Drywall joint fixture and method

a technology of drywall joints and fixtures, applied in the direction of walls, coverings/linings, constructions, etc., can solve the problems of not being able to meet the needs of sufficient people, and achieve the effect of reducing installation costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

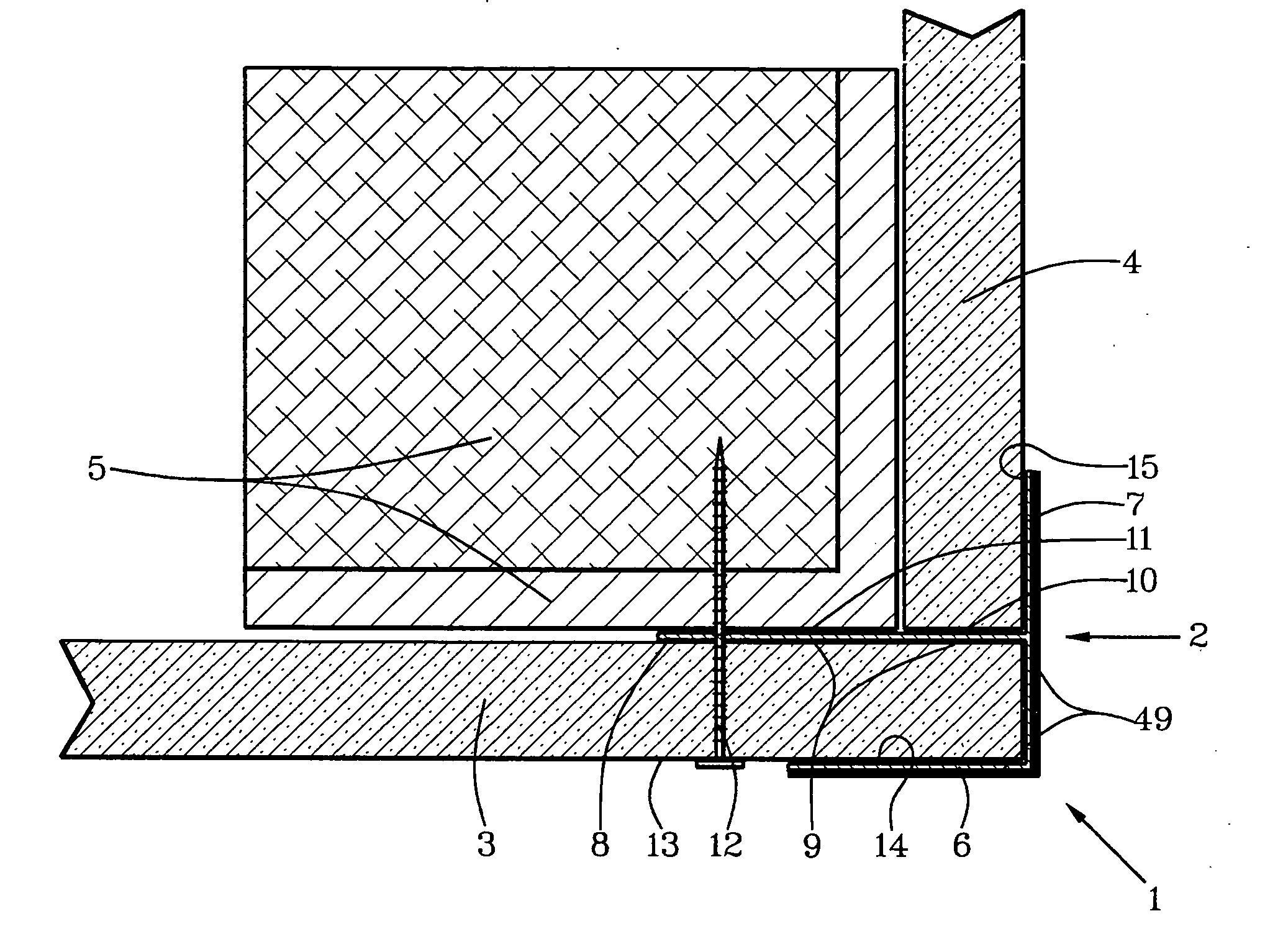

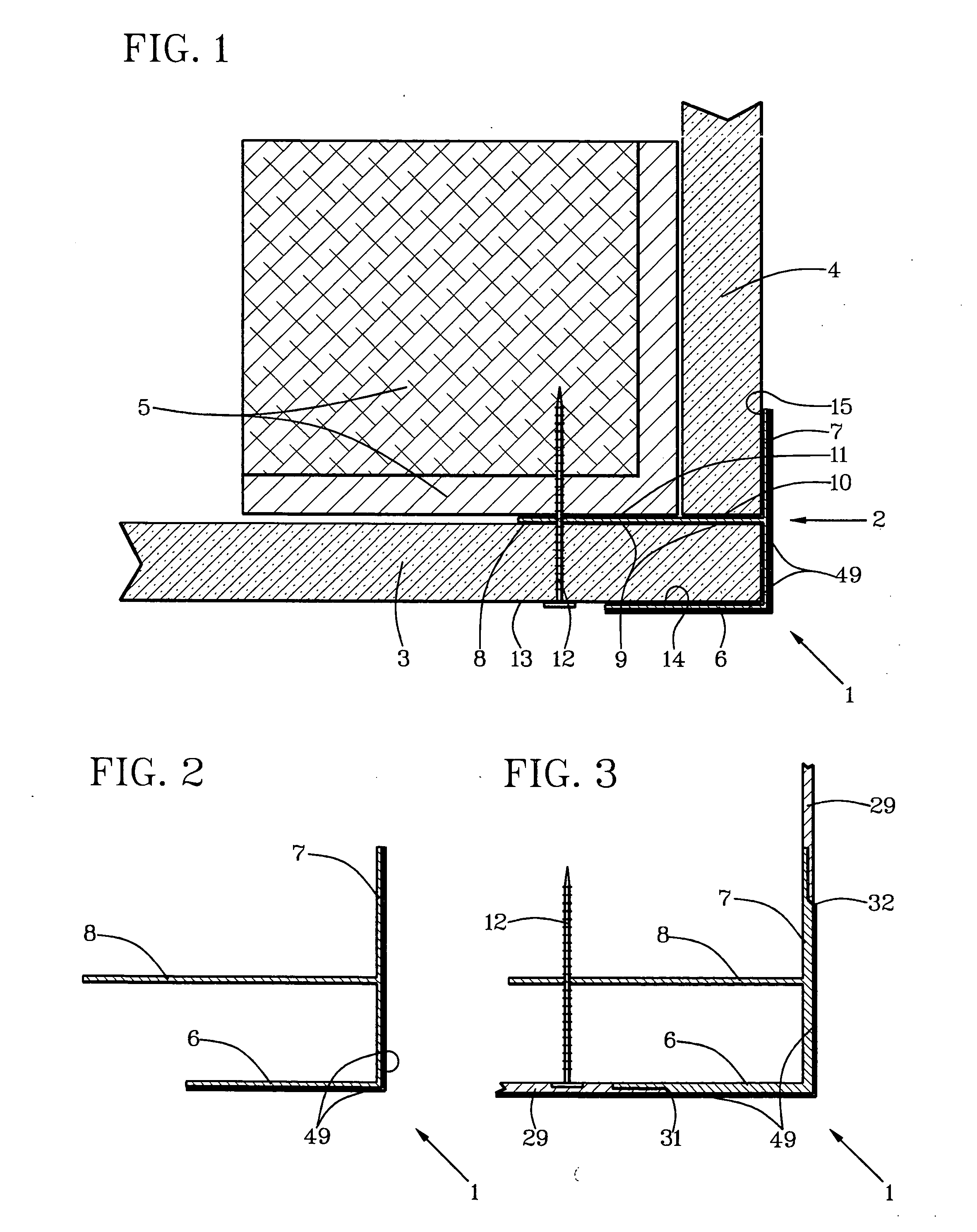

[0040] Listed numerically below with reference to the drawings are terms used to describe features of this invention. These terms and numbers assigned to them designate the same features throughout this description. [0041]1. Drywall-joint cover [0042]2. Drywall joint [0043]3. First sheet [0044]4. Second sheet [0045]5. Wall framework [0046]6. First side [0047]7. Second side [0048]8. Attachment flange [0049]9. First-sheet edge [0050]10. Second-sheet edge [0051]11. Framework wall [0052]12. Fastener shanks [0053]13. Fastener-edge area [0054]14. First-edge area [0055]15. Second-edge area [0056]16. Net material [0057]17. Mud apertures [0058]18. Fiberglass sheeting [0059]19. L-leg second side [0060]20. Wall-end second side [0061]21. Bull-nose arcuate corner [0062]22. Vacant space [0063]23. Arcuate drywall edges [0064]24. Concave corner [0065]25. Inside-wall edge [0066]26. Wall-end second side [0067]27. First drywall-joint cover [0068]28. Second drywall-joint cover [0069]29. Wall-finishing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com