Screed heating arrangement

a heating arrangement and screed technology, applied in the direction of roads, roads, roads, etc., can solve the problems of excessive drag, buildup of paving material, and poor working environment for paving workers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

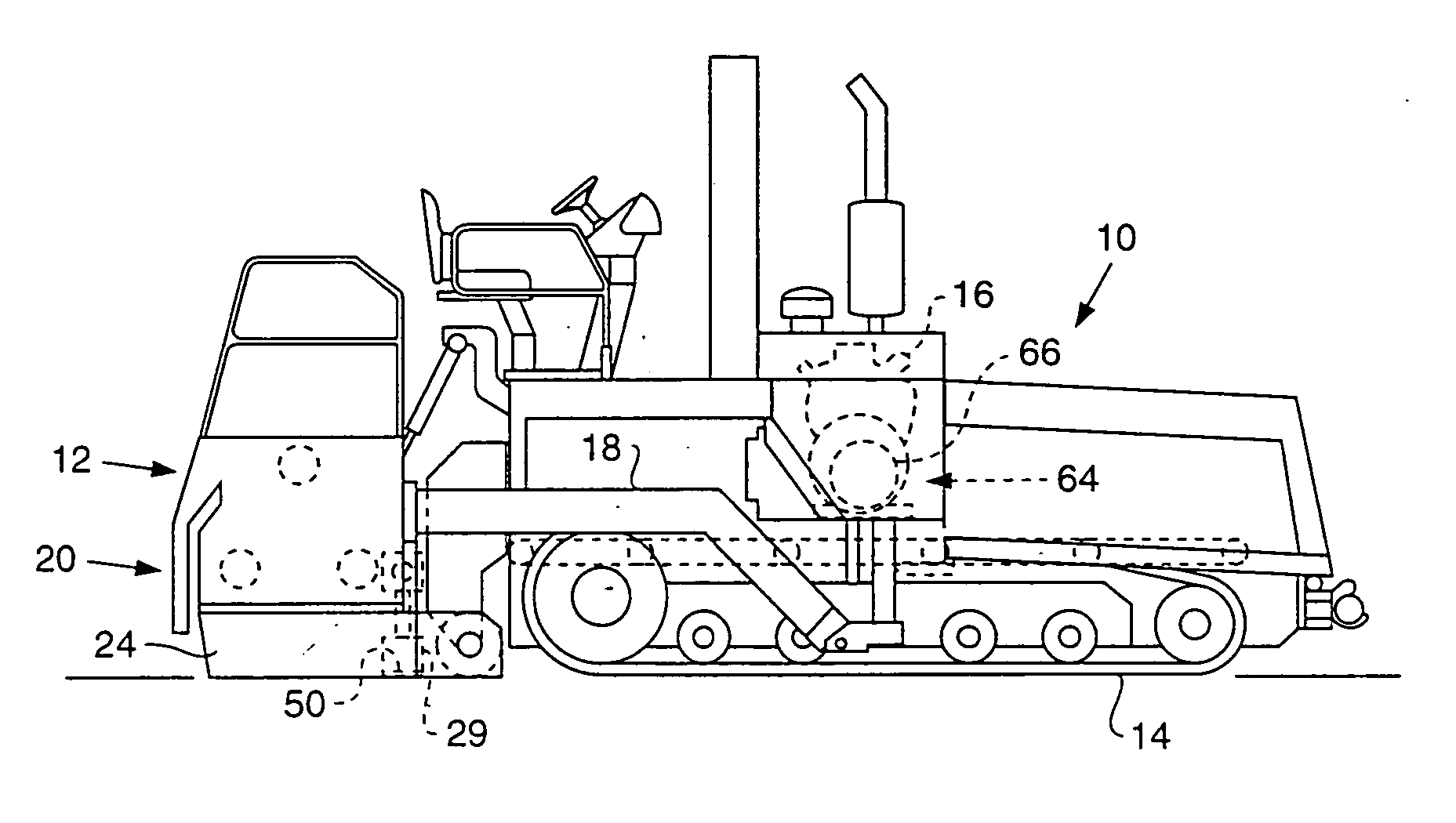

