Bottle lid

a bottle lid and lid technology, applied in the field of bottle lids, can solve the problems of inability to properly seal the bottle, the sealing device can easily get pushed upward toward the upper part of the bottle, and even become completely detached from the bottle, so as to prevent inadvertent detachment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The most preferred embodiment of the present invention will be explained in detail below referring to the attached drawings.

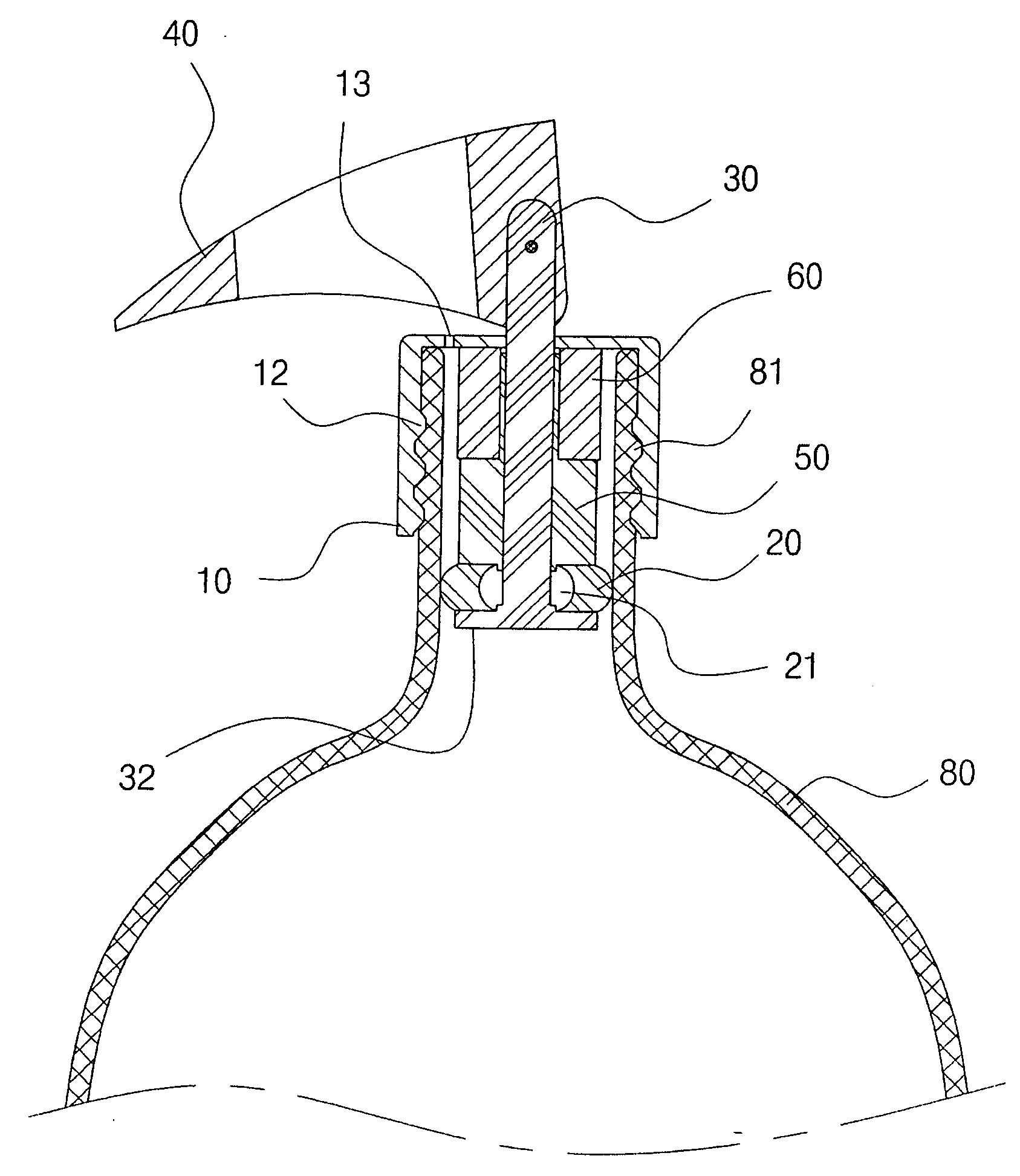

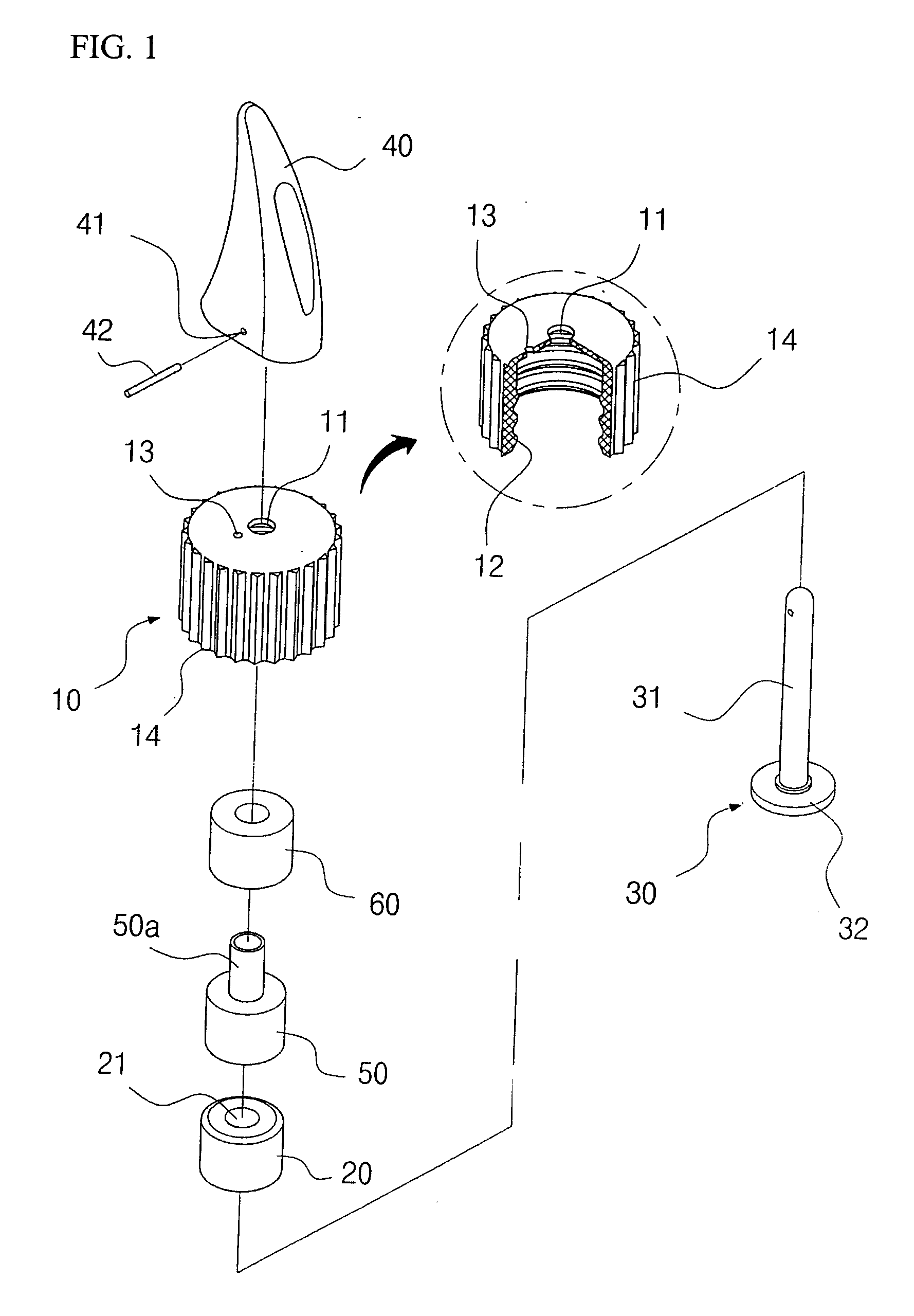

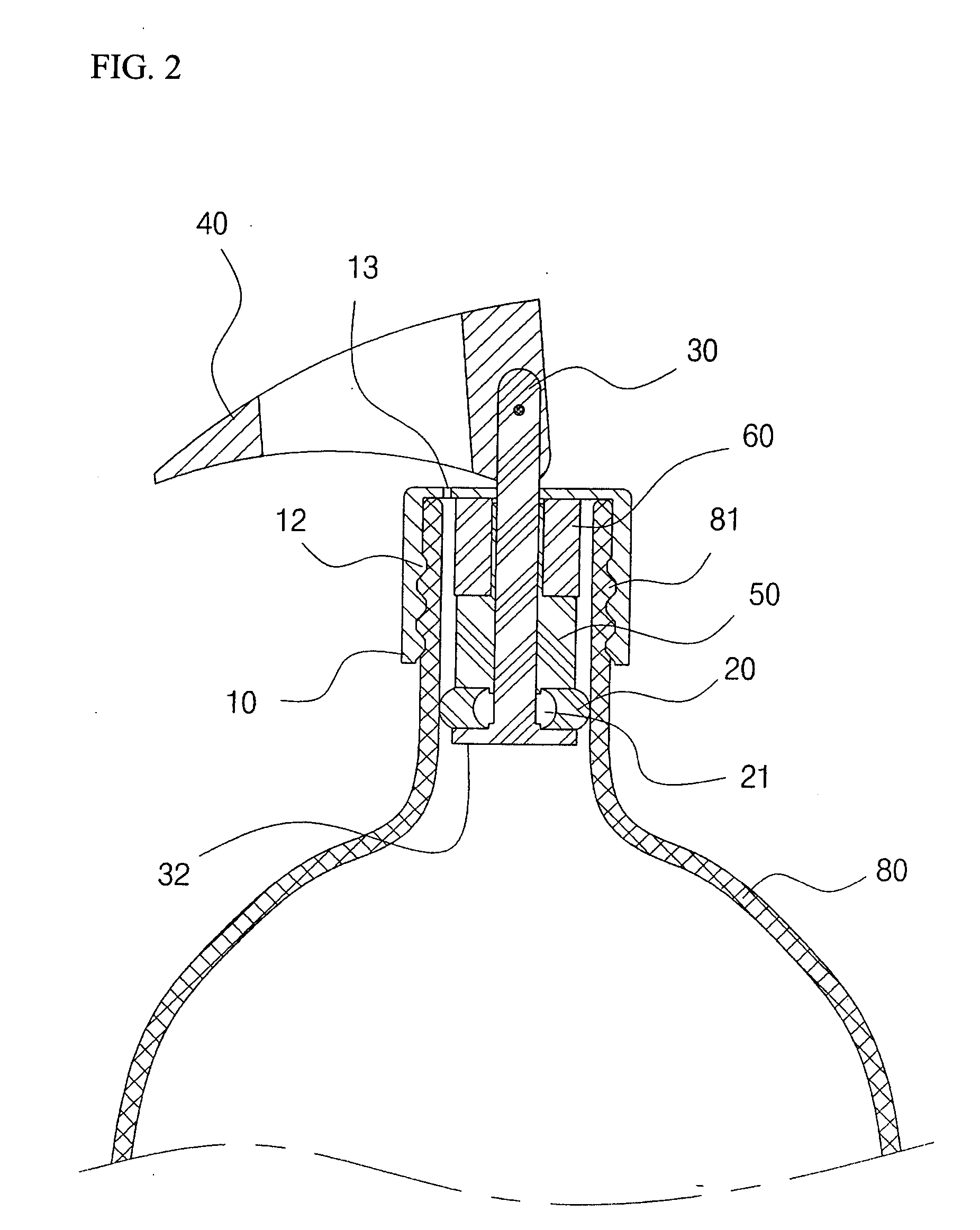

[0023] The present invention in a bottle lid and cap includes at least the following elements: a cap (10) that fits over the outside of a bottle mouth; an operating member (30) that is fitted into a passage or through hole (11) in the upper side of the cap, the operating member including a sealing element (20) placed on a support pad (32) at a lower end of the sealing element, with the support pad being integrally formed with a support post (31), and the support post being inserted through the sealing element and maintaining contact or a close equidistant spacing from the sealing element (20); an operating lever (40) at a top end of a support post (31) of the operating member (30), the operating lever (40) being attached to the top end of the support post (31) of the operating member (30) along a common vertical axis by a hinge (not shown) or by a pin (...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com