Bottle assembly with removable container assembly

a bottle and container technology, applied in the field of plastic water bottles, can solve the problems of easy misplacement of one or the other, difficulty in handling both at once,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

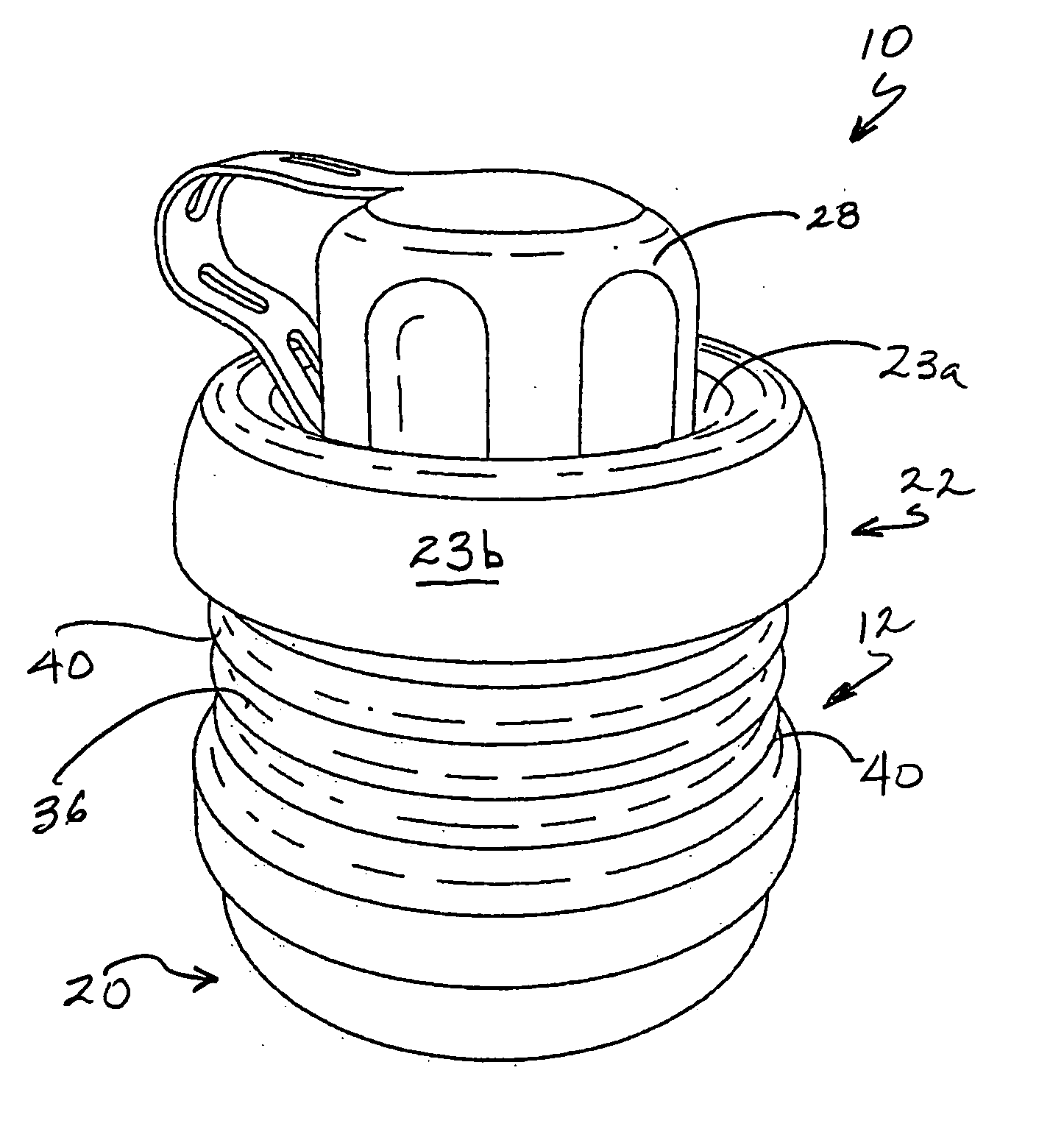

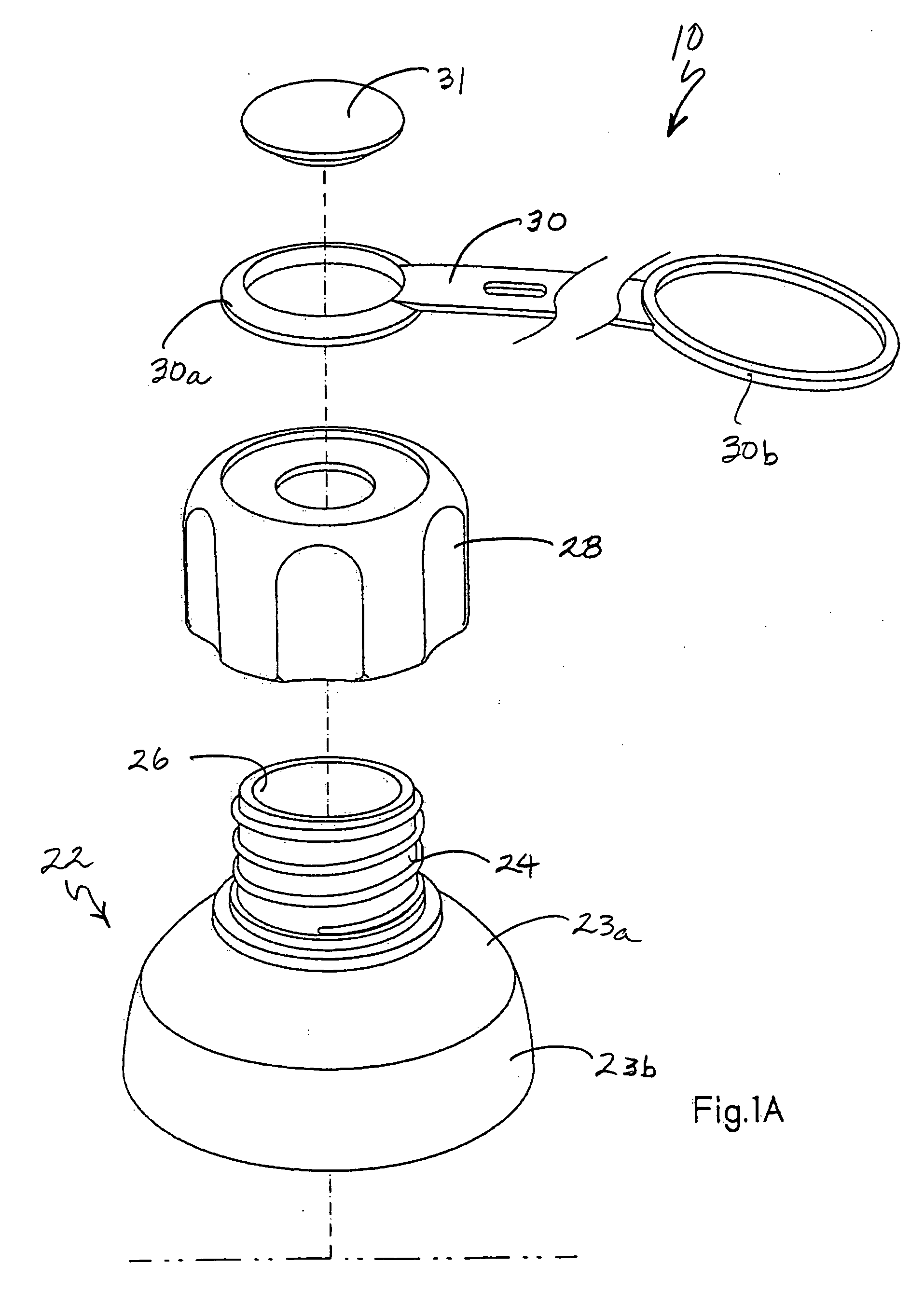

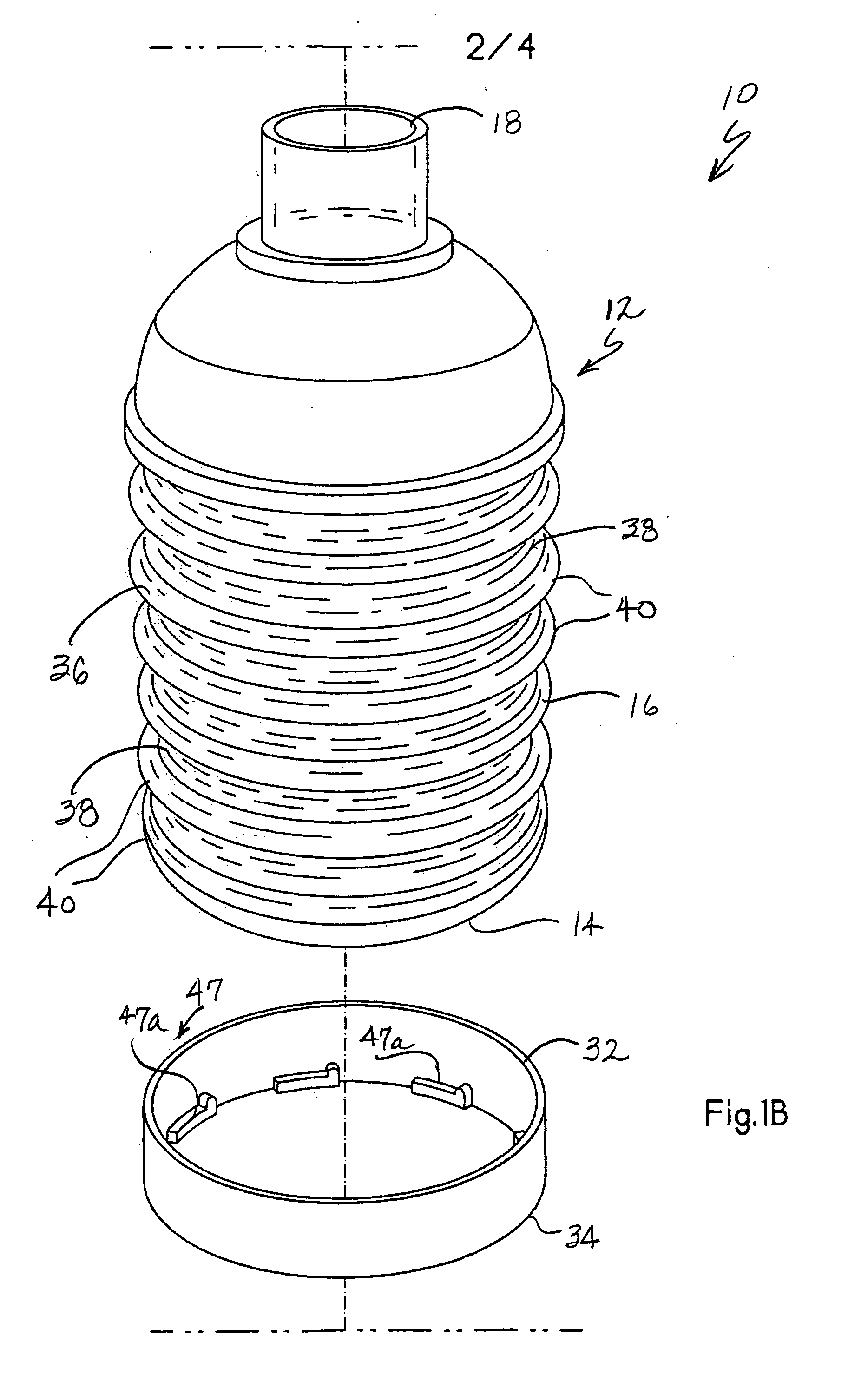

[0014] Referring now to FIGS. 1A-1C, a plastic bottle assembly is generally designated as 10. Included in the assembly 10 is a bottle generally designated 12 suitable for retaining drinking water or other beverage having a bottom 14. Extending from the bottom 14 is a generally cylindrical body 16. Opposite the bottom 14 is a top opening 18. The bottle assembly 10 further includes a multi-compartment container assembly generally designated 20 that is removably secured to a lower portion of the bottle 12. It is contemplated that the bottle 12 is manufactured from a durable and flexible thermoplastic, although it is contemplated that other materials may be used, as are known in the art. Many suitable techniques for making the bottle 12 are contemplated, including but not limited to blow molding or injection molding. It is further contemplated that the multi-compartment container assembly 20 is manufactured from a rigid thermoplastic that will retain its shape, as is known by those skil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com