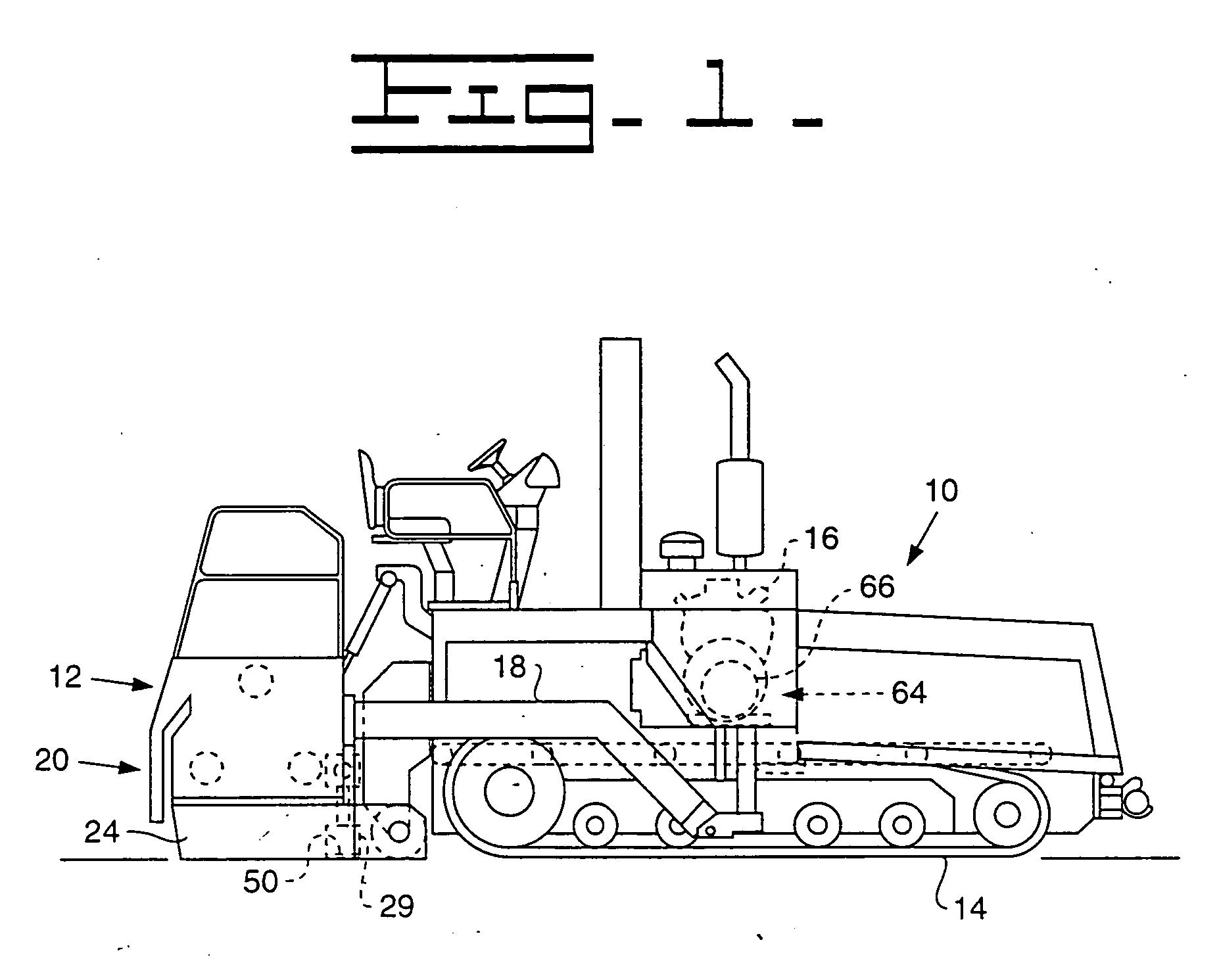

[0014] Referring to the drawings, specifically FIG. 1, an asphalt paving machine 10 is shown with a screed assembly 12 attached to the back thereof. The asphalt paving machine 10 is supported by a propelling arrangement 14 that is driven by an engine 16 in a conventional manner.

