Contouring toothbrush head

a technology of tooth brush and head, which is applied in the field of tooth brush, can solve the problems of premature splaying of the bristles, the inability to properly clean the tooth brush, etc., and achieves the effect of reducing manufacturing costs and inherent gentleness on the gums

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

second embodiment

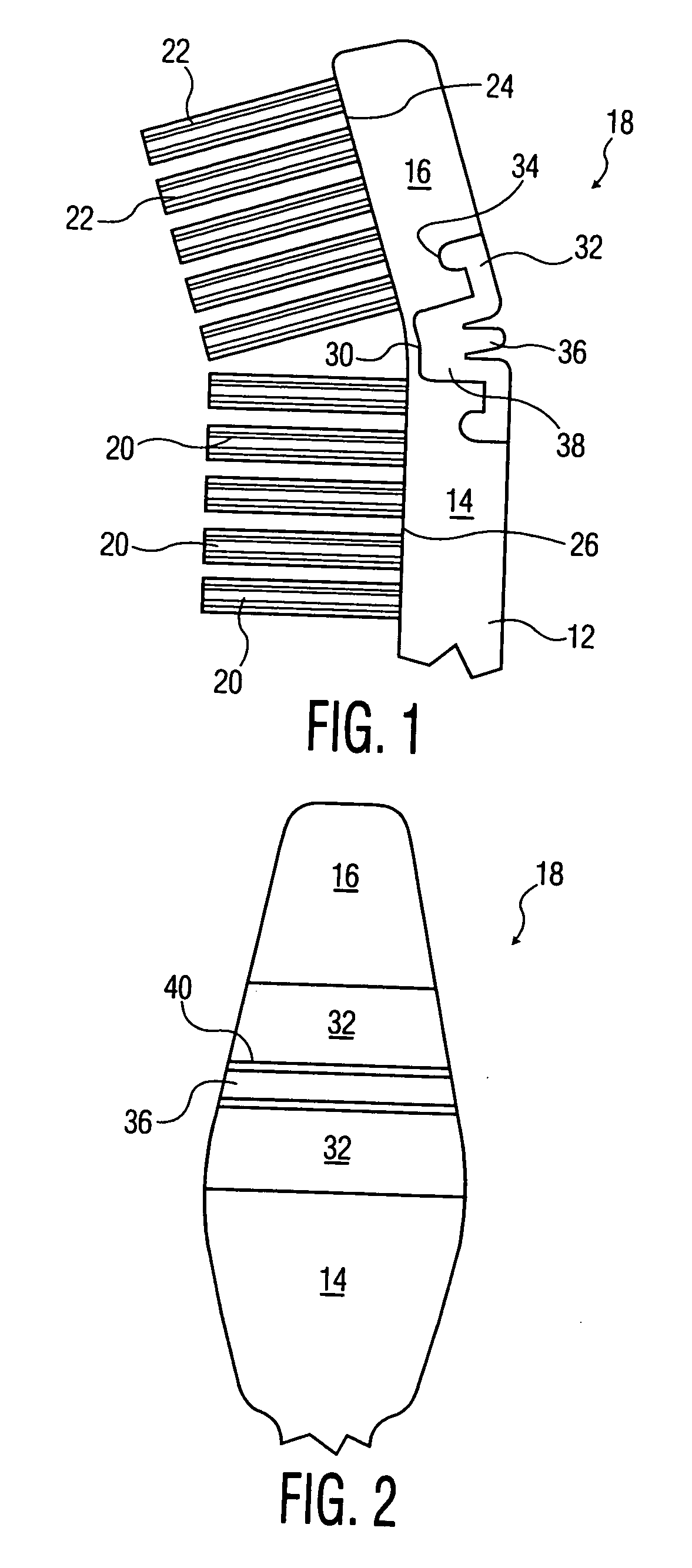

[0036]FIG. 4 illustrates the invention, there shown as horizontally disposed, and similar to that of FIGS. 1 and 2 except for a different construction for angularly joining the two head sections. The elastomer joint is again denoted as 18, with the elastomer itself denoted as 50 and being of the same composition as previously set out, and extends across the width of the head, and is located between the facing ends of sections 14 and 16. A thin integral bridge connection centrally between the two sections is designated as 52, typically being of cylindrical form in transverse cross section. Each end is integral with a respective head section. The elastomer is seen as completely surrounding bridge 52. This bridge connection may be, in transverse cross section, of any desired form. A top plan view of the head would be similar to FIG. 2, except for the absence of grooves 40 and rib 36. As seen at FIG. 4, the extent of the elastomer along the toothbrush longitudinal axis is shorter than t...

