Lid with bistably valved drinking spout

a valved drinking spout and lid technology, applied in the field of drinking containers, can solve the problems of unsanitary, messy, time-consuming, and unsanitary solution, and achieve the effect of convenient drinking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

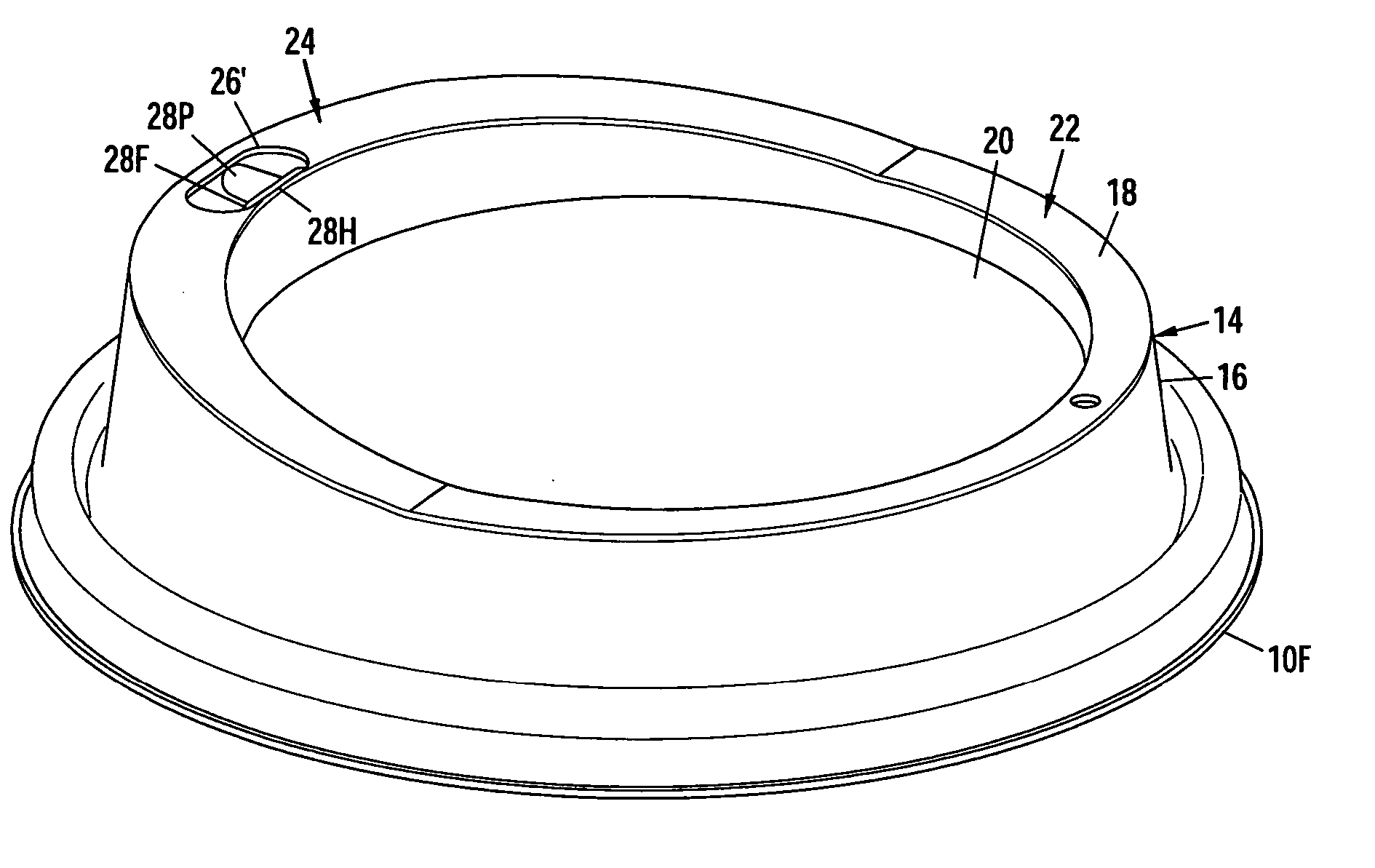

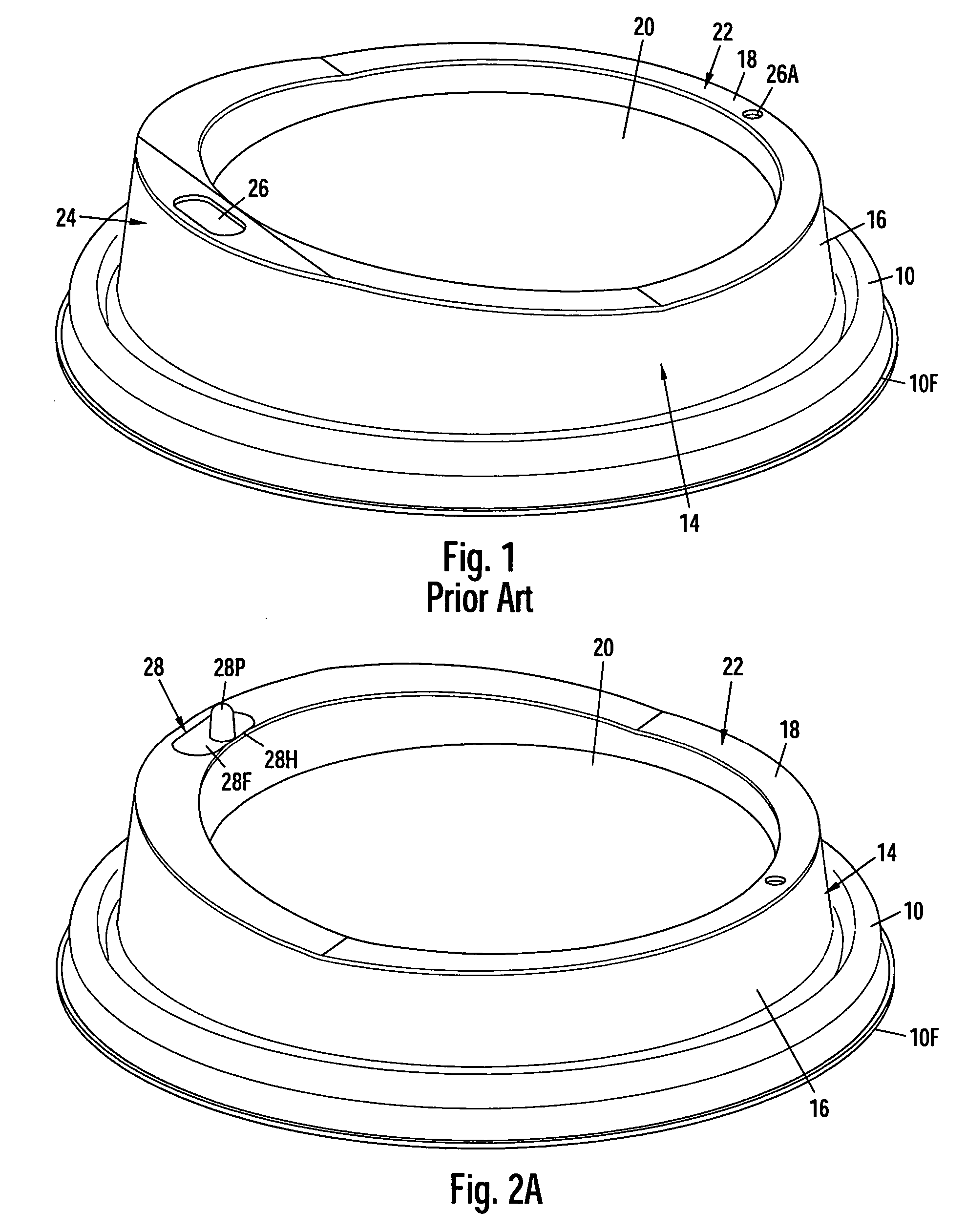

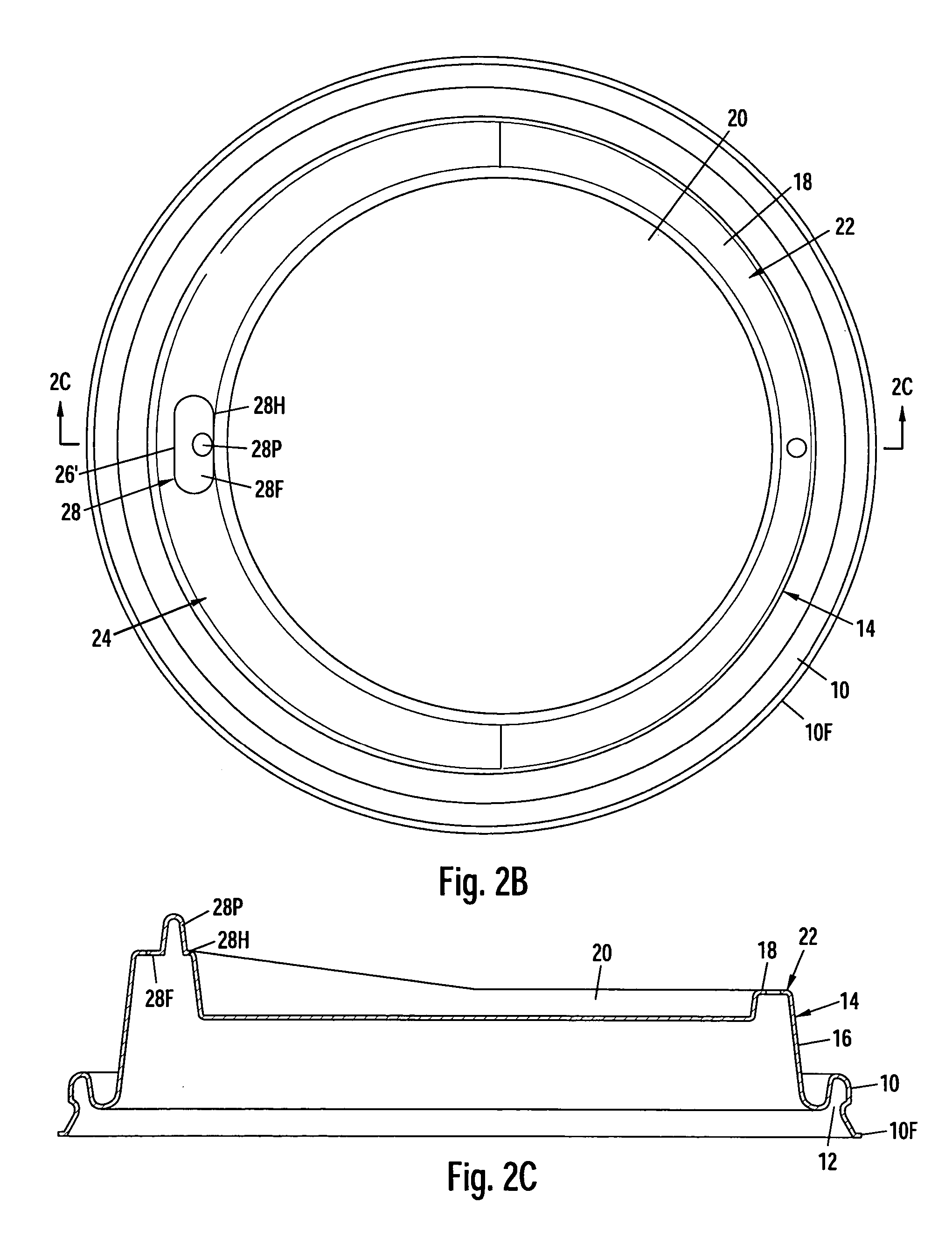

—FIG. 1—PRIOR-ART LID

[0054]FIG. 1 shows a perspective view of a prior-art drink-through domed cup lid similar to the lid shown in the Sadlier et al. design patent, supra. This lid has an annular, bottom rim 10 which has a slight flange 10F extending out from its bottom. The underside of rim 10 forms a downwardly facing annular cup-rim-gripping and sealing groove 12 (best seen in FIG. 2C). A turret or domed portion 14 extends up from inside of groove 12; turret 14 has a truncated conical shape and has an annular vertical wall 16. Turret 14 has an annular top horizontal surface, or ridge 18 that extends in from the top of wall 16, and a recess 20 that is surrounded and below ridge 18. Thus wall 16, ridge 18, and recess 20 form an annular upper rim 22. Stated differently, rim 22 is the top portion of turret 14 and encircles and defines recess 20. The front half of rim 22 slopes upwardly and then levels off to form a raised or higher and wider drinking portion or spout 24 at the front. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com