Drywall finishing system

a finishing system and drywall technology, applied in the field of drywall construction, can solve the problems of requiring an extended drying time, thick layer will tend to experience shrinkage and cracking, and thick wedges of mud f are built up on both sides of the corner member at significant labor and material costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

first embodiment

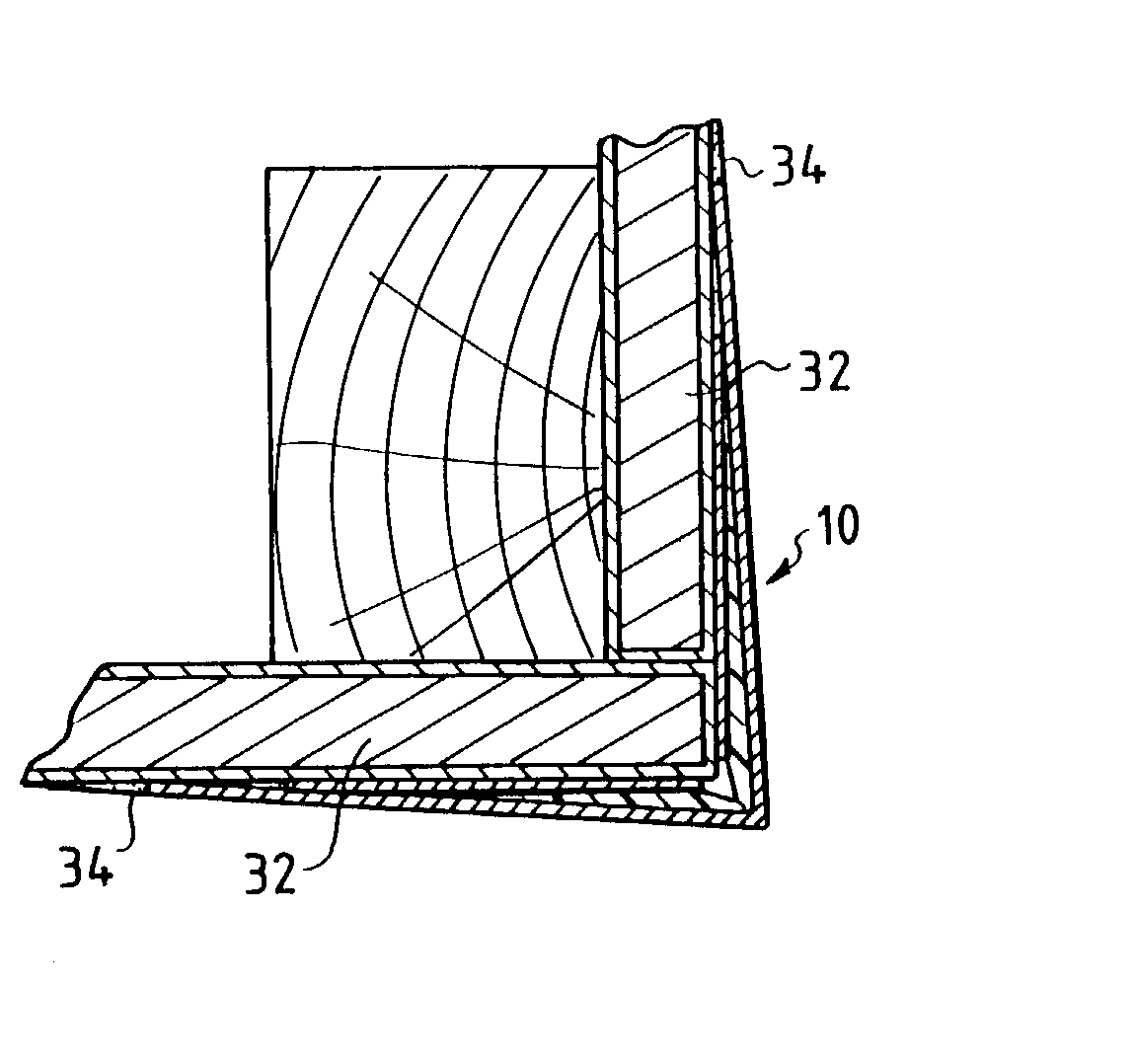

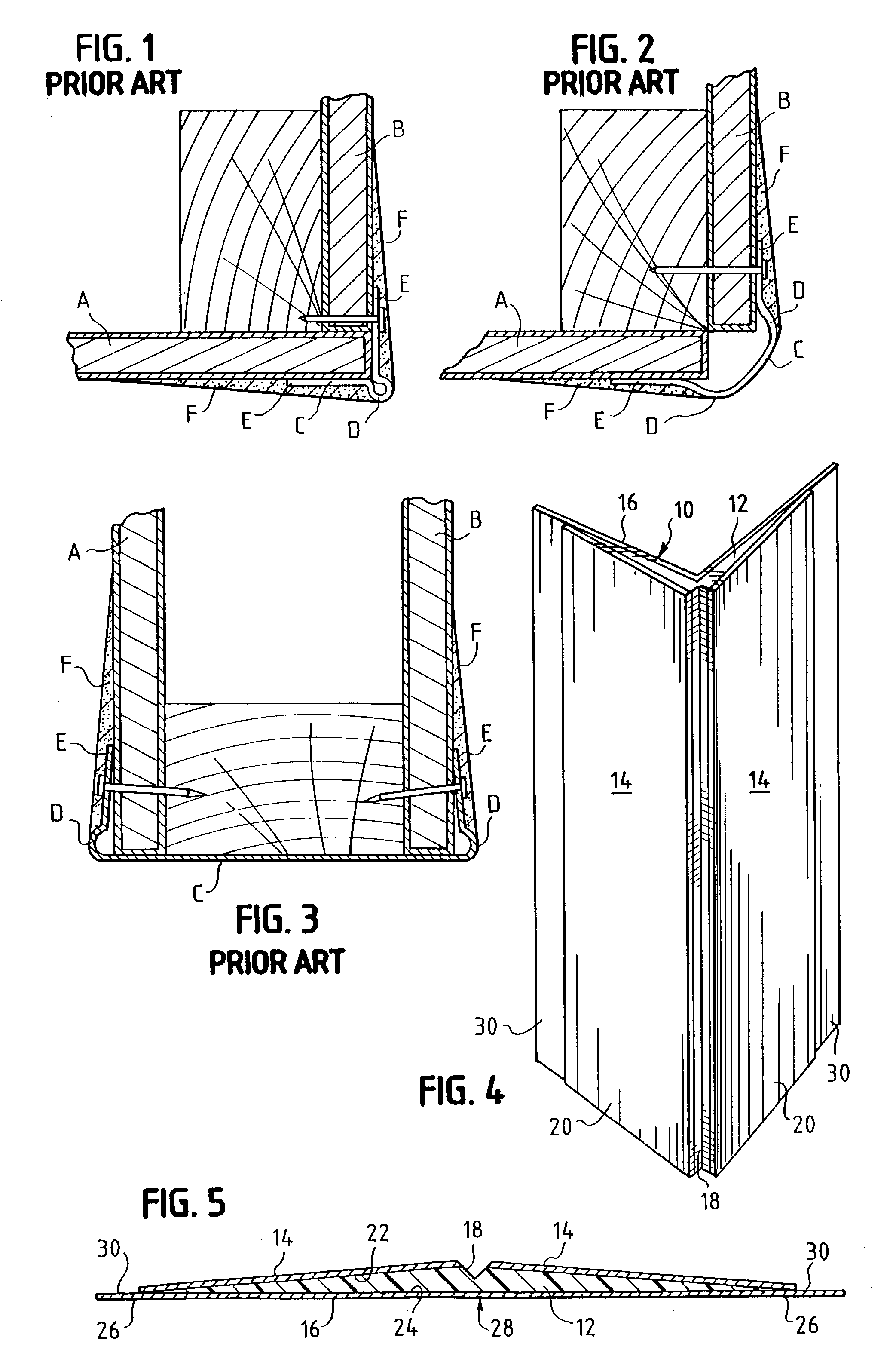

[0052] Referring to FIGS. 4 and 5, the present invention, that will be called "Ultra-Flex", is seen generally at 10. This embodiment can be used for inside or outside corners. Its construction is that of an elongated semi-rigid member 12 with an interior layer of covering material 14 and an exterior layer of finishing material 16 laminated thereto. The semi-rigid member 12 can be plastic, metal, or other flexible, but strong material, with high impact plastic such as that used to construct modern cola bottles being preferred. The member can be supplied in 10 or 12 foot lengths, or any other convenient length, or it can be supplied on a roll of 100 feet or any other convenient length. Running the length of the member is a groove 18. The groove divides the piece into two flanges 20 that can be repeatedly bent to form any angle from about 15 degrees to about 345 degrees. In this manner, the piece can be bent to match any inside or outside corner. The elongated semi-rigid member has a f...

