Metal picture frame with dust cover

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

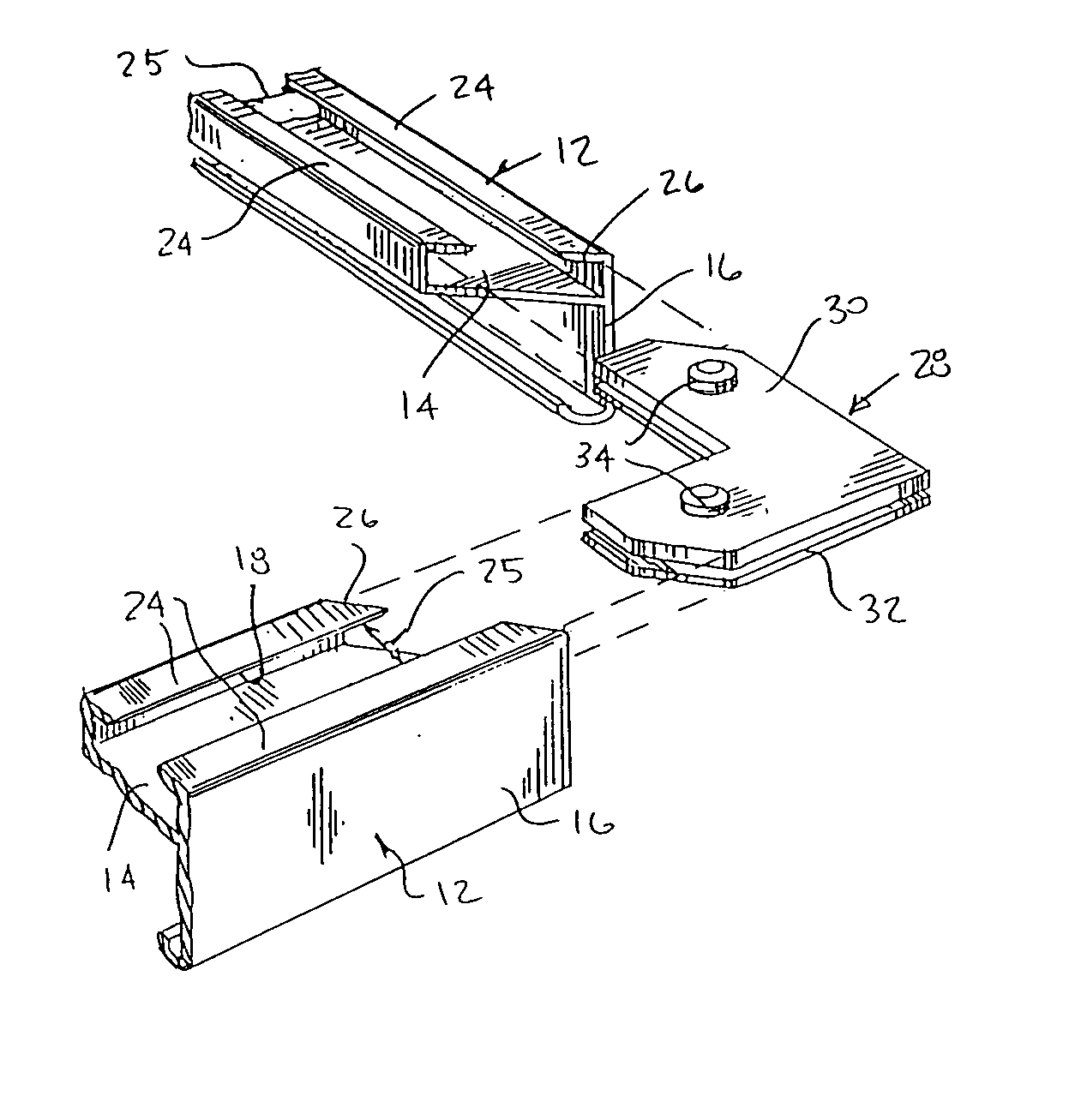

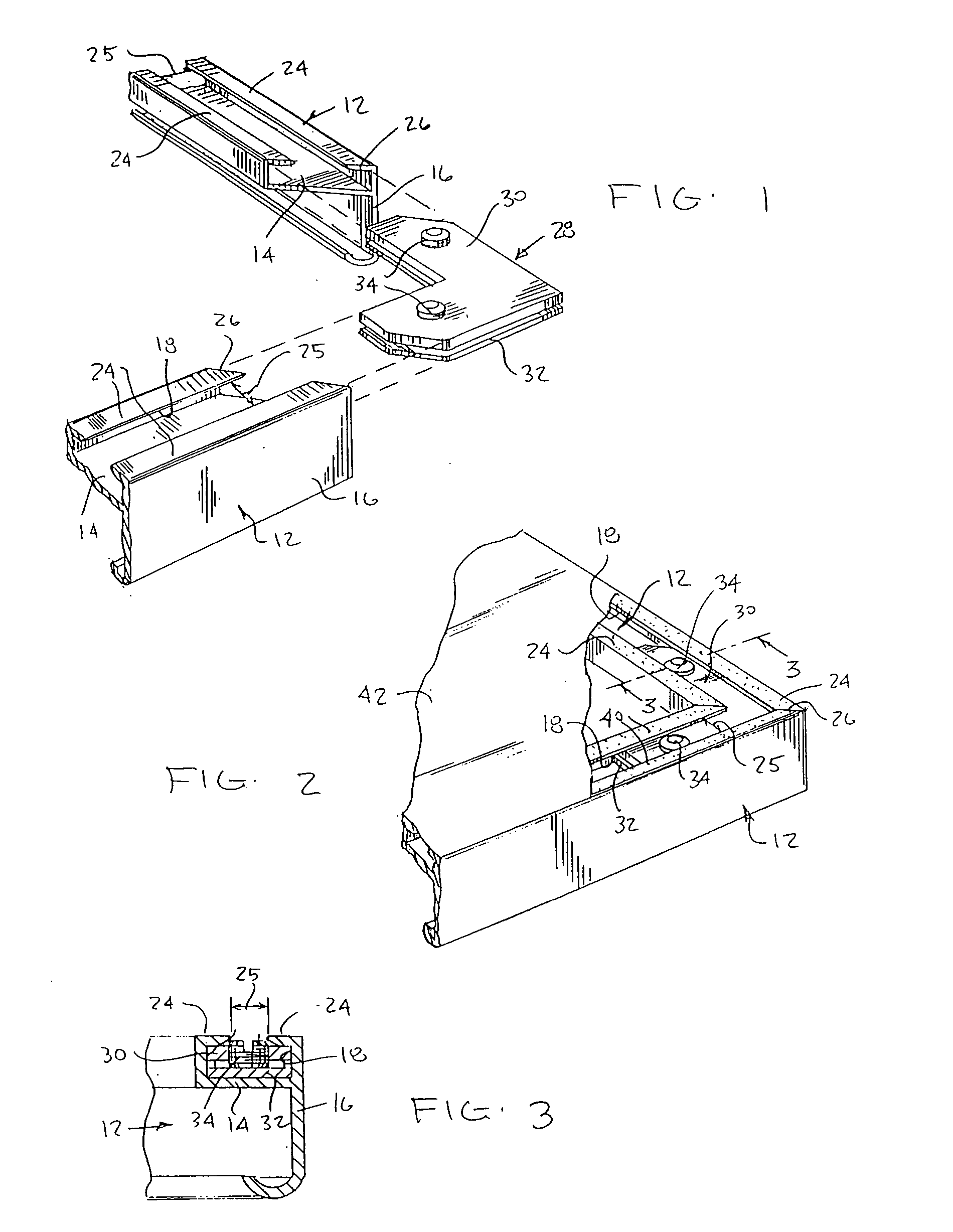

[0008] A picture frame comprises four frame sections 12 preferably extruded from aluminum. The frame sections 12 have identical cross sections and, as shown in FIG. 1, include an inwardly directed supporting flange 14, an outer wall 16 and a receiving channel 18. The receiving channel 18 is rectangular in cross section and includes two opposed lips 24 which are spaced apart to define a gap 25 extending the length of each section.

[0009] The ends of each section are mitered as illustrated at 26 and adjacent frame sections are joined together at their mitered ends and secured in place by a corner piece 28. The corner piece 28 includes an L-shaped screw plate 30 and an L-shaped backing plate 32. Screw plate 30 includes two threaded holes, one in each leg, which receive set screws 34. Tightening of the set screws 34 forces the plates 30 and 32 apart thereby clamping the adjacent frame sections 12 together.

[0010] The gap 25 between the edges of the lips 24 at the back of the frame secti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com