third embodiment

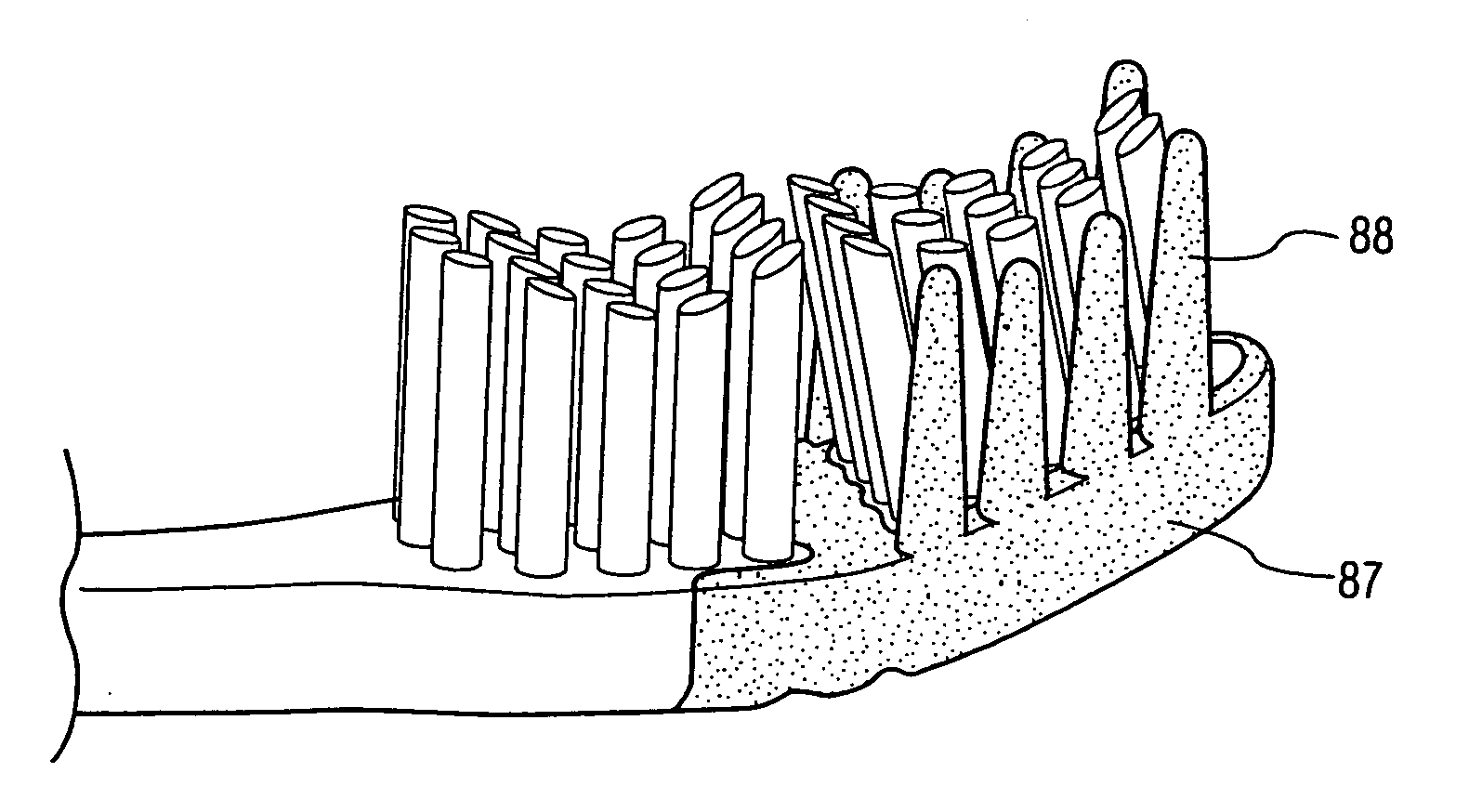

[0037]FIG. 5 shows a third embodiment, again shown as horizontal. There, the lower surfaces 24 and 26 of bristled head sections 14 and 16 are joined by an intermediate arcuate bottom surface 27 having tufts of bristles 23 extending orthogonally and downwardly therefrom. An elastomer section 18 is generally C shaped and has a bight part 60 and tips or ends 62, the latter located in respective complementary double troughs or double grooves which extend transversely across the head. The elastomer tips are separated by head portion 64, with thin bridges 66, again formed from the molded resin forming the toothbrush, joining the two head sections at the lower surface of the whole head. The C shaped elastomer thus surrounds portion 64 across the width of the head.

