Methods and structures for sealing air gaps in a building

a technology for sealing air gaps and building walls, applied in the direction of coatings, buildings, building components, etc., can solve the problems of gaps between the top plates of framed walls and drywall, significant air leakage, and few people even know that the gaps are presen

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

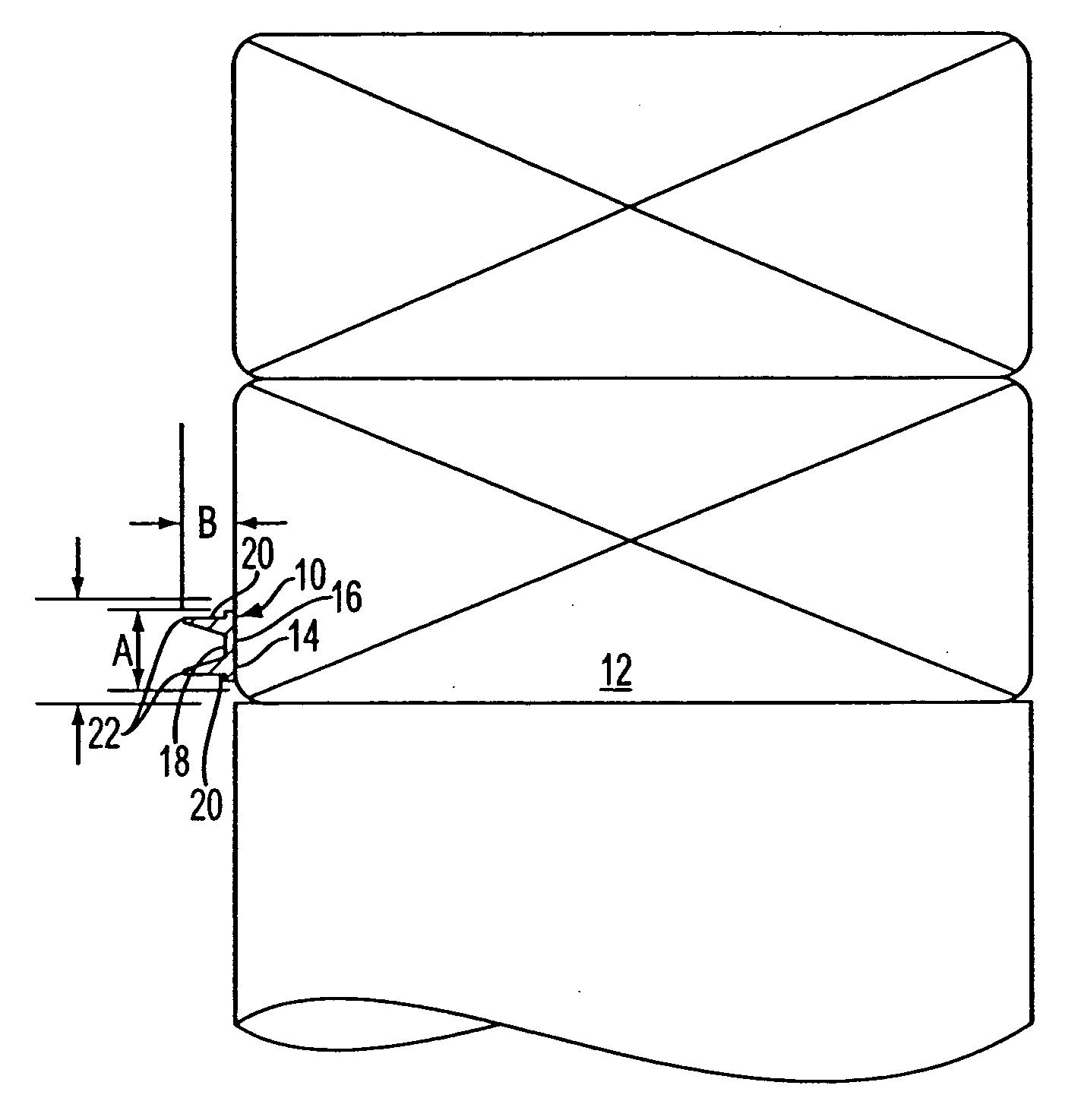

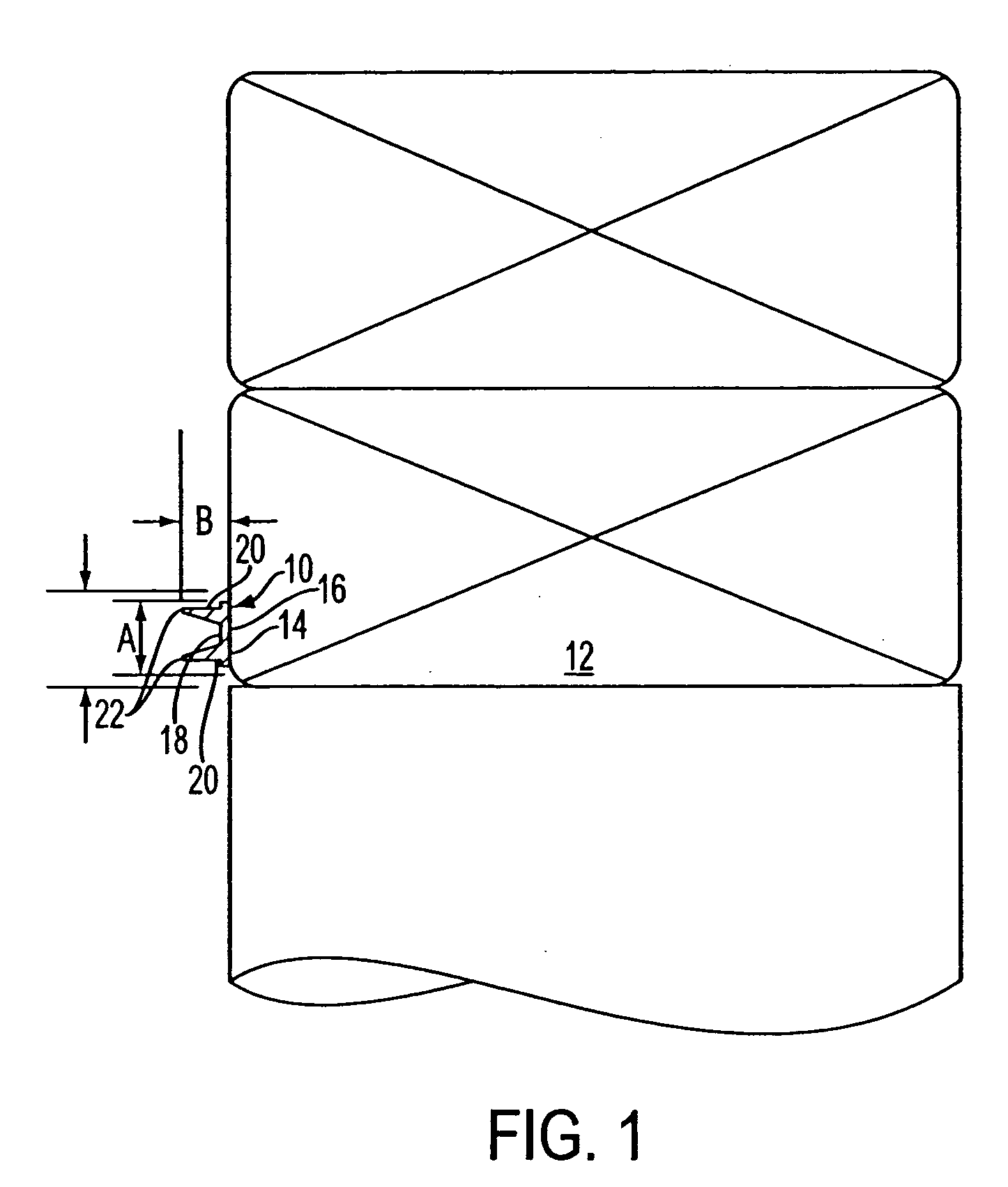

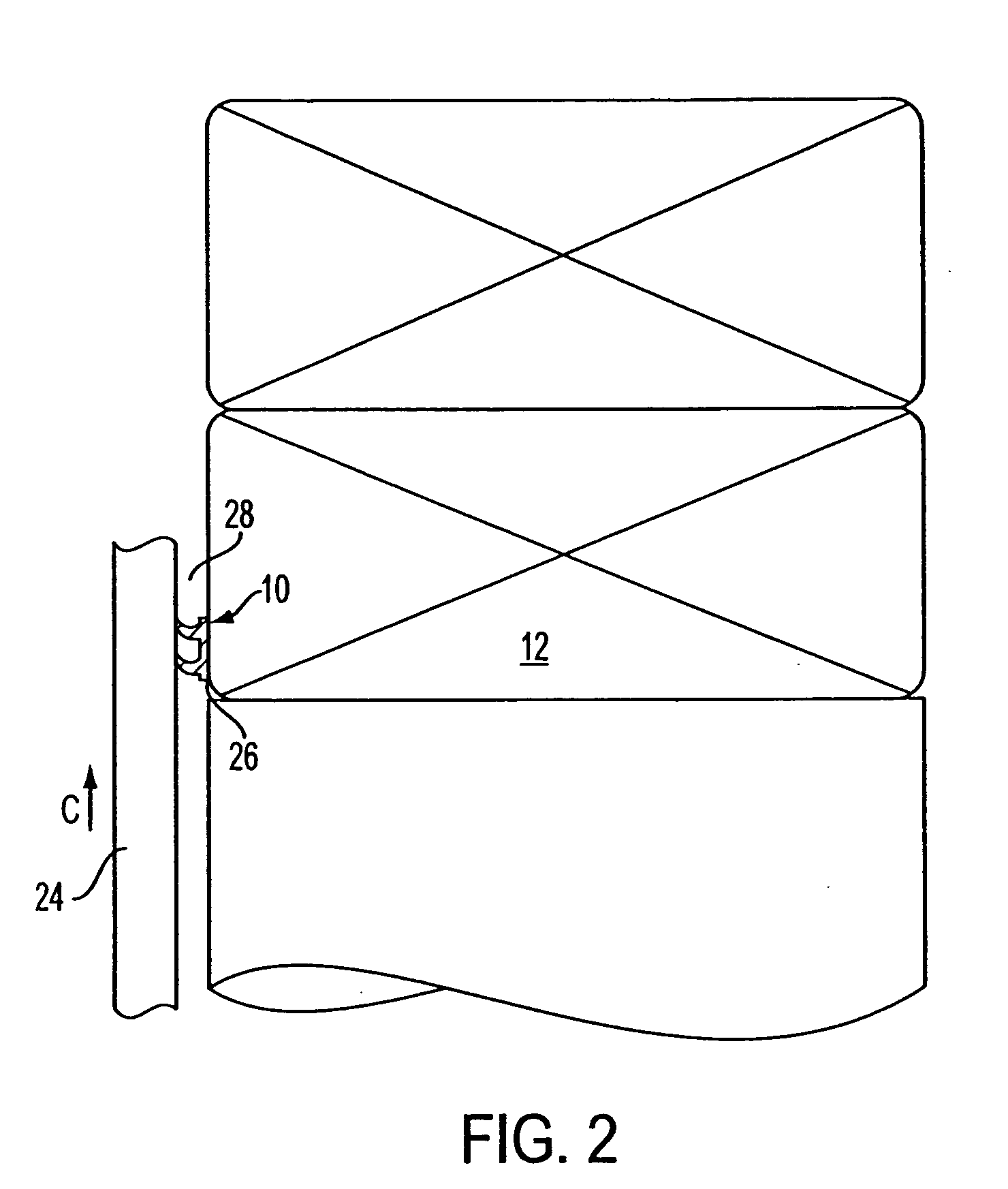

[0028] With reference to FIGS. 1 and 3, a seal structure, generally indicated at 10 and provided in accordance with the principles of the present invention, is shown coupled to a top plate or member 12 of a wall. The seal structure 10 is comprised of curable, flowable, non-sag material such as silicone caulk so as to be easily applied, for example, with conventional caulking equipment. The material of the seal structure 10 is preferably a silicone glazing adhesive / sealant which holds it shape without sagging when tooled. The material preferably has a neutral cure with no strong ammonia odor. Neutral cure silicones have an added advantage in that they cure due to atmospheric moisture, and therefore cure rapidly in virtually all temperature ranges experienced at a construction site. A preferred material has a medium modulus, which gives the material approximately 50% or more joint movement capability, exhibits a “skin” in about 5 to about 10 minutes after application, and achieves a f...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap