Trigger guard on firearm

a technology for firearms and trigger guards, applied in the field of trigger guards, can solve the problems of unsuitable known trigger guards, unusable inadvertent trigger actuation, and more susceptible to unintended trigger actuation, and achieve the effect of reducing abrasive conta

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

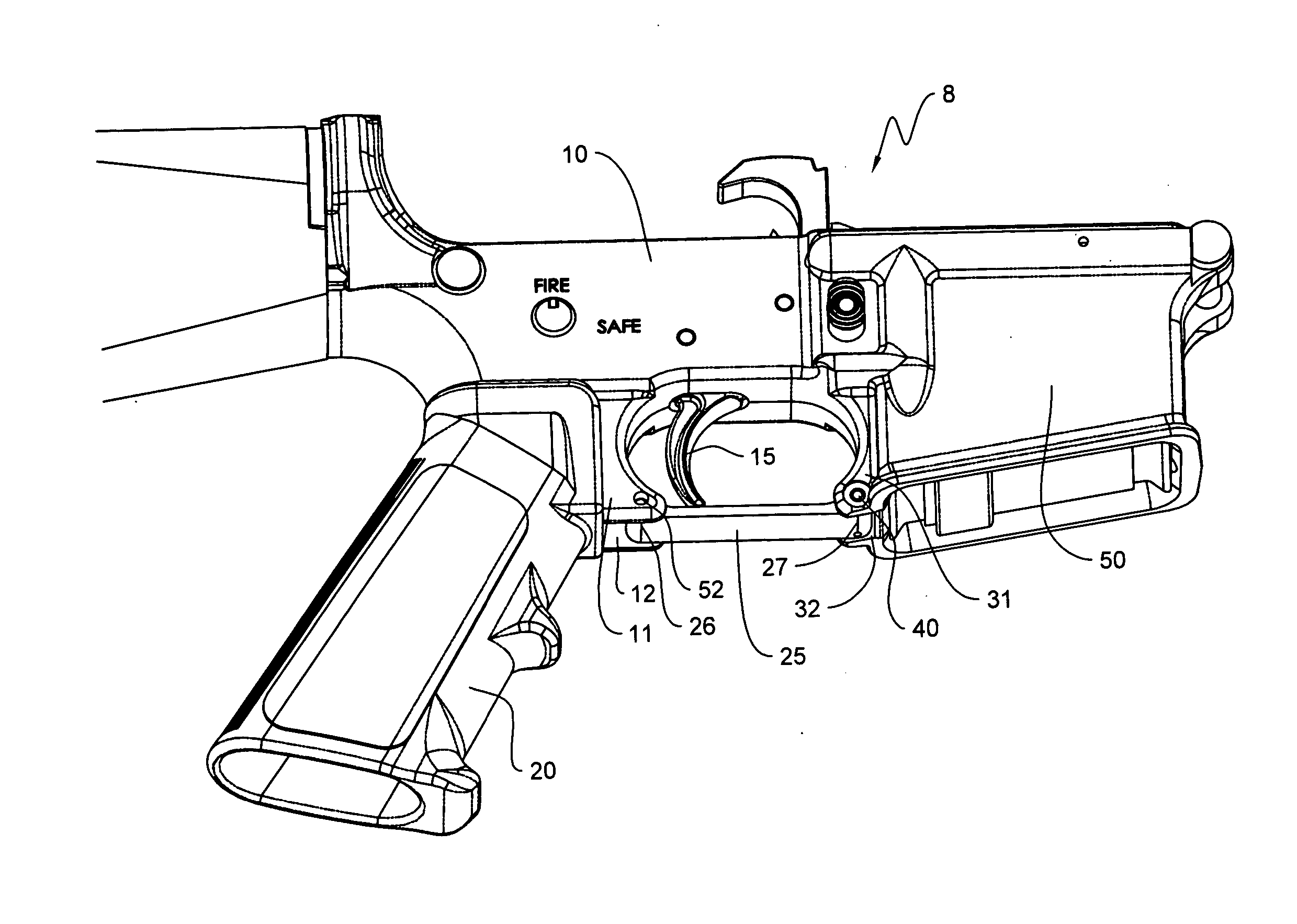

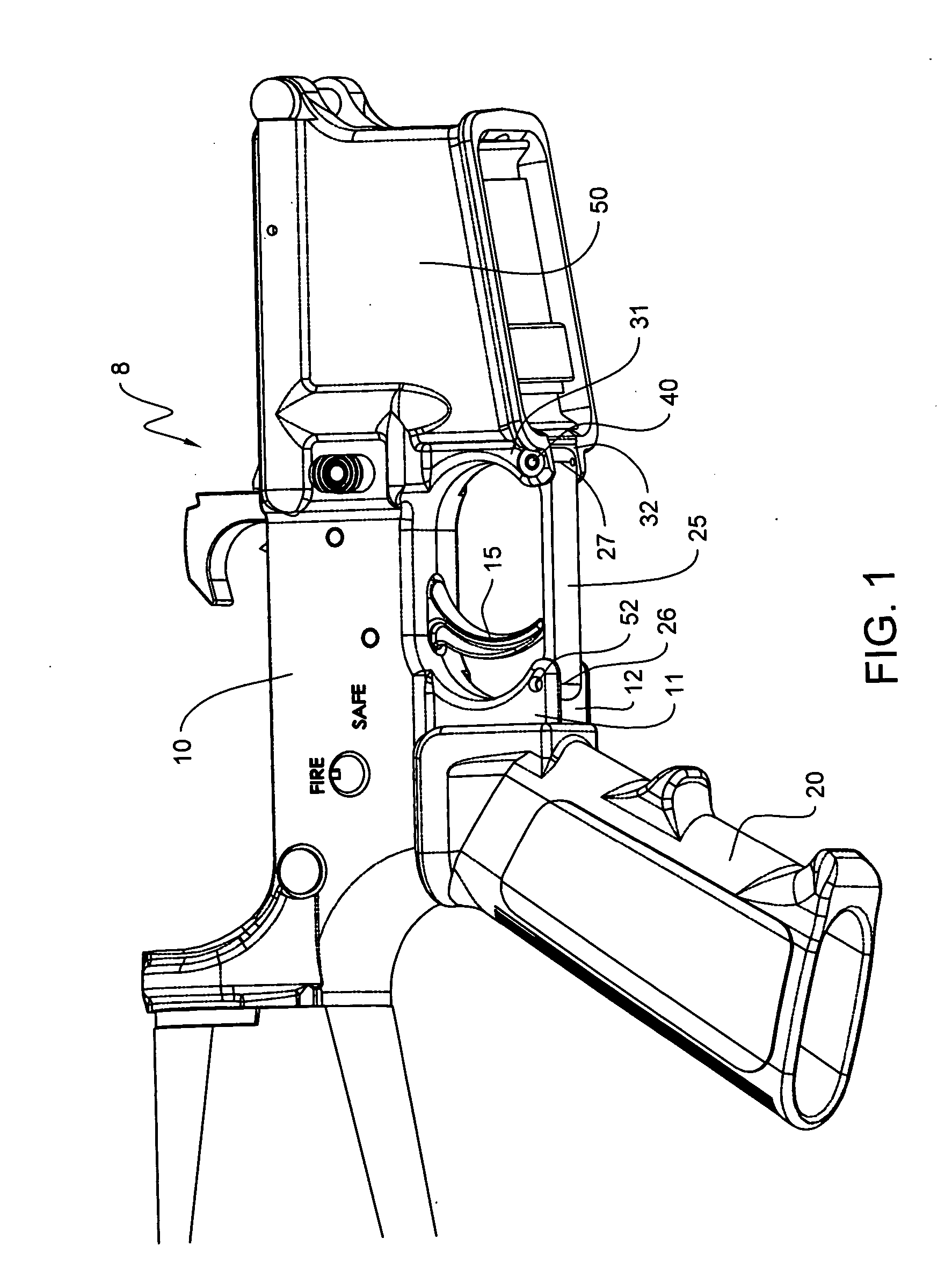

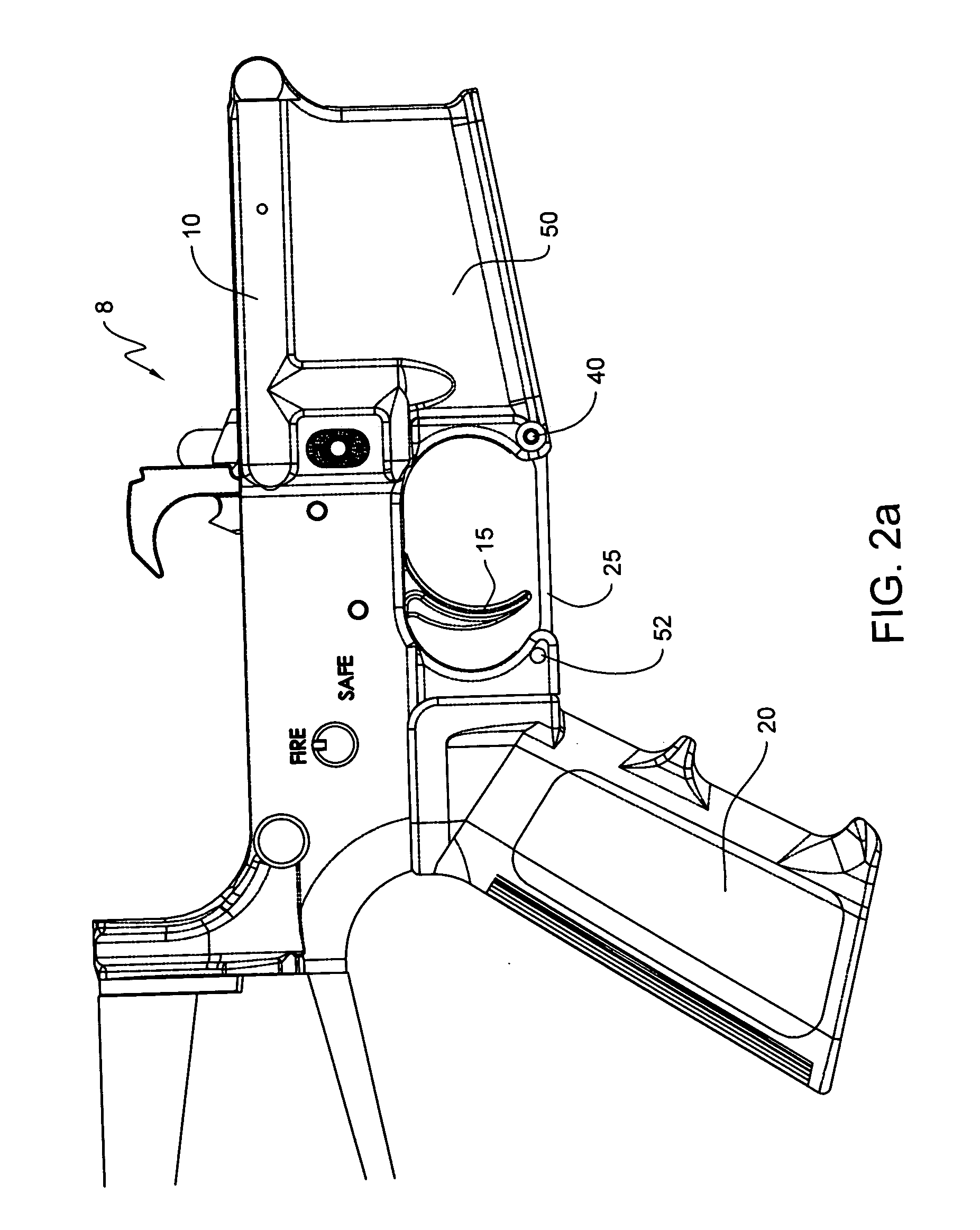

[0026]FIGS. 1-3b depict the prior art trigger guard. FIG. 1 illustrates a partial isometric view of a firearm 8 and depicts how a receiver 10 supports an arm 11 and an arm 12, both of which extend downwardly from the receiver and between a trigger 15 and a grip 20. A trigger guard 25 is shown with a first end 26 rotatably mounted to the arms 11 and 12. A second end 27 is mounted to an arm 31 and an arm 32. The arms 31 and 32 extend downwardly from the receiver 10 and between the magazine well 50 and the trigger 15. The magazine well is the portion of the receiver configured to accept a magazine. The first end 26 of the trigger guard 25 is retained by a pin 52 and the second end 27 is retained by a detent 40. The arms 11, 12, 31, 32 and trigger guard 25 form an enclosure for the trigger 15 to protect the trigger from inadvertent actuation.

[0027] As can be appreciated, the profile of the first arm 11 and second arm 12 are shaped like a partial “C” facing to the right. The profile of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com