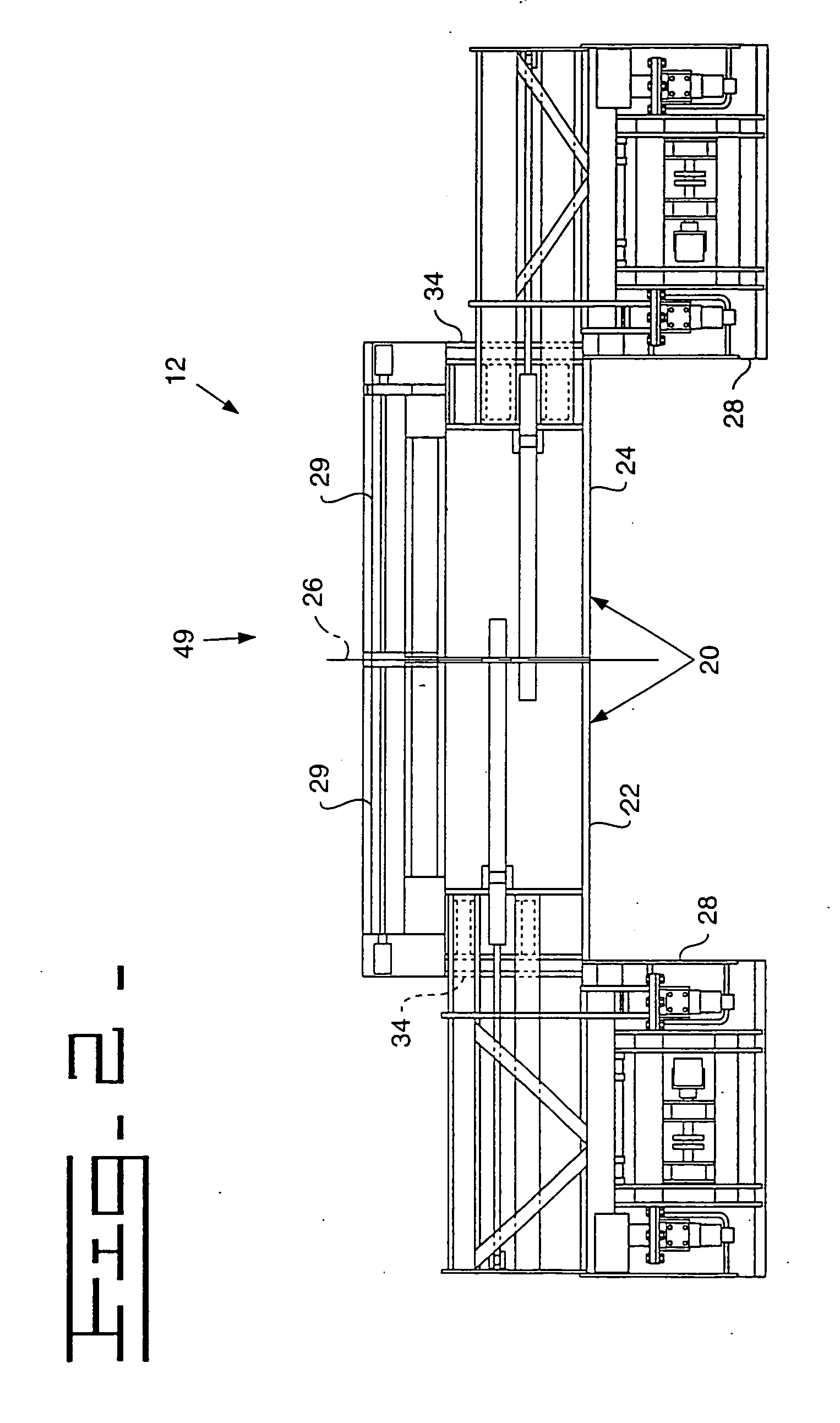

[0015] The screed assembly 12 is pivotally connected behind the asphalt paving machine 10 by tow arms 18. The screed assembly 12 may be any of a number of configurations such as a fixed width screed or a multiple section screed that includes extensions. As shown in FIG. 2, the screed assembly 12 is provided with a main screed section 20 with a left and a right screed section 22, 24. The left and right screed sections 22, 24 are hingably connected to one another along a longitudinal centerline 26 so that various operations, such as crowning, can be performed. A screed extension 28 is also provided behind and adjacent to both the left and right screed sections 22, 24. It should also be understood that screed e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com