Carton with dispenser

a dispenser and carton technology, applied in the field of cartons, can solve the problem that users can have difficulty in grasping the articles furthest from the dispenser

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

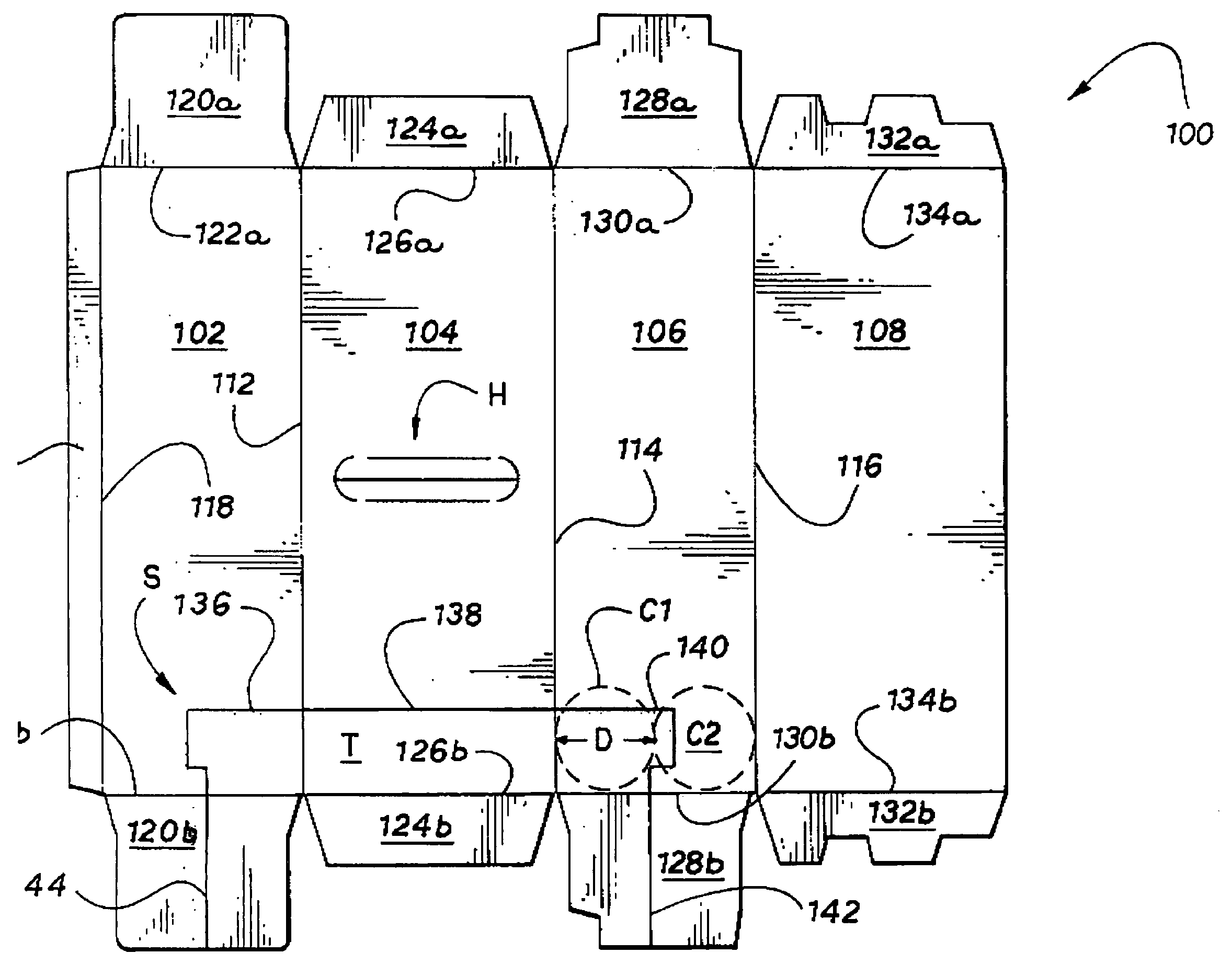

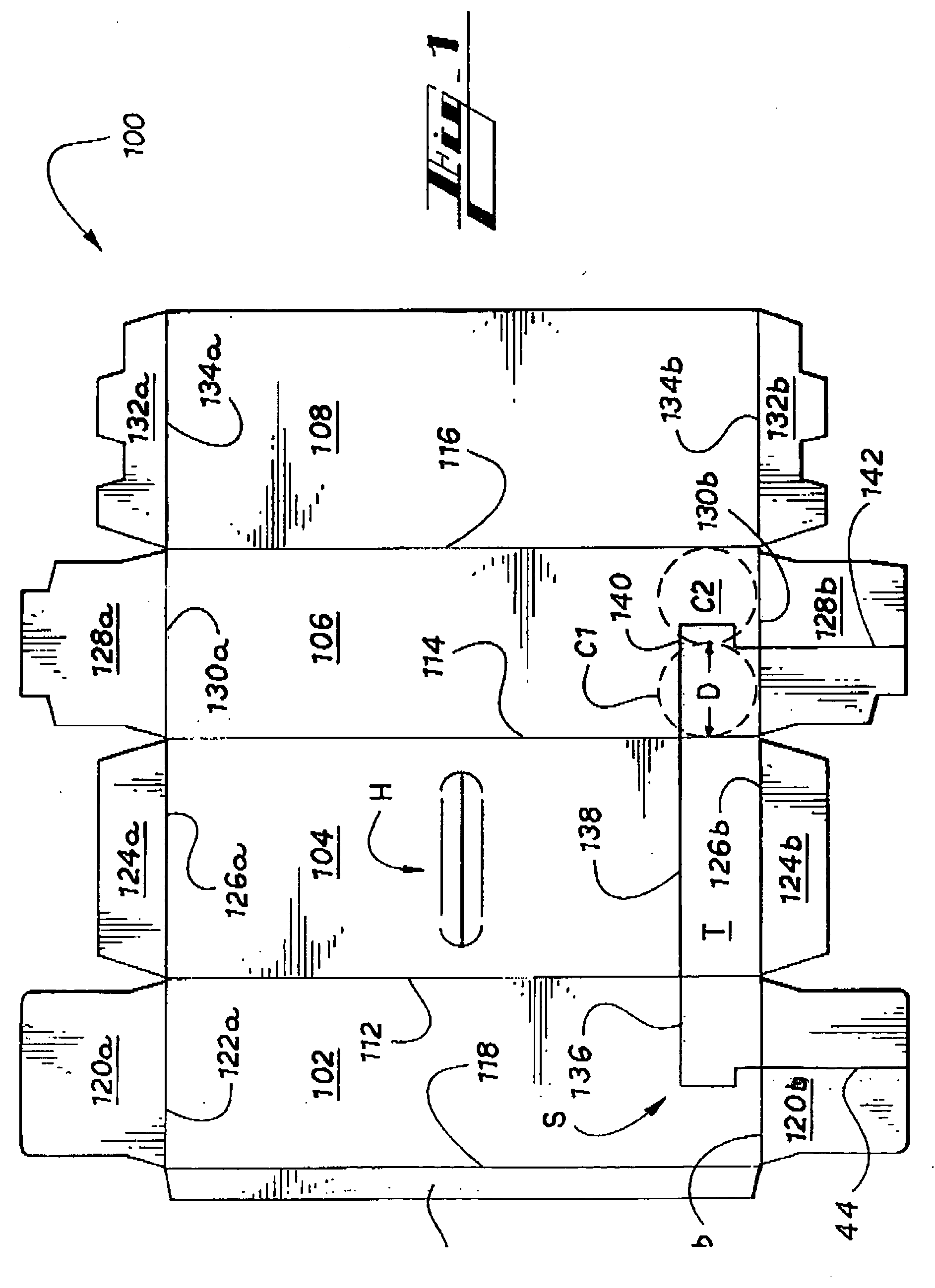

Method used

Image

Examples

second embodiment

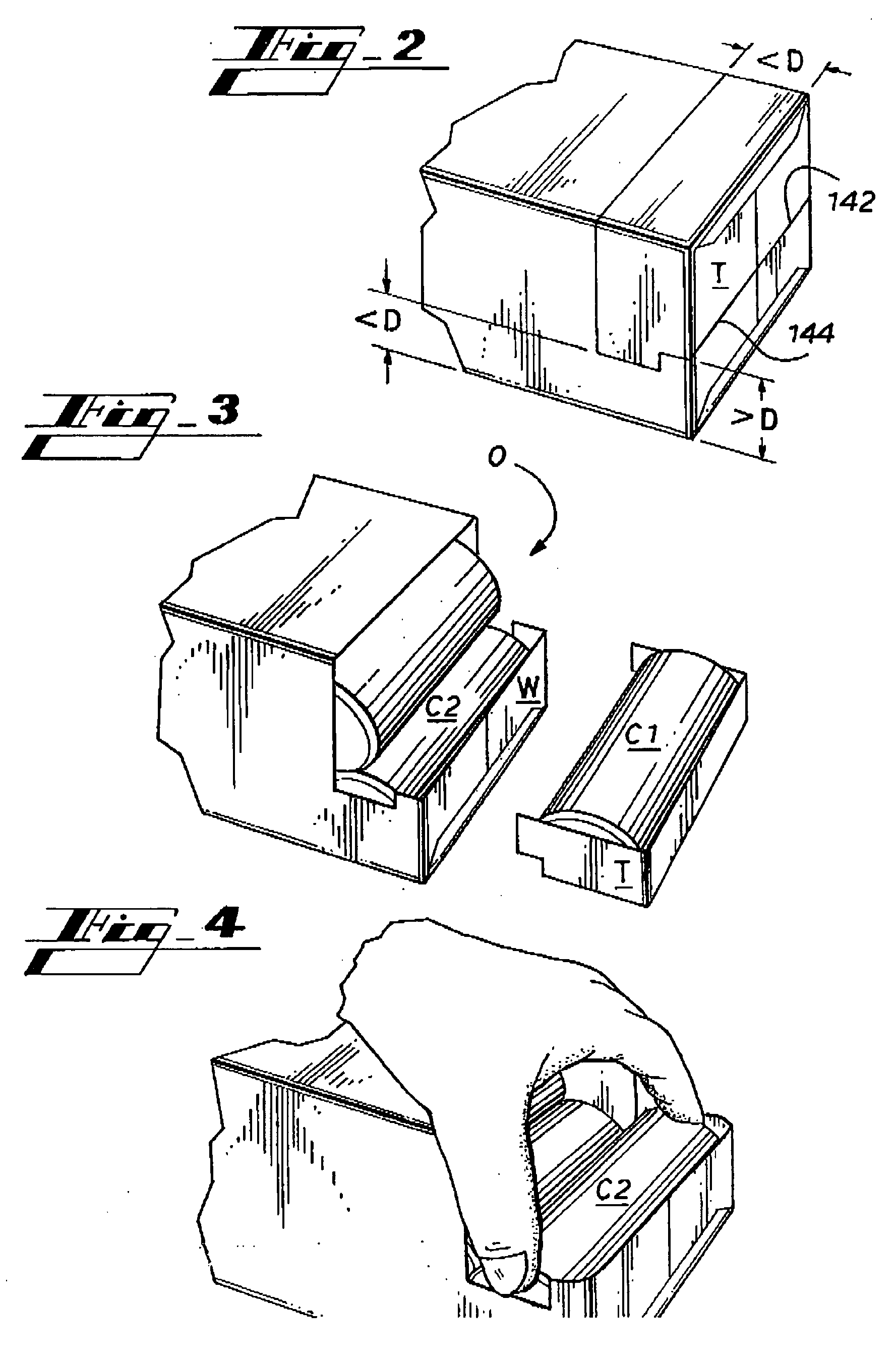

[0035]FIG. 5 is a plan view of a blank for forming a carton (shown in FIGS. 6 and 7) according to the invention, which further illustrates certain teachings thereof. This embodiment differs from the embodiment of FIGS. 1-4 in that the stopper wall W2 is vaulted at the center or otherwise convex with respect to the plane of the base wall to extend at least as far toward the top wall of the erected