Portable air compressor tool carrier

a tool carrier and air compressor technology, applied in the direction of positive displacement liquid engines, piston pumps, liquid fuel engines, etc., can solve the problems of laborious and laborious, cumbersome transportation of air compressor components and other materials necessary to perform a particular job, and loss of work tim

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Reference will now be made in detail to the presently preferred embodiments of the invention, examples of which are illustrated in the accompanying drawings.

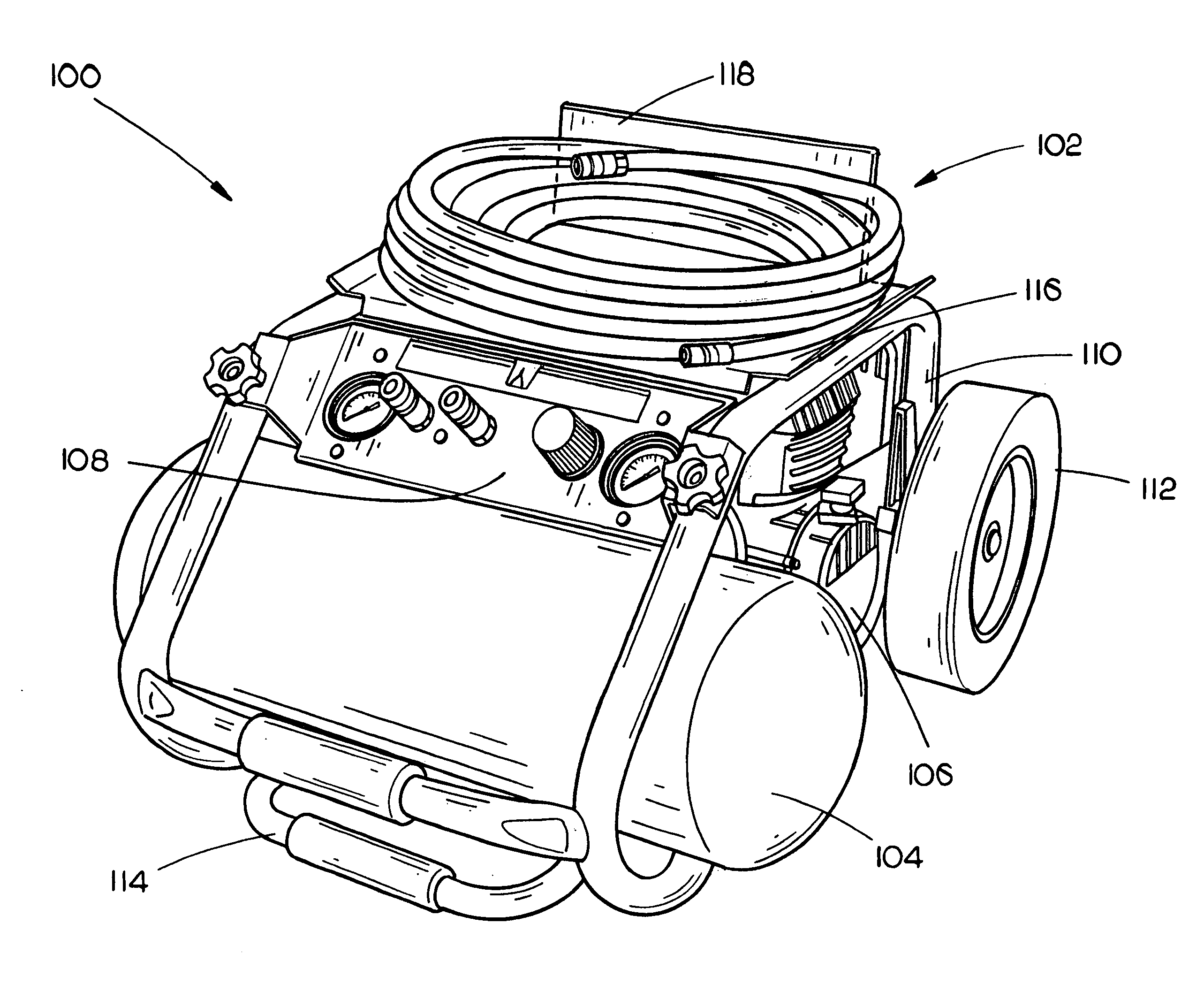

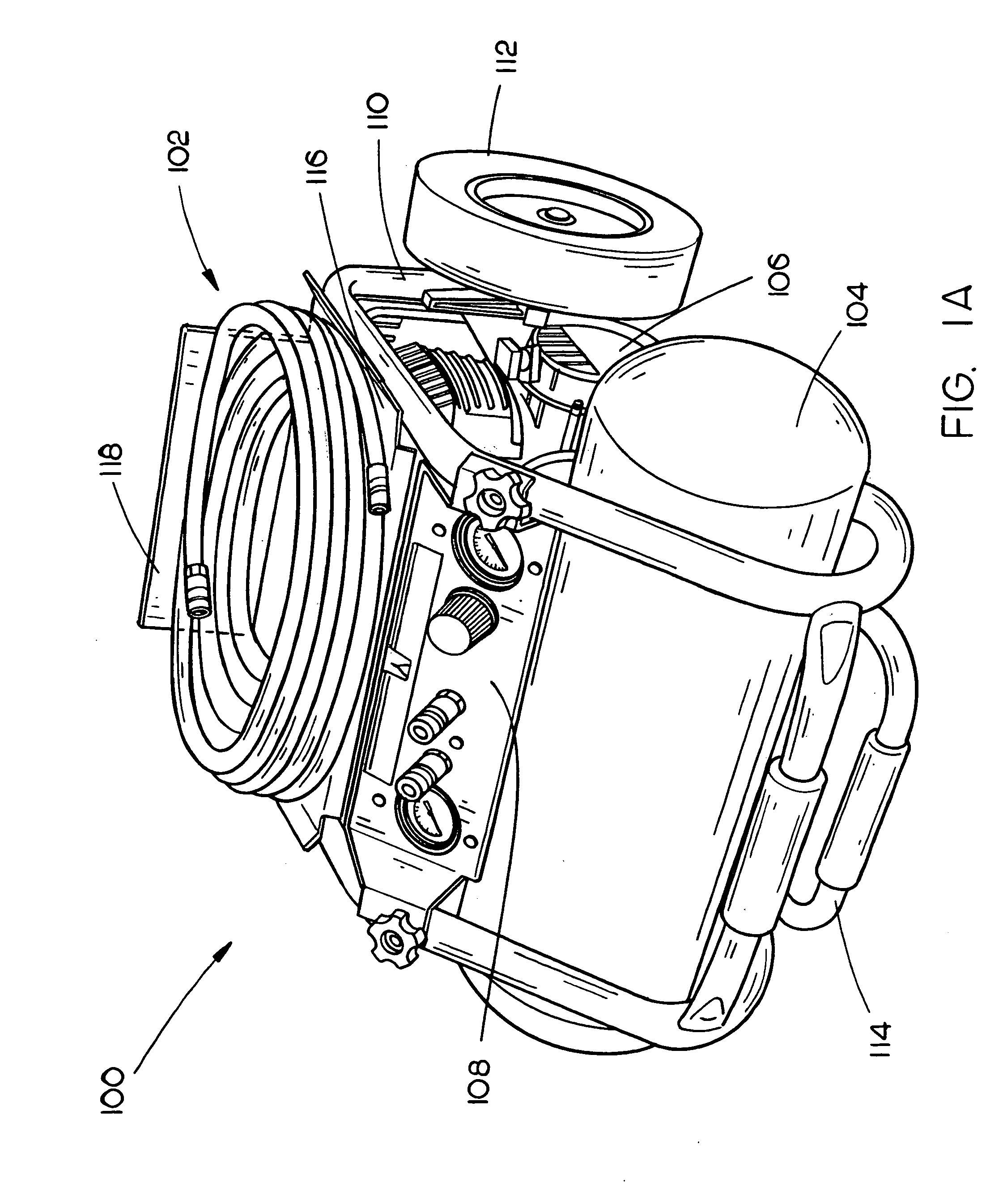

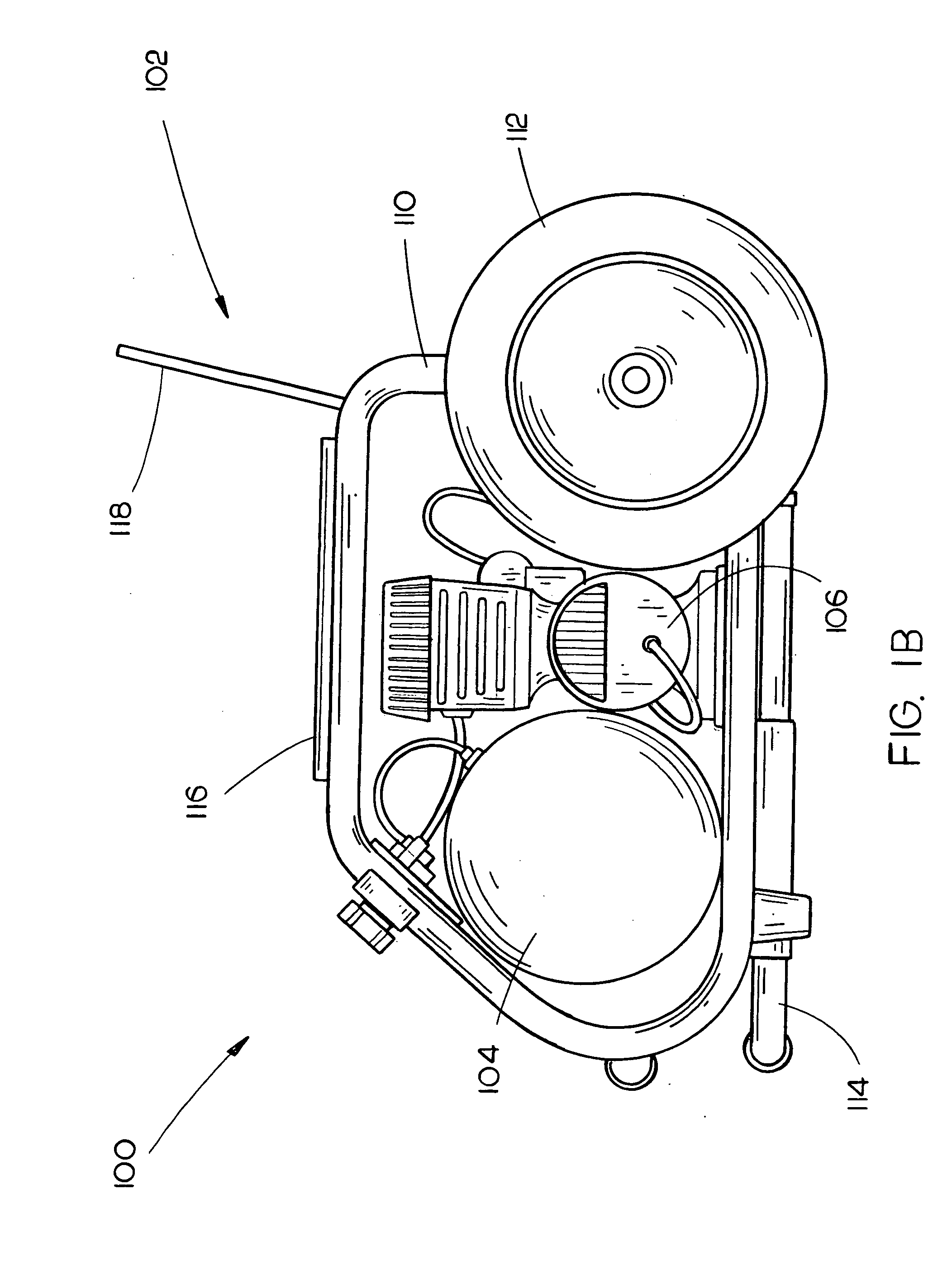

[0017] Referring specifically to FIGS. 1A and 1B, an air compressor assembly 100 including a tool carrier 102 in accordance with an exemplary embodiment of the present invention is shown. The air compressor assembly 100 includes an air storage tank 104 for storing compressed air, an air compressor 106 for supplying compressed air to the air storage tank 104, and a manifold assembly 108 for controlling and distributing compressed air from the air compressor assembly 100 to one or more air-powered tools. In exemplary embodiments, the manifold assembly 108 may be removable.

[0018] As shown in FIGS. 1A and 1B, the air compressor assembly 100 is equipped with a frame or roll cage 110 that at least substantially surrounds the air storage tank 104 and the air compressor 106 providing a surface area to which various air compress...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com