second embodiment

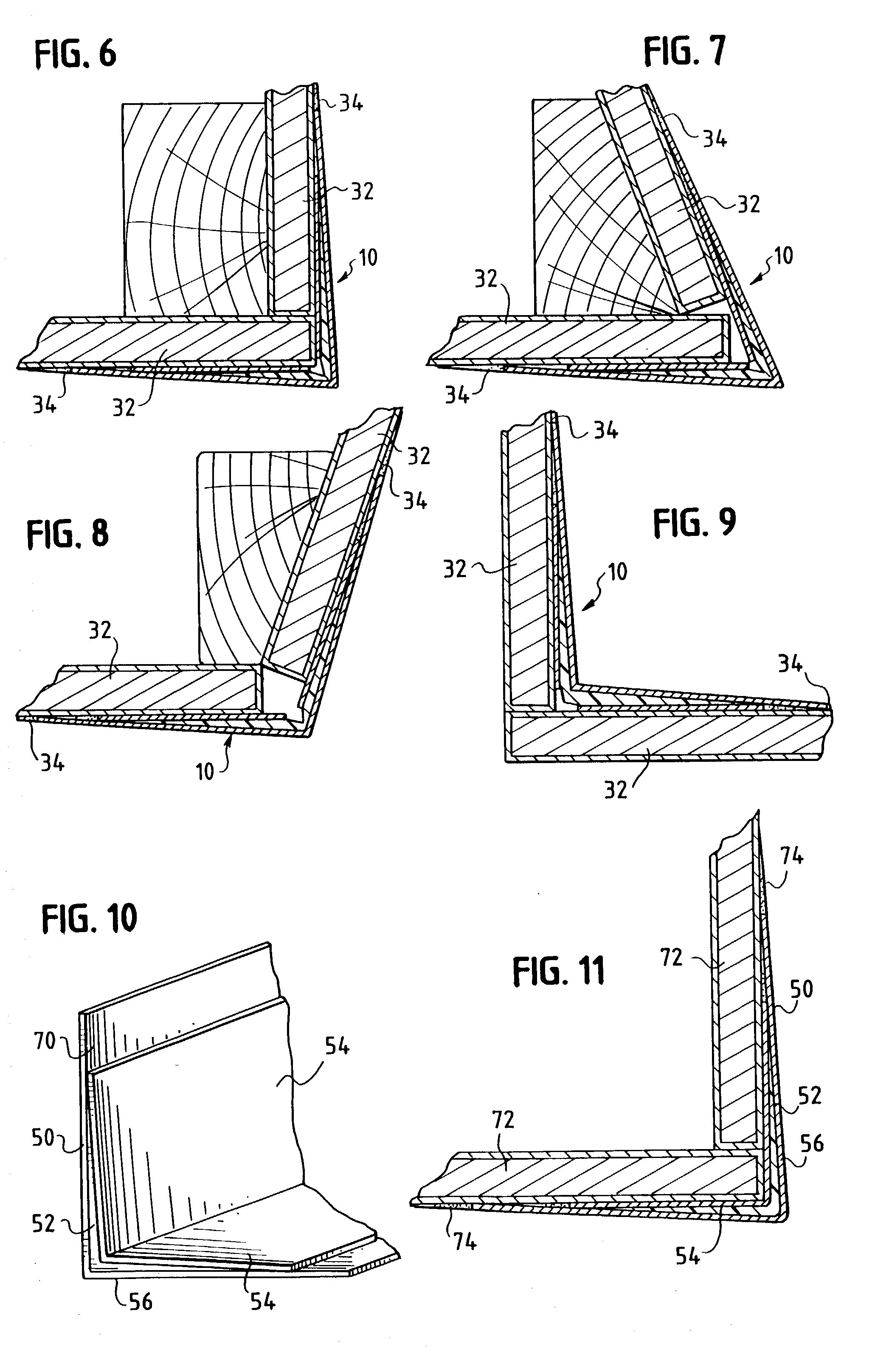

[0067] FIG. 11 shows the trim piece of the second embodiment installed on a drywall outside corner. Drywall sheets 72 form a conventional right angle, outside corner. The trim piece 50 is continuously adhered to the drywall with mud as described above. The edges between the trim piece 50 and drywall 72 are feathered with a relatively small quantity of mud 74 to provide a smooth surface. The exterior surface of the trim piece is not coated with mud, however, as was customary with prior art corner beads. Compare FIG. 11 to FIG. 1. There is a dramatic reduction in the amount of drywall mud utilized--up to 75% less mud. The reduction in the quantity of mud directly translates to corresponding dramatic reductions in the amount of drying time and labor.

third embodiment

[0068] FIGS. 12 and 13 illustrate the trim piece 110 of the invention comprising a rounded or bullnose right angle outside corner piece. Trim piece 110, as with the first two embodiments, comprises a semi-rigid member 112 with an interior layer of covering material 114 and an exterior layer of finishing material 116 laminated thereto. The semi-rigid member 112 can be preformed with a permanent 88-90.degree. radius 118. The exact angle is not critical and can be preformed to other angles encountered in the field such as 135 degrees, or any other angle. The preferred material is high impact plastic, with a uniform thickness of 0.057 inches in the radius. The radius is a true circular arc--there are no ridges or beads. The semi-rigid member 112 further comprises flanges 120 that can taper laterally from a maximum thickness at radius 118 to a minimum thickness near lateral edges 126, or can taper laterally from maximum thickness at a point slightly away from the radius 118 to a minimum ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com