Optical inspection system for reconstructing three-dimensional images of coins and for sorting coins

a three-dimensional image and inspection system technology, applied in coin testing, coin/paper handlers, instruments, etc., can solve the problem that the inspection system cannot distinguish between real coins and counterfeit coins

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

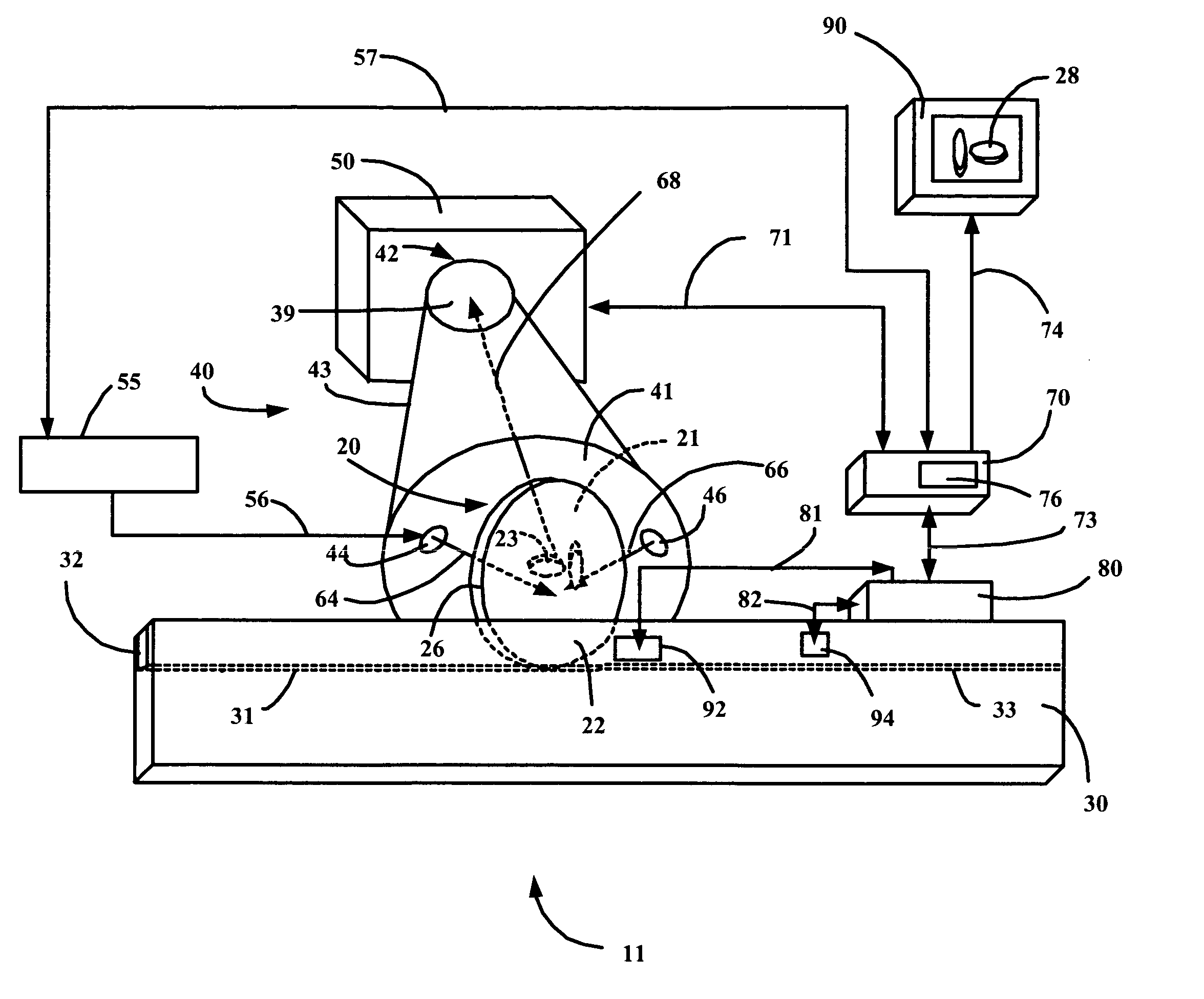

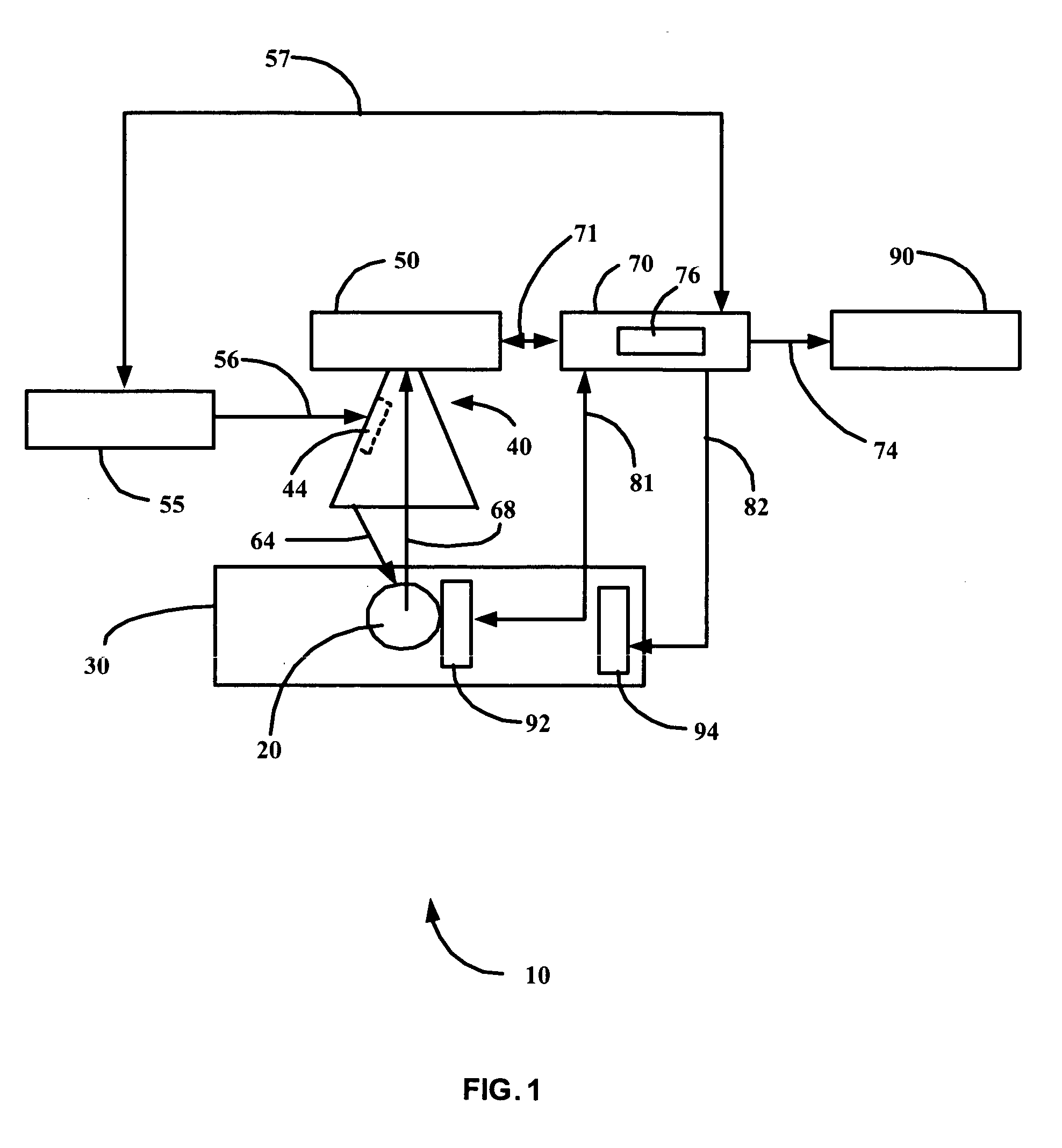

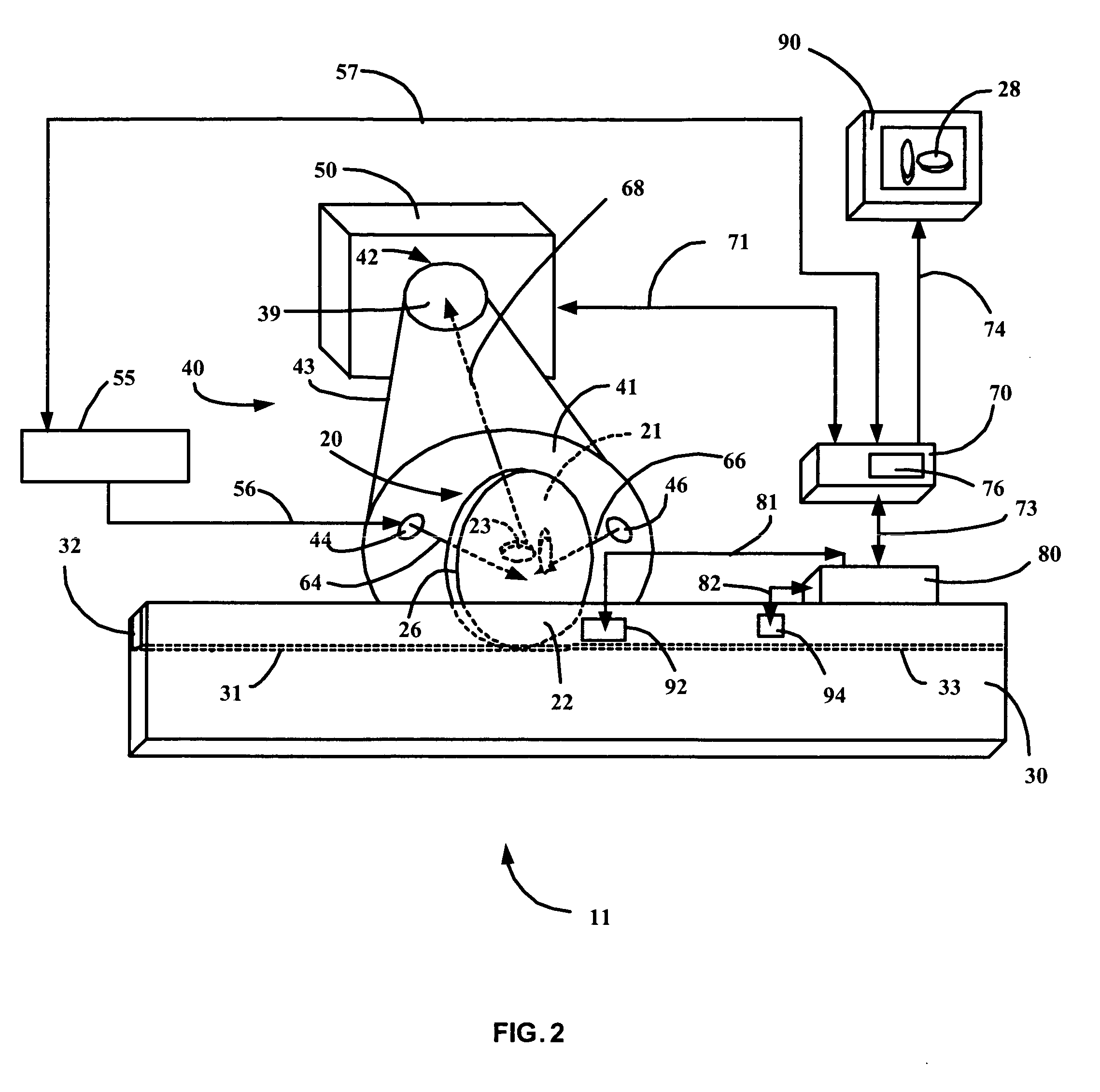

[0025]FIGS. 2-5 show the coin inspection system 11 with coin sorting capability. FIG. 2 shows an oblique view of a coin inspection system 11 capable of rendering a three-dimensional image 28 of at least a portion of surface 21 of the coin 20. The coin inspection system 11 is additionally capable of sorting coins 20 based on a determined value. FIG. 3 shows a side view of the coin inspection system 11. FIG. 4 shows a top view of the coin inspection system 11 operable to sort a coin 20 to a channel 33B. FIG. 5 shows a top view of the coin inspection system 11 operable to sort a coin 20 to a channel 33A.