carton to provide retention for the articles remaining in the carton after the detachable portion T2 has been removed (FIG. 6), while providing at least as much visibility for the articles in the lower rows. The side wall severance lines 236, 240 are similarly disposed to provide access to the endmost article C2 in the lowermost row (FIG. 7).

[0036] The trough T is removed from the carton 100 by tearing severance line S. To ease detachment, there may further comprise tear-initiating means, as illustrated in FIGS. 8-11, and as will be described in greater detail below.

third embodiment

[0037]FIG. 8 is a plan view of a blank for forming a carton (shown in FIG. 9) according to the invention, which further illustrates certain teachings thereof. In addition to tear initiation means, this embodiment differs from the embodiment of FIGS. 5-7 in that the stopper wall W3 is concave with respect to the plane of the base wall. However, even the lowest point P, which may include an extended section, of the stopper wall W3 is disposed at a distance from the base wall that greater than the diameter D of the articles. Thus, the stopper wall W3 provides similar advantages as the previous embodiment, including retention and visibility for the articles remaining in the carton after the detachable portion T3 has been removed.

[0038]FIG. 10 is a plan view of a blank for forming a carton (shown in FIG. 11) according to a fourth embodiment of the invention, which further illustrates certain teachings thereof. In addition to tear initiation means, this embodiment differs from the embodim...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com