Tool cabinet

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] To make it easier for our examiner to understand the objects, features, and advantages of the present invention, the detailed description accompanied with drawings of a preferred embodiment are provided as follows.

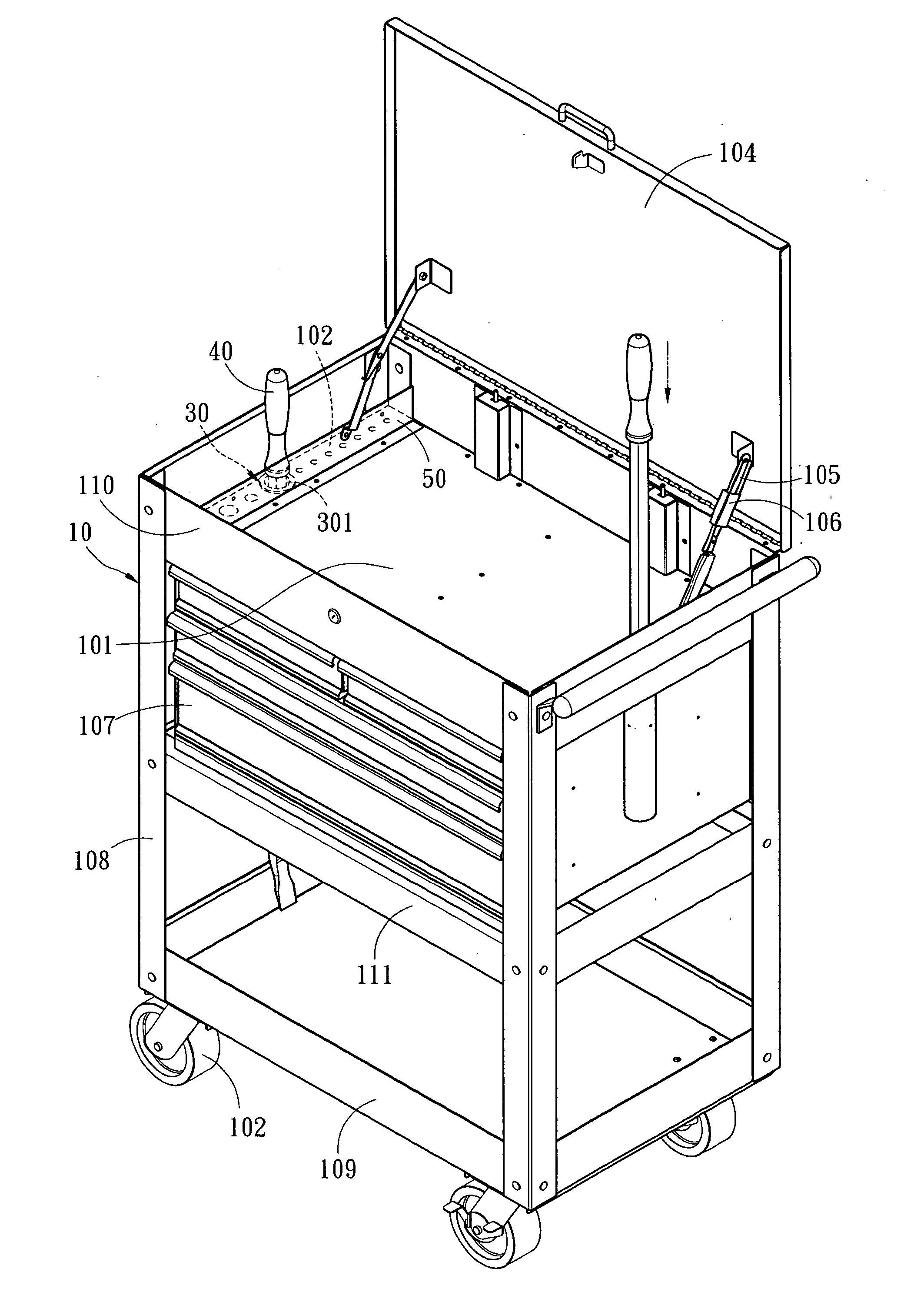

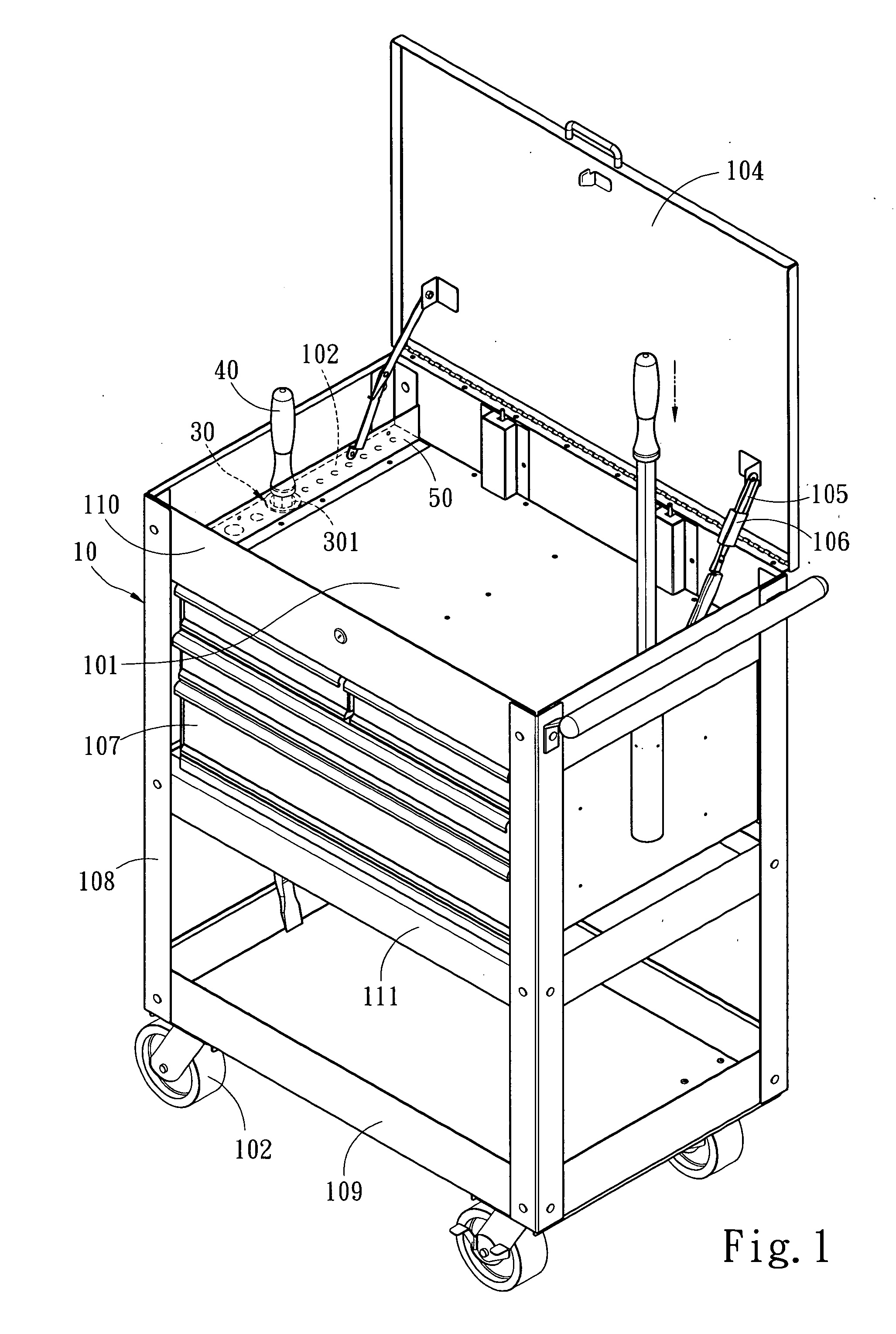

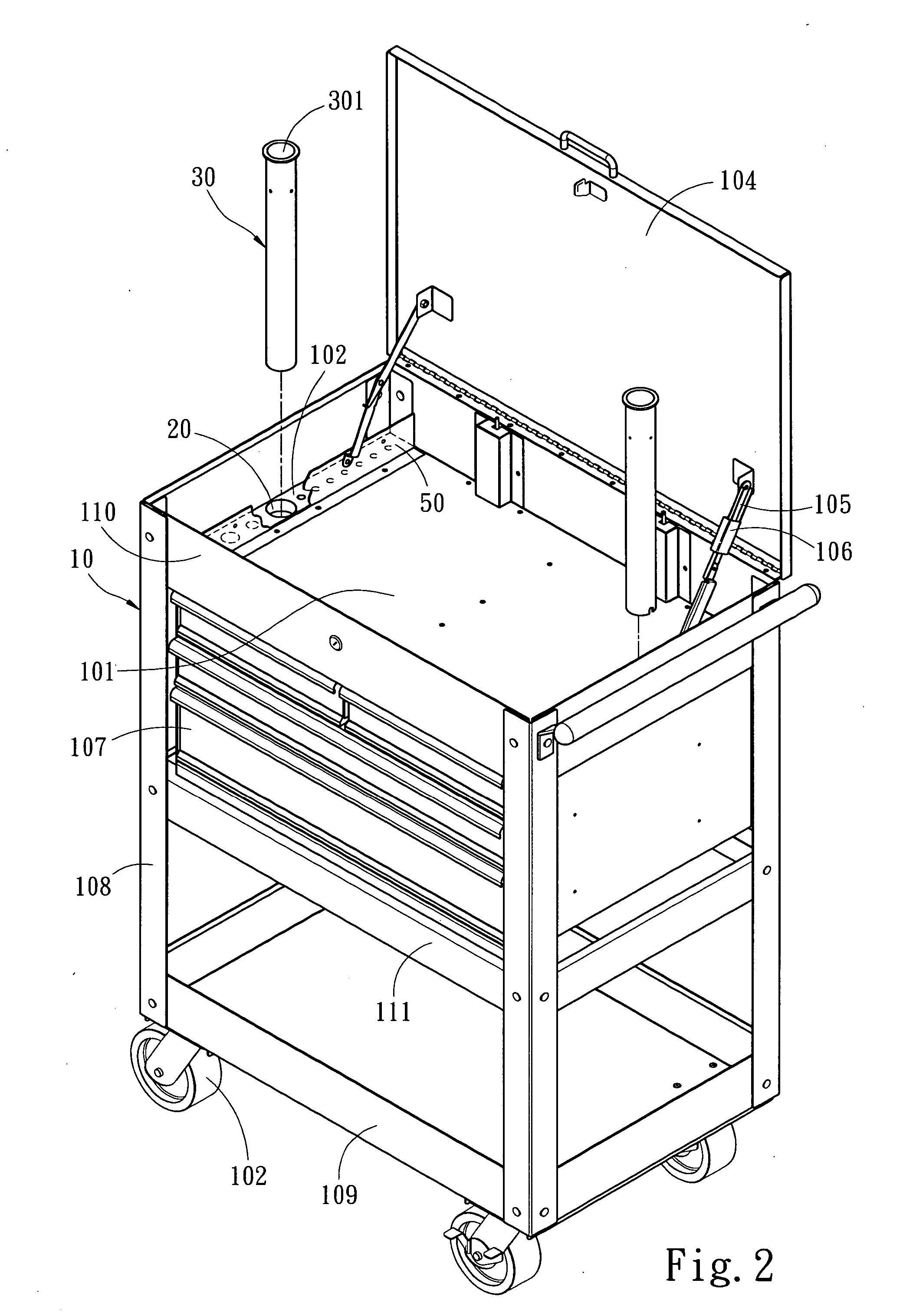

[0012] Please refer to FIGS. 1 and 2 for a tool cabinet in accordance with the present invention. The tool cabinet comprises a frame 10, and the frame 10 is made of four corner pillars 108 and at least one shelf 111 installed between the corner pillars 108. The shelf 111 includes an upper shelf 110 and a lower shelf 109, and the frame has at least one drawer 107 disposed therein for carrying objects, so that a user can store desired objects. The upper shelf 110 of the frame 10 has a carrying surface 101, and the lower shelf 109 has a movable wheel set 102. The carrying surface 101 has at least one installing hole 20 for accommodating a bar-shape hand tool 40. The installing hole 20 is usually built on both sides of the carrying surface 101, and a bar-shape protecti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com