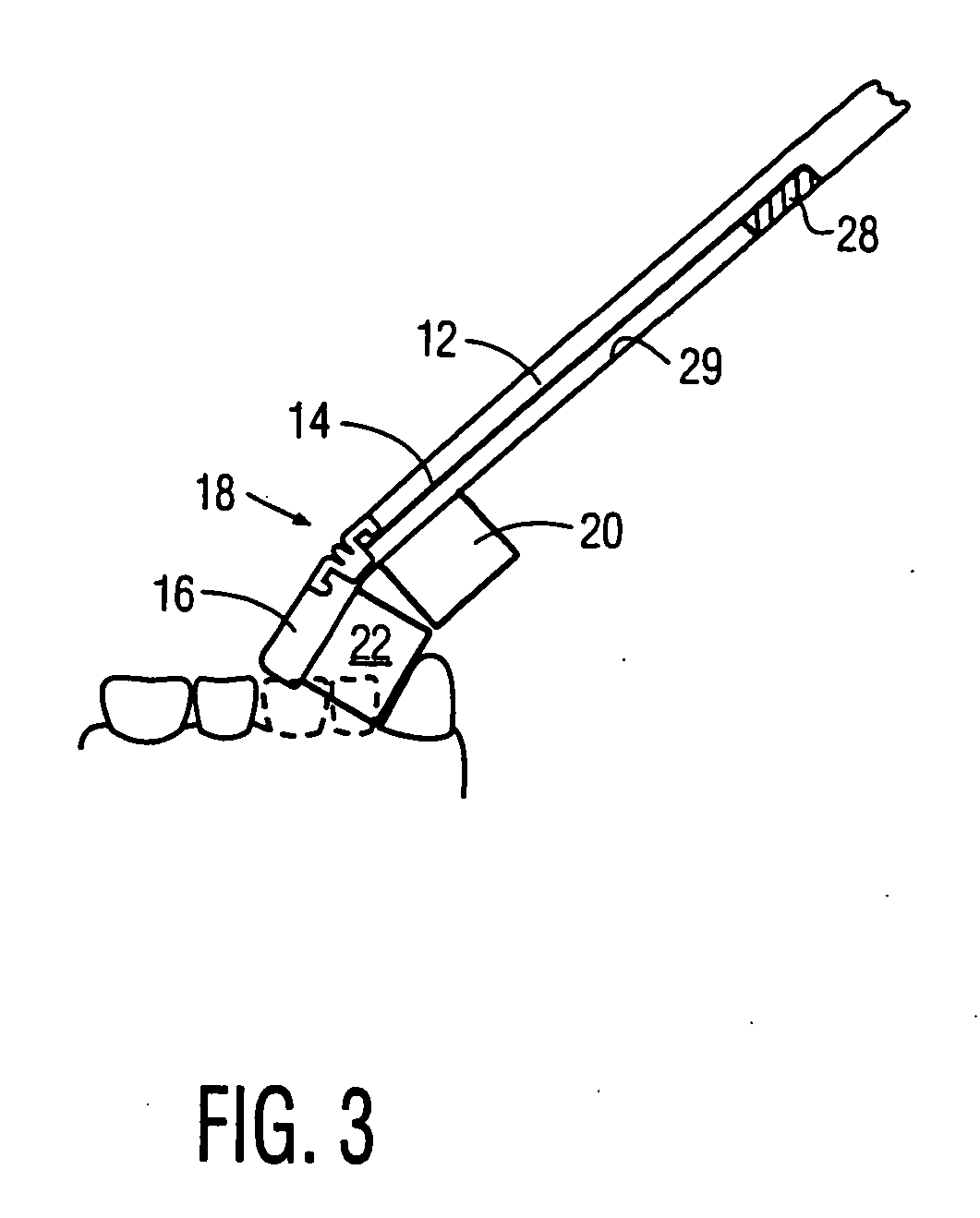

[0038] The second and third embodiments yield the same cleaning action as shown at FIG. 3. The thickness of bridges 52 and 66 is the same as that of bridge 30 of FIG. 1.

[0039] It is seen that the bridges 30, 52 and 66 of the resp...

fourth embodiment

[0040]FIG. 6 illustrates a fourth embodiment which differs from that shown in FIG. 1 only in the absence of bridge 30, of FIG. 1. Instead of bridge 30, the two head sections are coupled by T shaped elastomer section 39, the latter being of the same form as that of section 38 of FIG. 1, except that it extends all the way to the lower surface of the head.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com