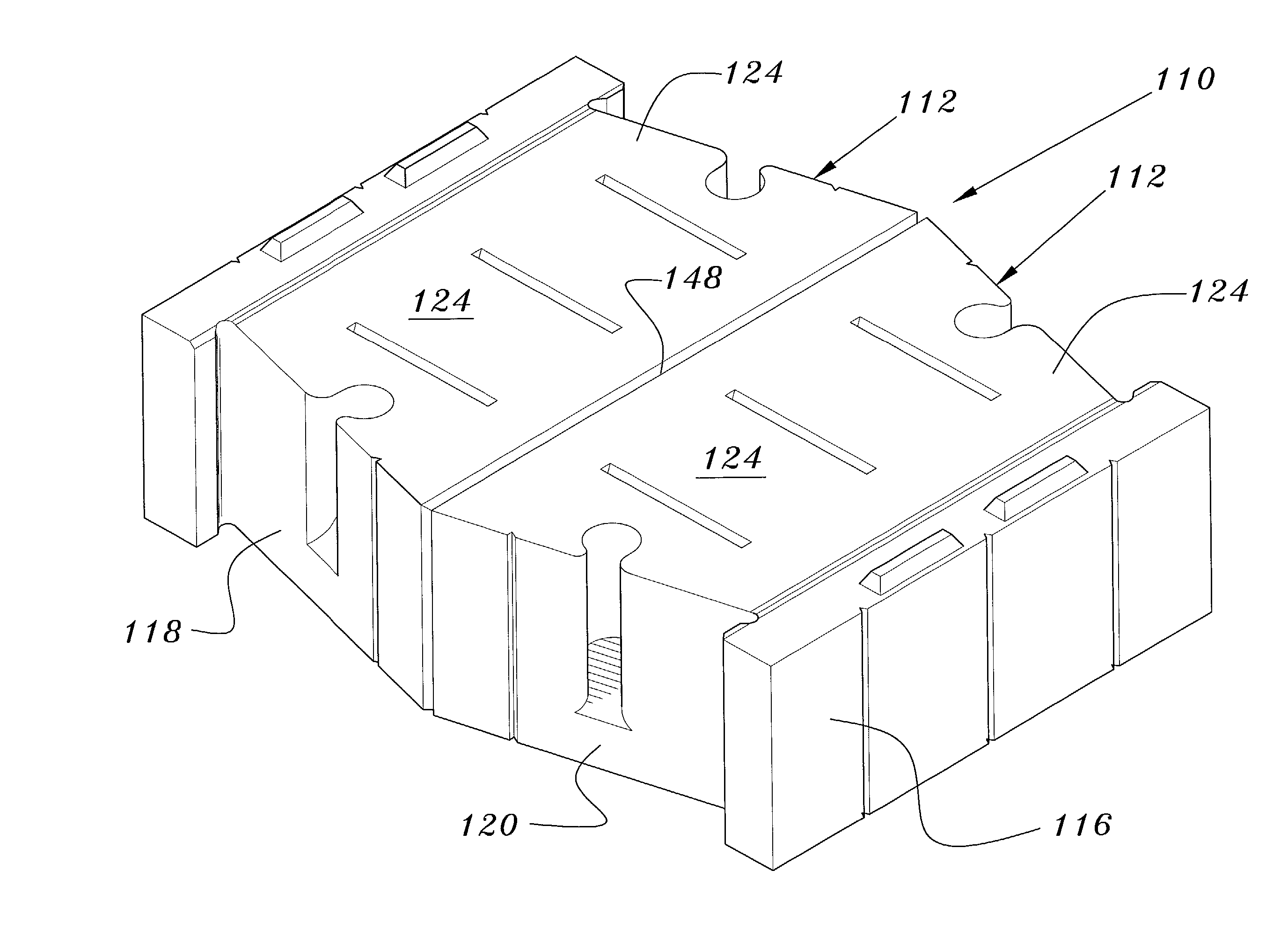

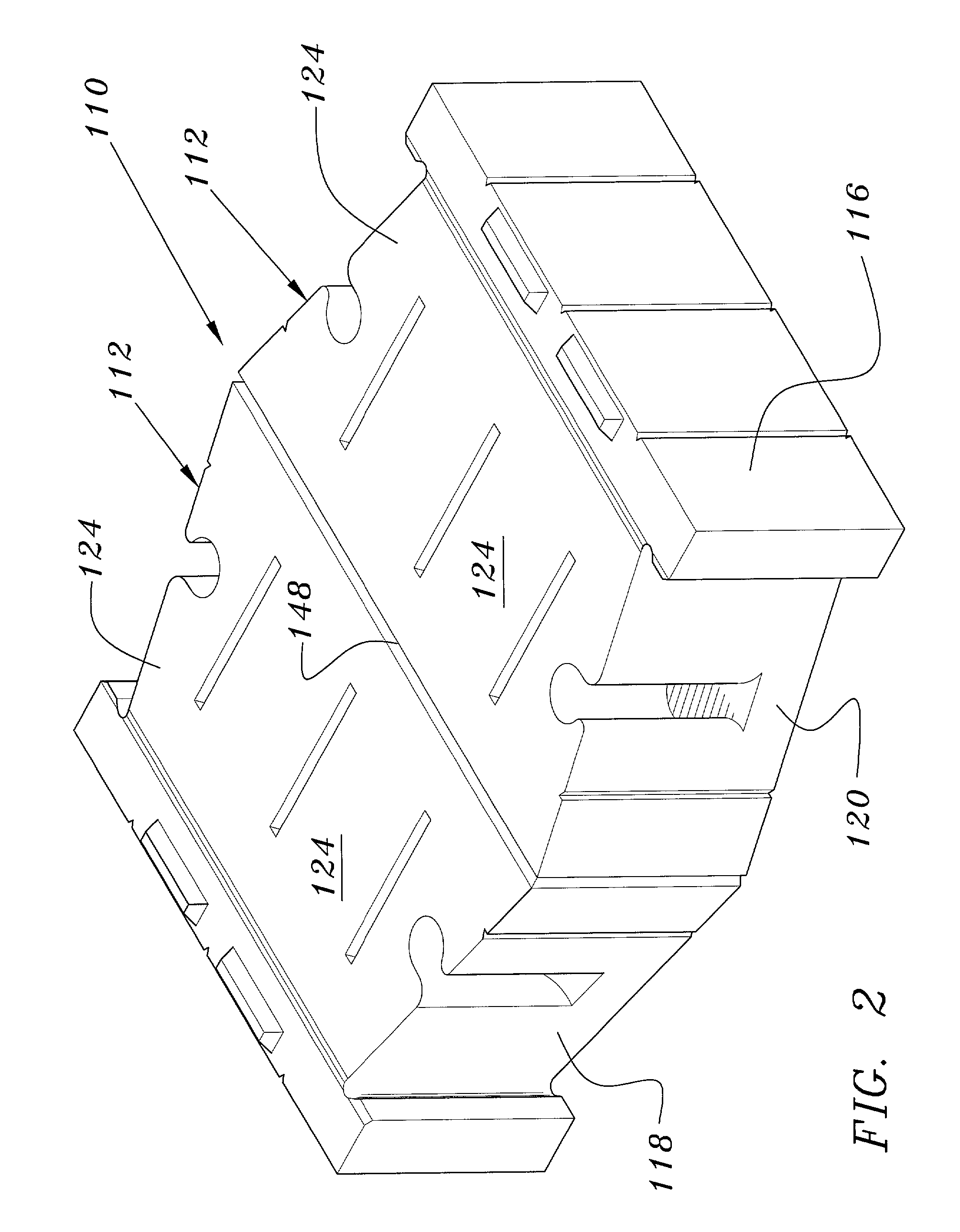

embodiment 110

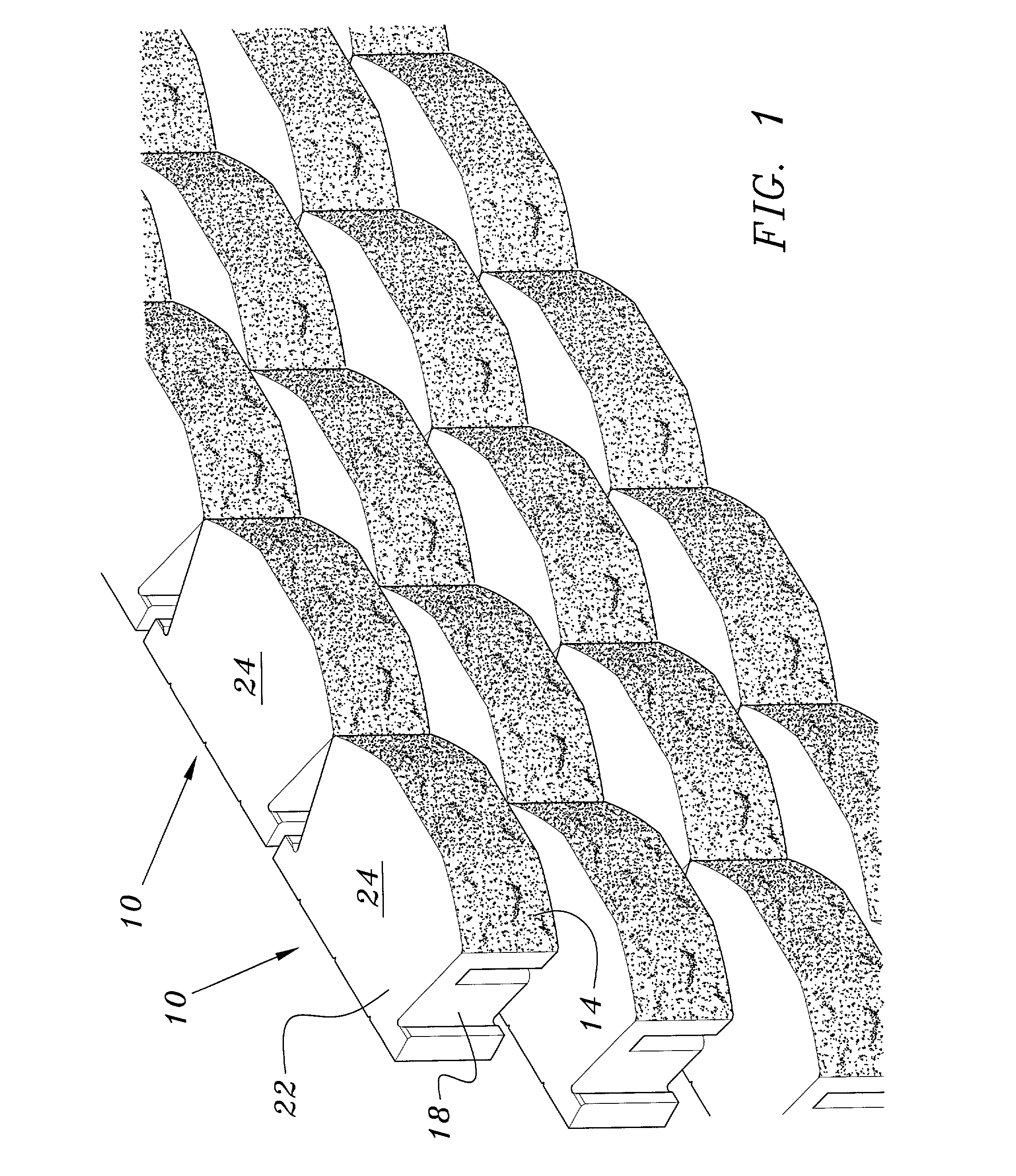

[0036] As can be seen in FIG. 6, the bottom face 24 of the body 12 has a plurality of grooves formed therein. There is a least one groove 40 extending along a portion of the bottom face 24 generally perpendicular to the front face 14 and perpendicular to the back face 16. In the embodiment illustrated there are three such grooves spaced apart from one another. There is also a groove 42 extending along the bottom face 24 that is generally parallel with and proximal to the back face 16. As seen in FIG. 4 and FIG. 5, a groove 44 is formed in side wall 18 and side wall 20, which is proximal the front face 14 and parallel thereto. As seen in FIG. 6 and FIG. 10, at least one groove 46 is formed in the back face 16. In a preferred embodiment, this groove lies in the same plane as a corresponding groove 40 in the bottom face 24. Also, in a preferred embodiment, as illustrated, there are three grooves 46, each lying in a plane with a corresponding groove 40 in the bottom face 24. In the embo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com