Guided clamps for quick easy opening and closing of dispenser outlet

a dispenser outlet and guide technology, applied in the direction of flexible container closure, pliable tubular containers, transportation and packaging, etc., can solve the problems of not being able to dispense products from thin film plastic flexible bags, not being able to use free flow discharge of solid materials,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

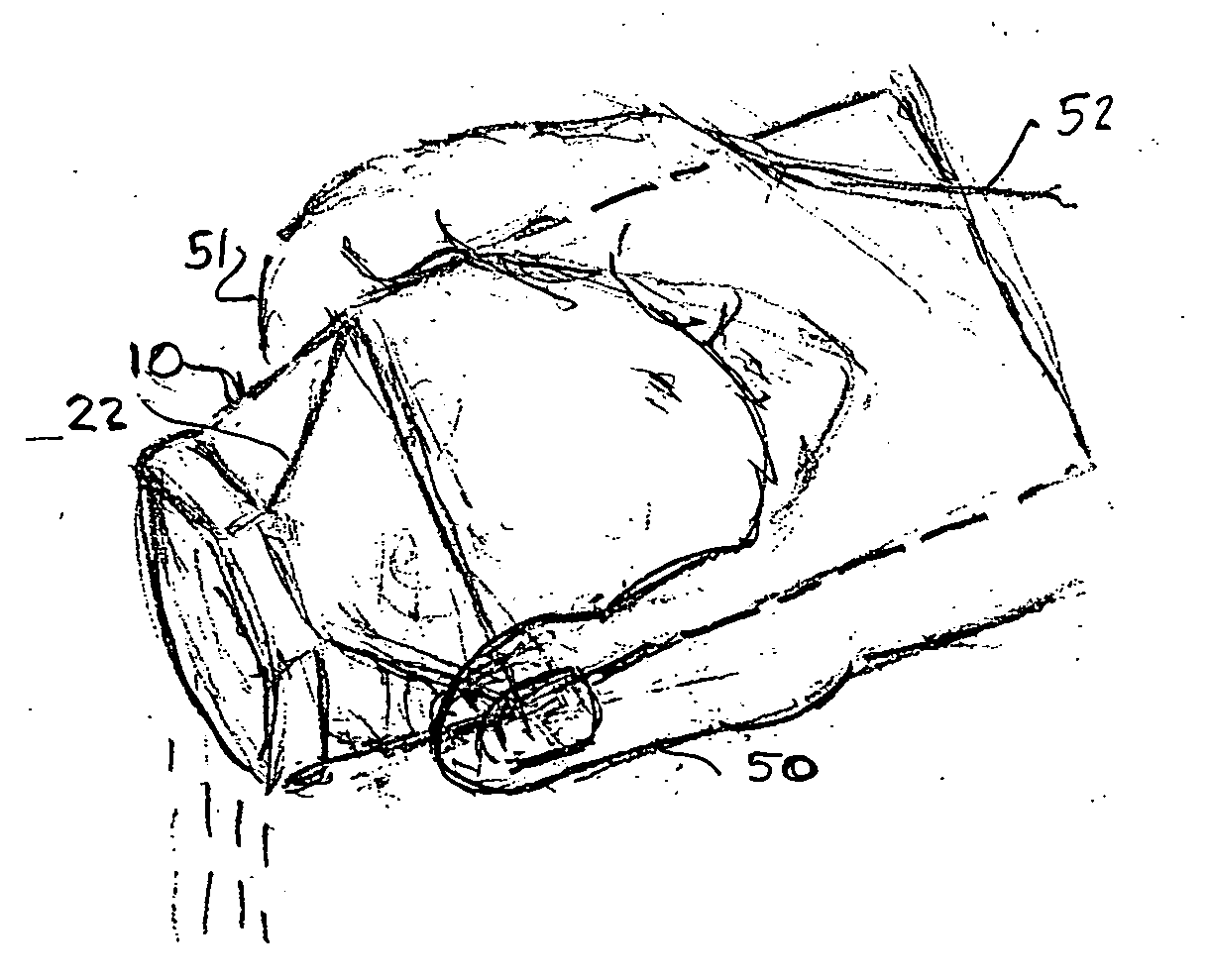

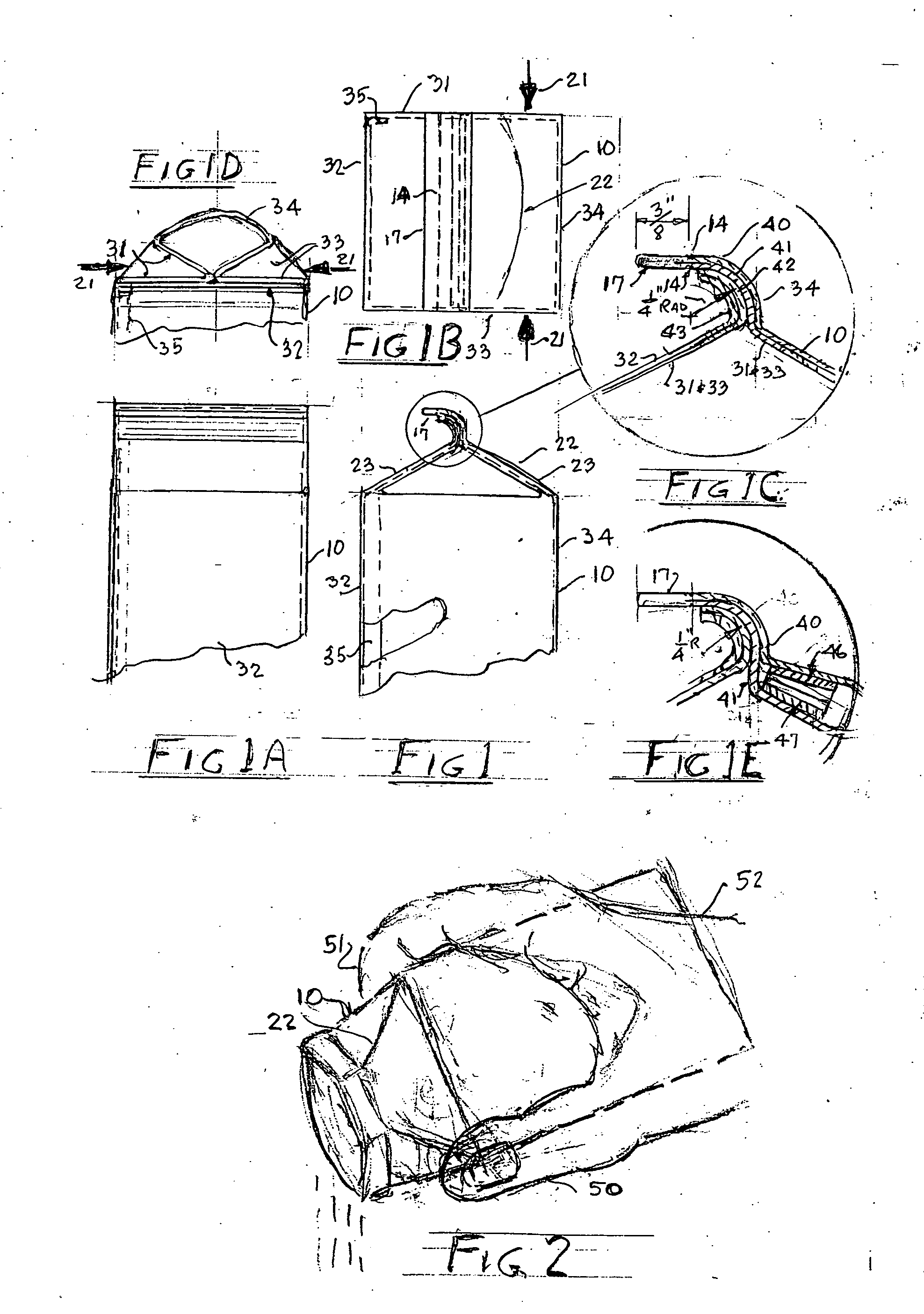

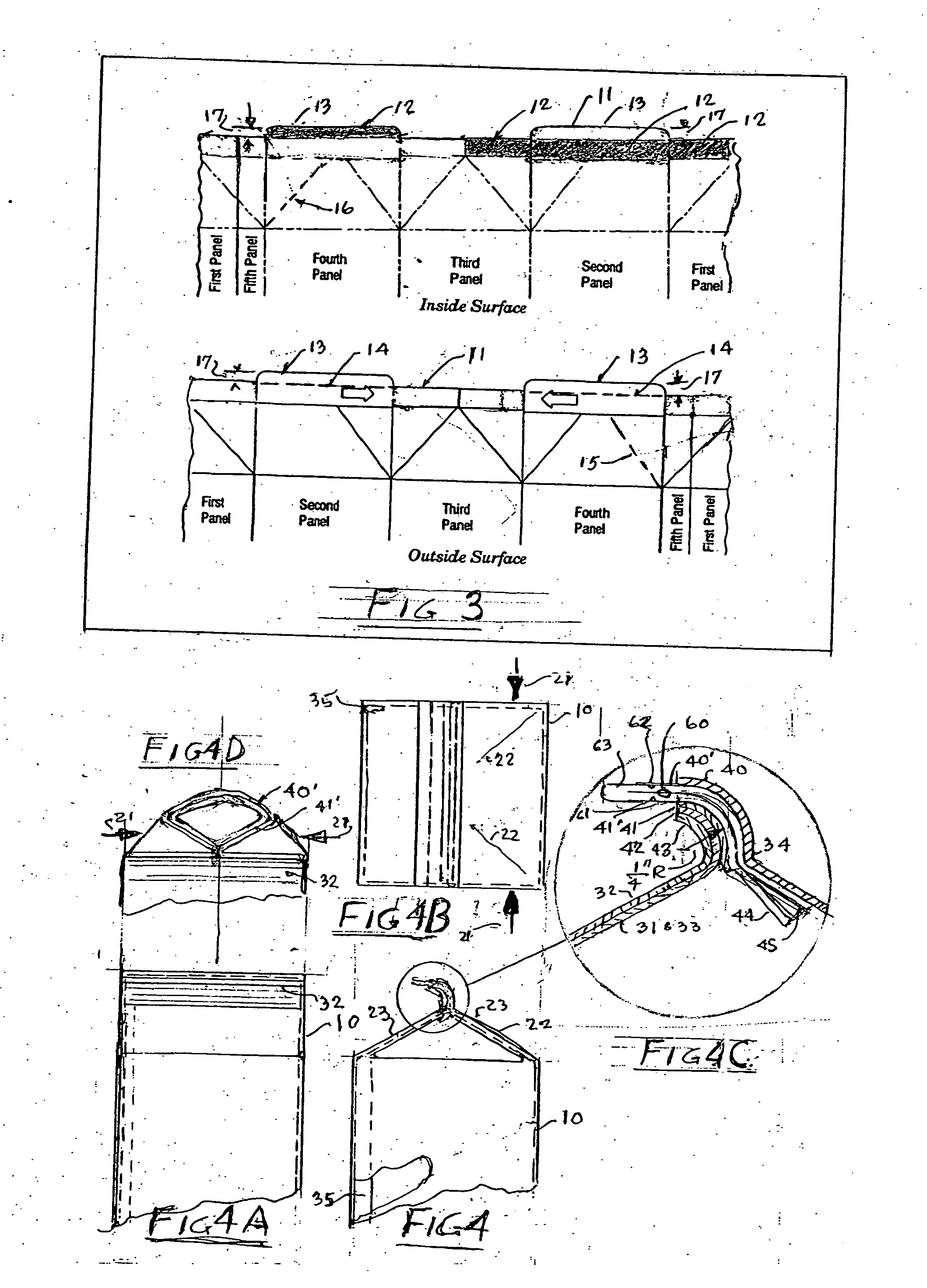

[0064] The following embodiments describe novel ways to eliminate problems with opening and reclosing dispenser outlets of flexible thin film plastic bags, particularly those having “Zip-Loc”, or equal reclosable male and female interlockijng joints. Depending upon the contents to be stored within the flexible plastic bag most preferred embodiment appears to be FIG. 2 using pre-manufactured flexible bags having clear line single track seal top bags which protects during shipment and against pilfering of contents until the customer performs the initial squeeze to open operation.

[0065]FIG. 1 is a split elevation of the top portion of a preformed conventional plastic bag 10 with standard reclosable closure 9 having a bag opening under 6 inches in length; aided for opening and closing by the addition of throat guide mouth attachments 17 and 18 when fusion welded 7 at their opposing outer edges 22, with plastic bag 10 sheets 19 and 20 causes said bag to taper 22′ downwardly from top bag...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| sizes | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com