[0026] The coin 20 has a front surface 21, a back surface 22 and an edge 26. The front surface 21 has three-dimensional markings 23 and back surface 22 has three-dimensional markings 24 as shown in FIG. 3. FIG. 5 shows an alternative set of three-dimensional markings 25 for a different coin 20.

[0027] In one embodiment, the coin passageway 30 is a conveyer system operable to position th...

second embodiment

[0076]FIG. 7, in which like elements share like reference numbers with FIG. 3, shows a schematic cross sectional view of a coin inspection system 12 according to the invention. The coin inspection system 12 examines the two faces of the coin 20 simultaneously. Coin inspection system 12 is required for coins that have a non-unique side. Coin inspection system 12 examines both sides of the coin 20 to ensure an examination of the coin's unique side. In coin inspection system 12, illumination apparatus 40 illuminates surface 21 of coin 20 while illumination apparatus 140 illuminates surface 22 of coin 20.

[0077] The coin passageway 130 is a conveyer system operable to position the surface 21 in front of the illumination apparatus 40 and surface 22 in front of illumination apparatus 140. The coin passageway 130 includes the coin passageway 30, releasable stop 92 and guiding mechanism 94 which have the same configuration and operation as described in FIGS. 2-5.

[0078] The illumination appa...

third embodiment

[0086]FIG. 8, in which like elements share like reference numbers with FIGS. 1 and 2, is a block diagram of a coin inspection system 13 according to the invention. The coin inspection system 13 has the capability to examine more than one coin at once.

[0087] Coin inspection system 13 includes a coin passageway 230, illumination apparatus 40 and illumination apparatus 240, sensing apparatus 50 and a sensing apparatus 250 and processing apparatus 270. The illumination apparatus 240 illuminates at least one coin 220 positioned on, in or within coin passageway 230 with light 264 while illumination apparatus 40 illuminates at least one coin 20 positioned on, in or within coin passageway 30 with light 64. Surface 221 of coin 220 has three-dimensional markings 223.

[0088] The structure, function and method of operating illumination apparatus 240 is similar to the illumination apparatus 40 described in FIGS. 2-5 as is understandable to those of ordinary skill in the art.

[0089] A light contr...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap