High comfort mattresses and methods for constructing them

a mattress and comfort technology, applied in the field of mattresses, can solve the problems of poor night's sleep, unfavorable design, and convolutions losing their cushioning effect, and achieve the effects of reducing pressure points, luxurious feeling, and reducing pressure points

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

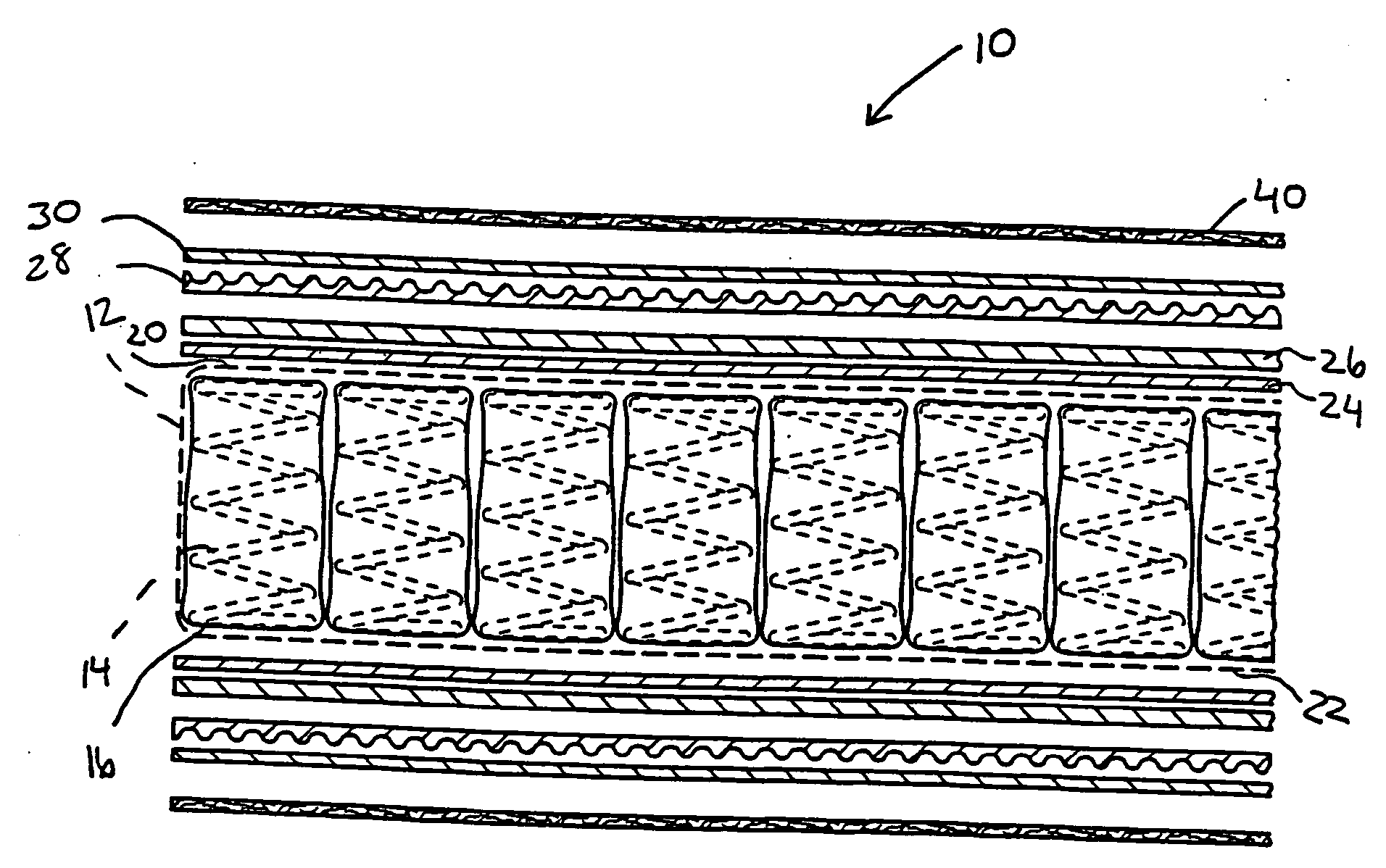

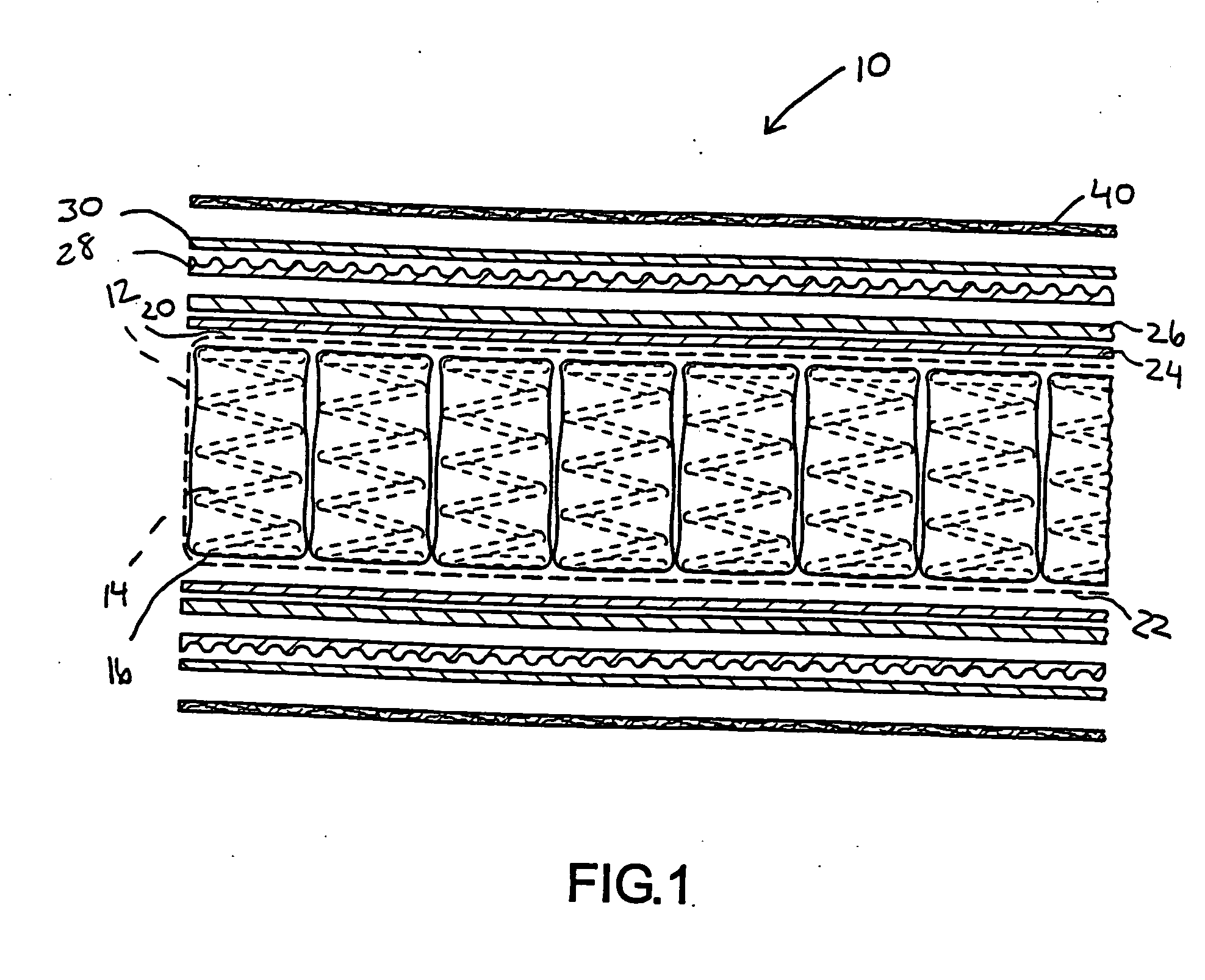

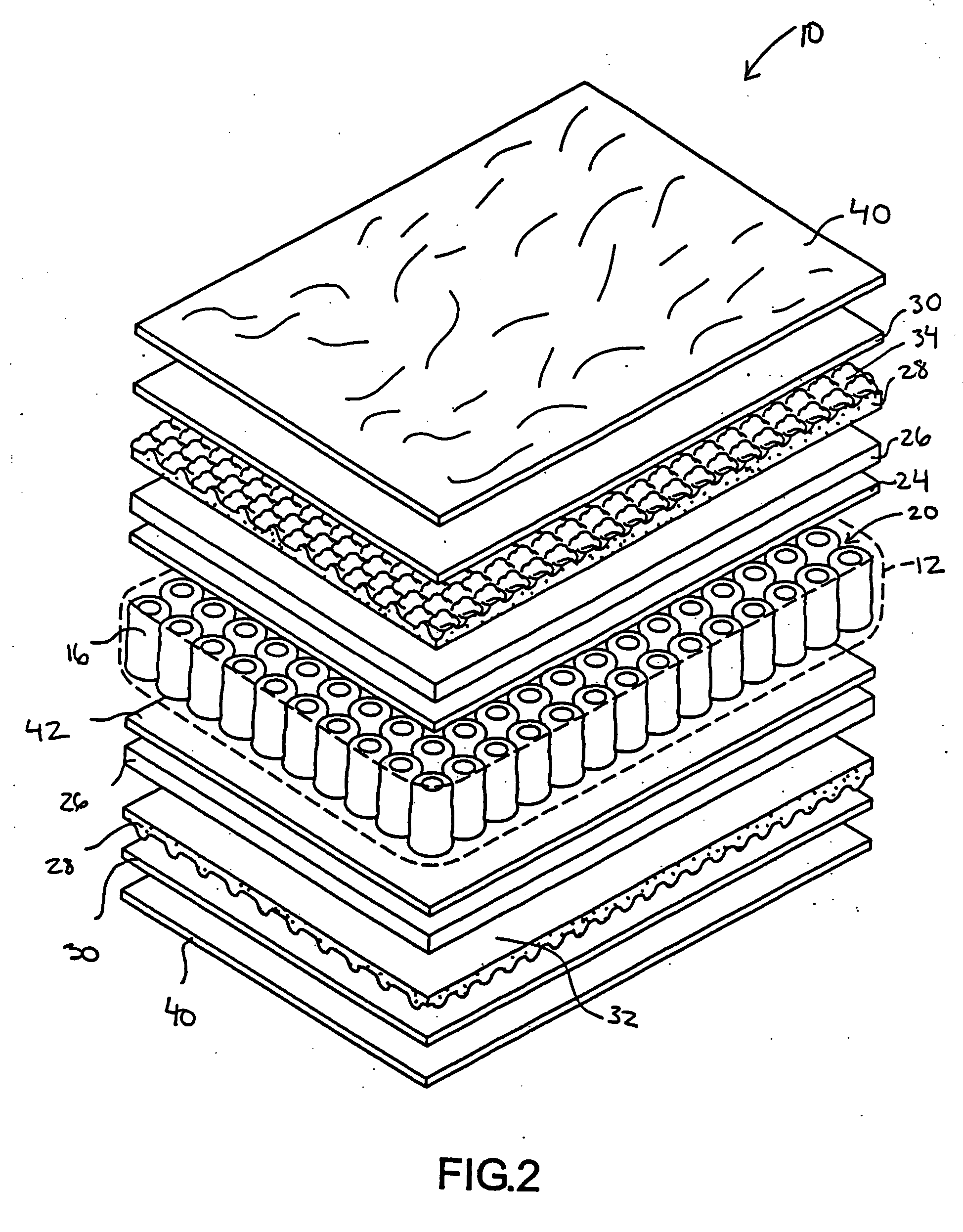

[0019] The invention provides a variety of mattresses that provide a high level of comfort at reasonable manufacturing costs. The mattresses may utilize a variety of cores and a variety of padding layers arranged in a variety of ways. One example of a high comfort mattress is illustrated schematically in FIG. 1.

[0020] Mattress 10 utilizes a core 12 that provides the basic layer of support to the user's body. Mattress 10 may be used with essentially any type of core 12. For example, core 12 may comprise springs 14 that are encased in fabric pockets 16. Other cores include traditional open coil springs, latex rubber cores, visco-elastic cores, polyurethane cores, air bladders, waterbed cores, and the like. Hence, the invention is not intended to be limited to only a specific type of core. A border rod may be used to couple the core to an adjacent layer, although in some instances a foam casing or other border material may be placed around the core and the other layers.

[0021] For con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com