Footwear closure system with zonal locking

a closure system and shoe technology, applied in the field of footwear, can solve the problems of not being optimal or suitable for all applications, not being suitable for known locking systems, and not being suitable for fittings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

second embodiment

[0032]FIG. 4 is a top view of a closure 400 of a snowboard boot using the present invention. Once again, the closure 400 is a closable opening in an upper of a boot shell, boot liner, or other footwear, such as an opening that secured over a tongue across a top of the wearer's foot or lower extremity. The closure 400 includes a closure line 410 allowing the closure 400 to be closed to secure a boot or other article of footwear (not shown) on the wearer's foot and ankle. The closure line 410 suitably is a lace or a cable. The closure line 410 engages securing points 420 on opposing sides of the closure 400 so that, when tension is applied to the closure line 410, the closure is secured to the user's foot.

[0033] As in the case of the first embodiment of the present invention, a second embodiment of a zonal lock 430 enables the closure line 410 to maintain a first degree of tension in the first zone 440 different from a second degree of tension in the second zone 450. More specifically...

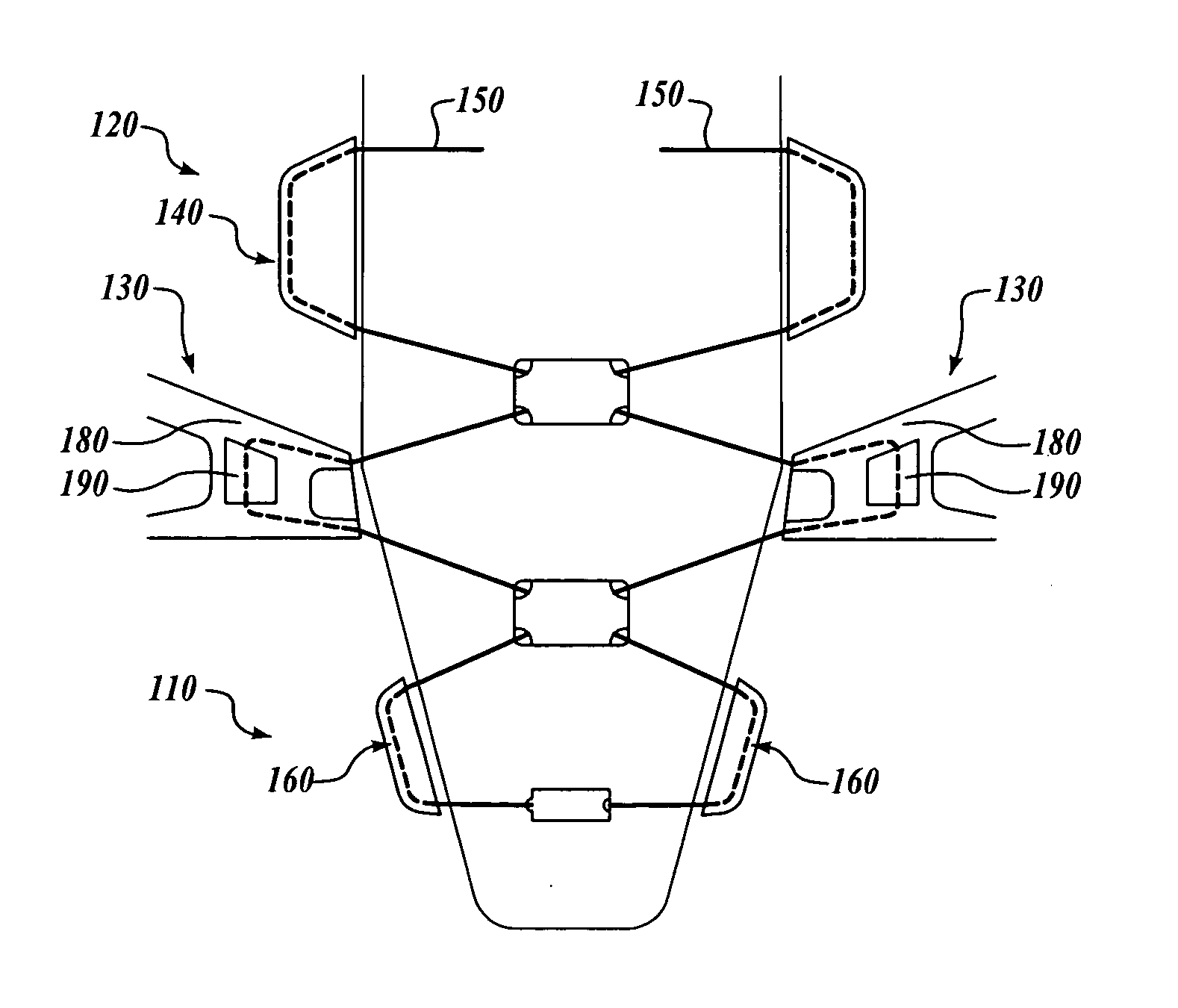

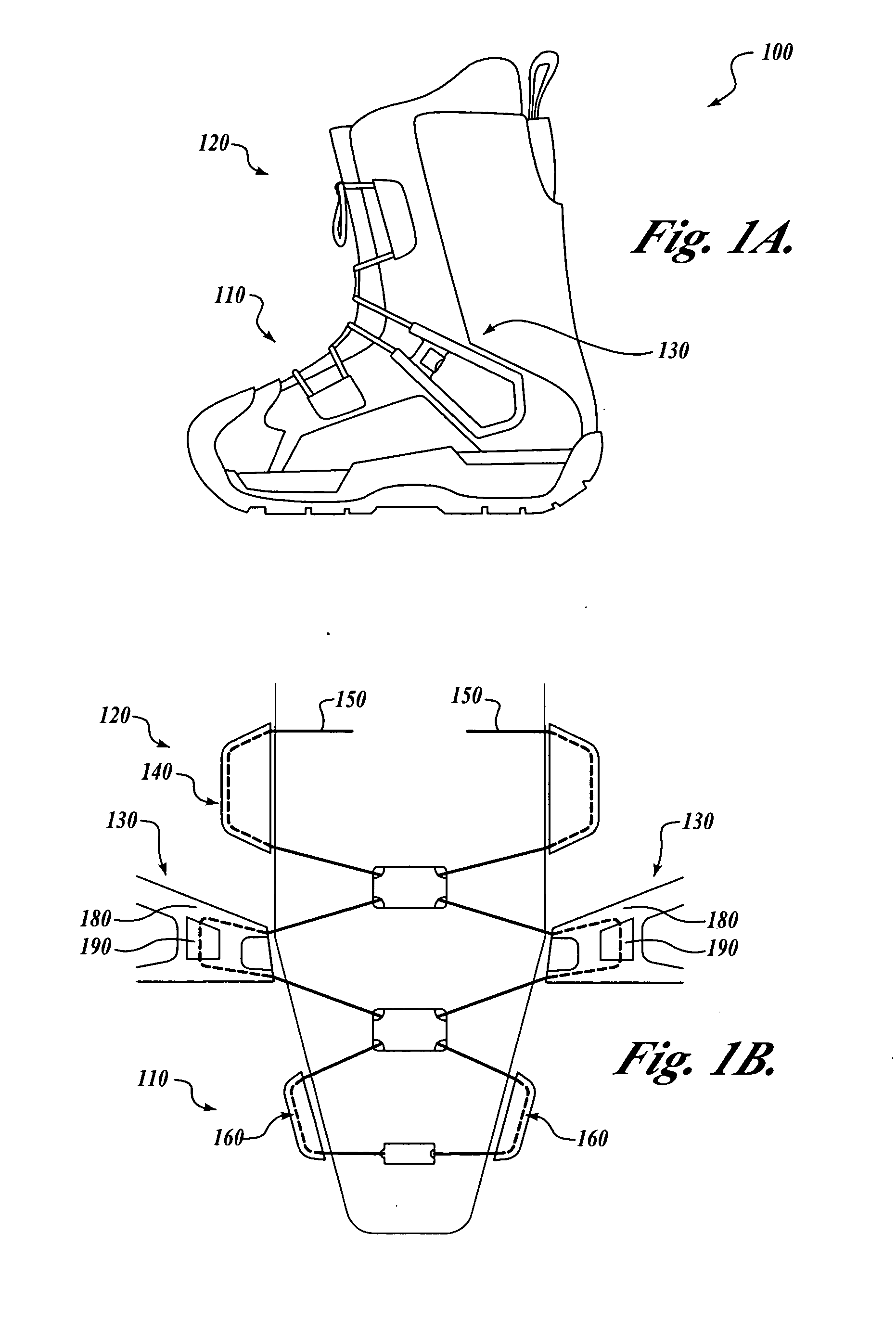

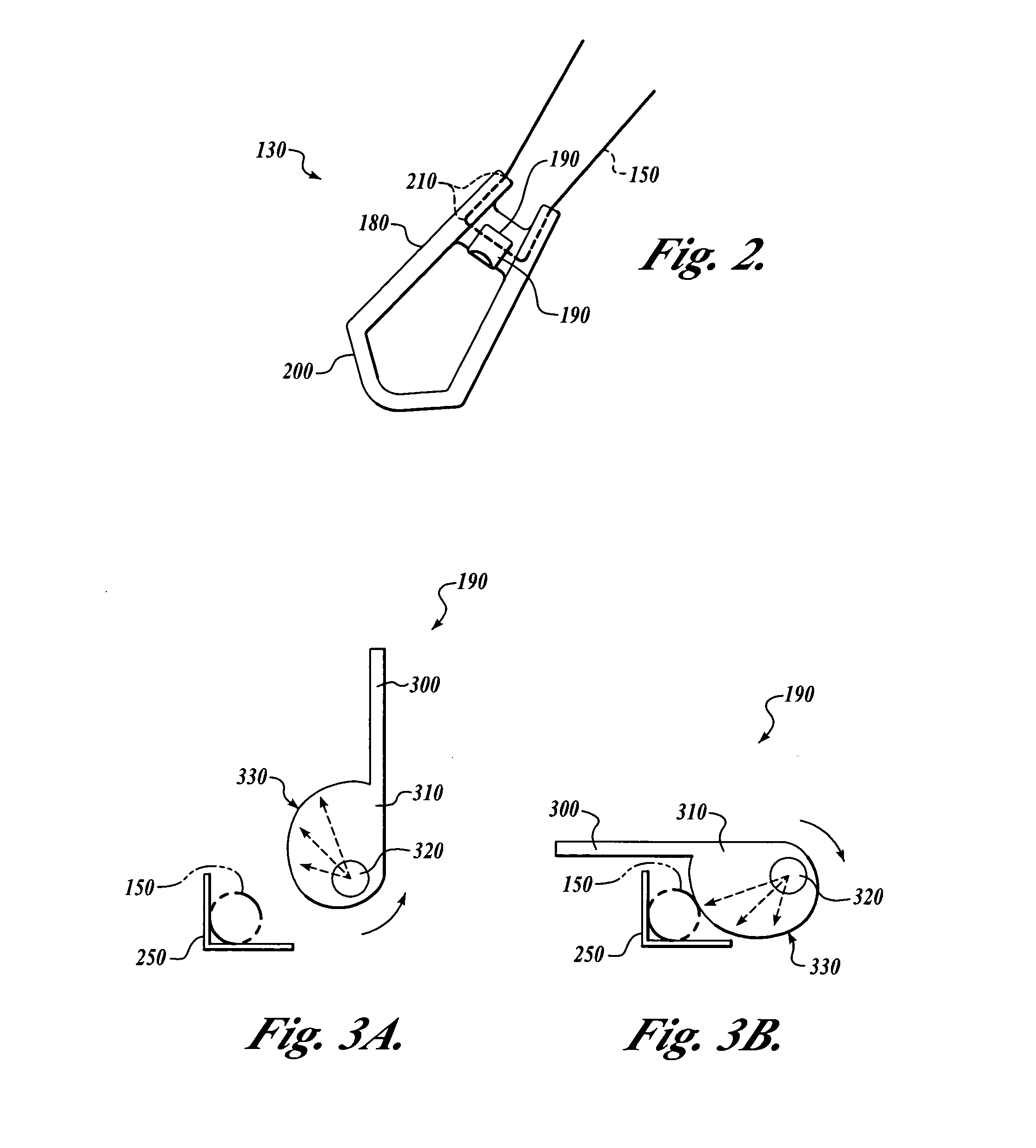

first embodiment

[0037] Also, the rotatable cylinder 500 of the zonal lock 430 is desirably equipped with a gripping ring 540 at a distal end of the rotatable cylinder 500. The gripping ring 540 facilitates a wearer being able to turn the rotatable cylinder 500 when it is in an unlocked position to be able to adjust tension in the closure line 410 in a zone 440 and 450 on either side of the zonal lock 430. As in the case of the invention (FIGS. 1A-3B), one or more additional zones could be added to provide for more than two zones having different degrees of tension in the closure line. An additional zone can be added adjacent to either the first zone 440 (FIG. 4) or the second zone 450 and separated from the adjacent zone by an additional zonal lock 430.

[0038]FIG. 6 is a flowchart of a routine 600 for using a single zonal lock 130 (FIGS. 1B-3B) and 430 (FIGS. 4 and 5) to maintain zonal tightening and locking of two zones of an article of footwear. It will be appreciated that the routine 600 suitably...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com