Self-propelled cleaner and suspension mechanism

a self-propelled cleaner and suspension mechanism technology, which is applied in the direction of suction cleaners, construction, applications, etc., can solve the problems of reduced mechanical malfunctions attributed to manufacturing and assembly errors are easy to be generated, and the self-propelled cleaner cannot be properly implemented. , to achieve the effect of increasing the ground contact properties of drive wheels

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Embodiments of the present invention will be explained with reference to the drawings hereinafter.

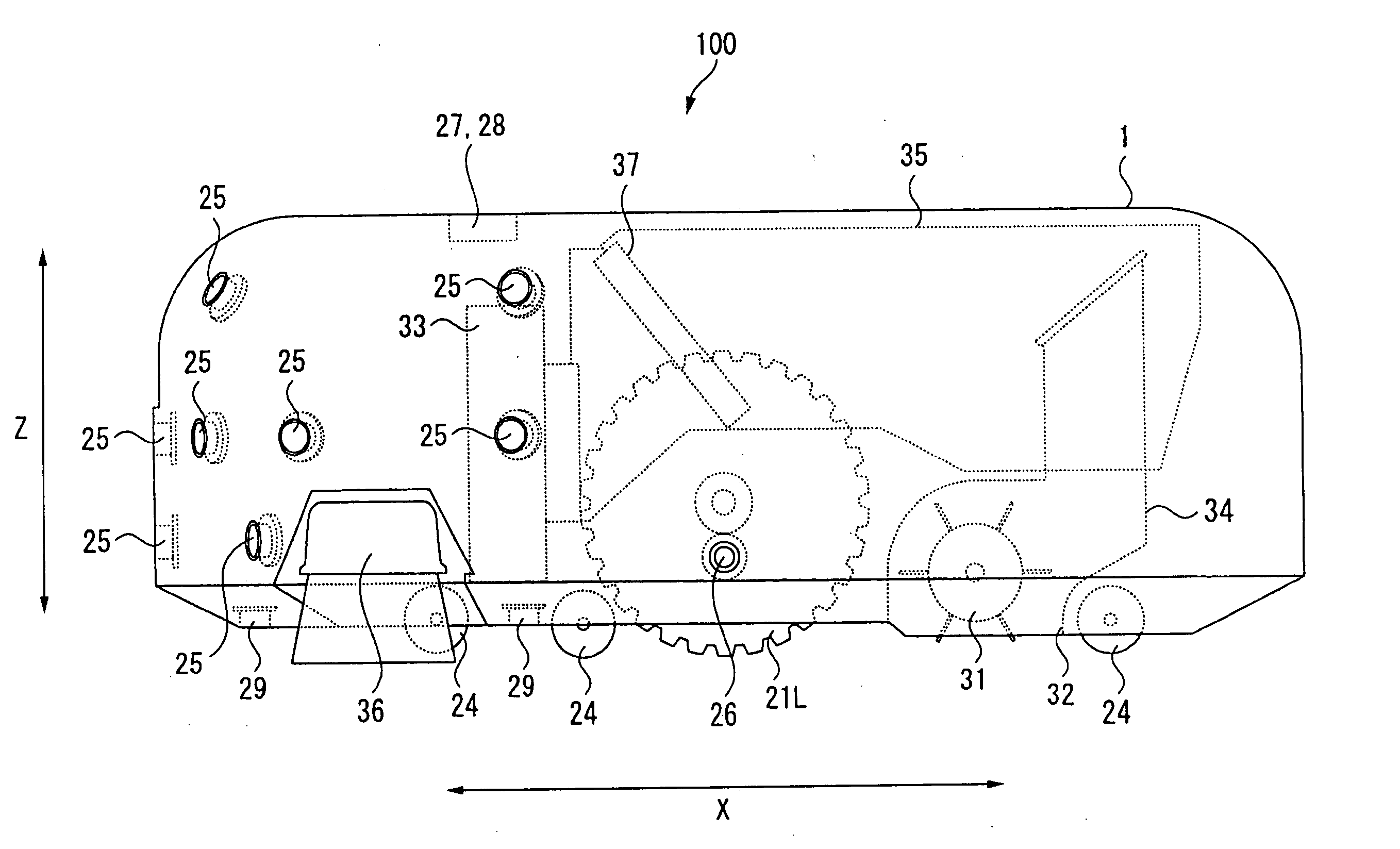

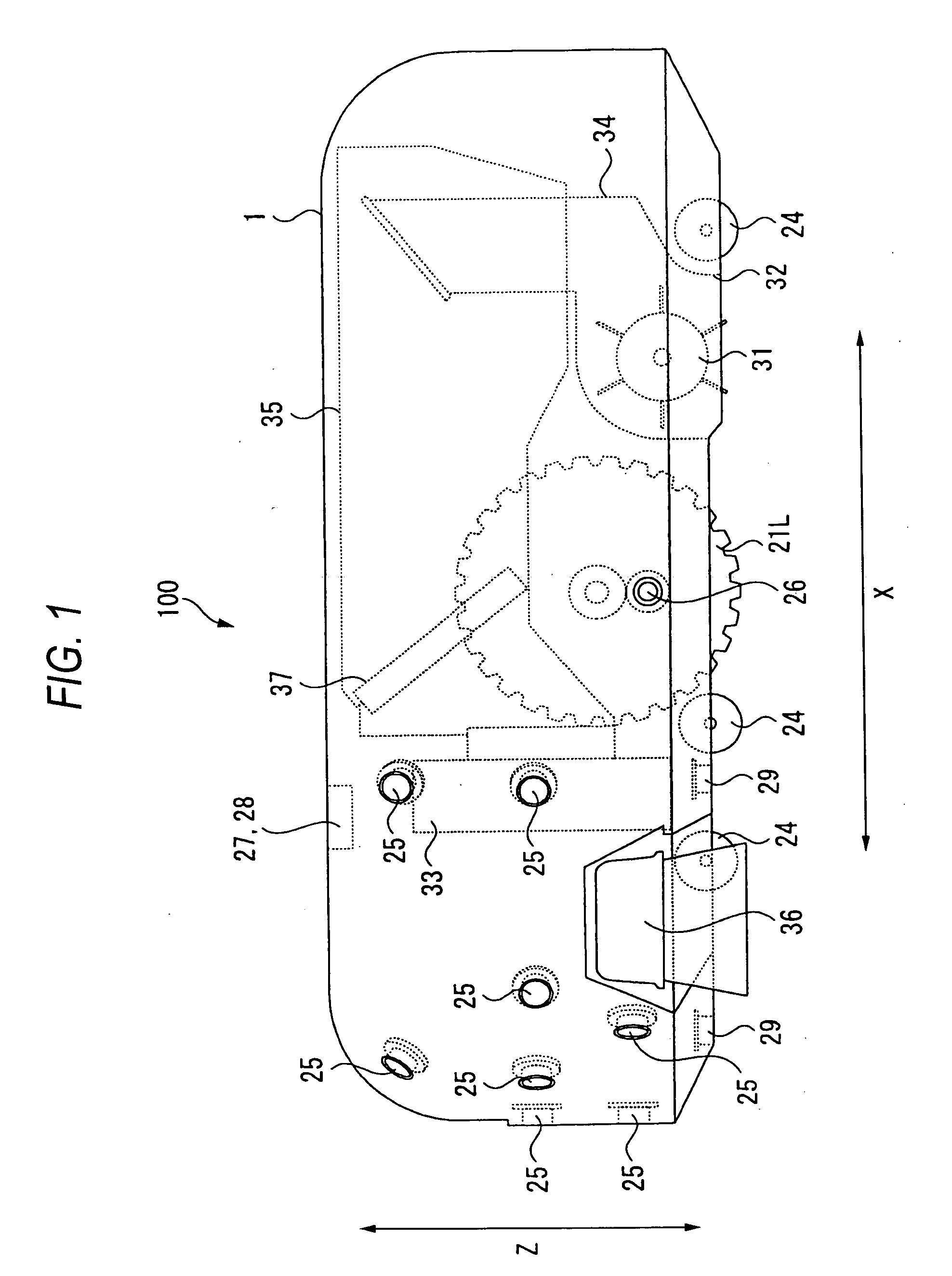

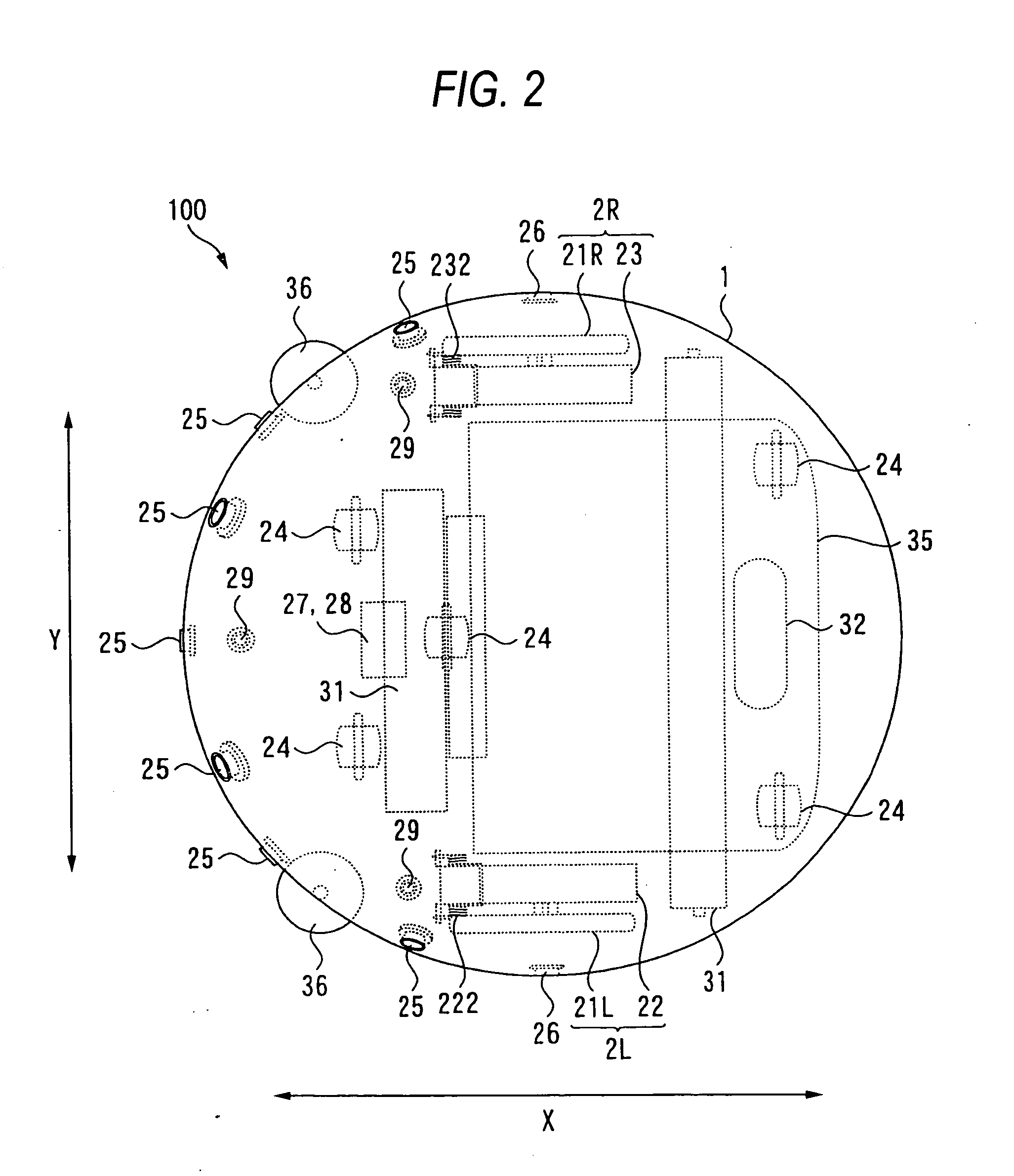

[0020]FIG. 1 is a side view of a self-propelled cleaner which will be illustrated as a preferred embodiment to which the invention is applied, resulting when the self-propelled cleaner is viewed from a side thereof, FIG. 2 is a plan view showing the self-propelled cleaner, and FIG. 3 is a front view of the self-propelled cleaner. In addition, FIG. 4 is a block diagram illustrating the configuration of a main part of the self-propelled cleaner.

[0021] Note that in FIGS. 1 to 3, states within a housing 1 of a self-propelled cleaner 100 are shown which would result when the interior of the housing were seen through the housing, and respective constituent elements provided within the housing 1 are to be shown by broken lines.

[0022] In addition, in the following description, a direction along a traveling direction of the self-propelled cleaner 100 is regarded as a longitudinal direc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com