Truck racing tire

a technology for trucks and tires, applied in the field of truck racing tires, can solve the problems of tire tread designs that are not optimal in temperature and weight characteristics, tire tread designs that are not optimal for truck racing applications, and tire tread designs that are not optimal in several key areas

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

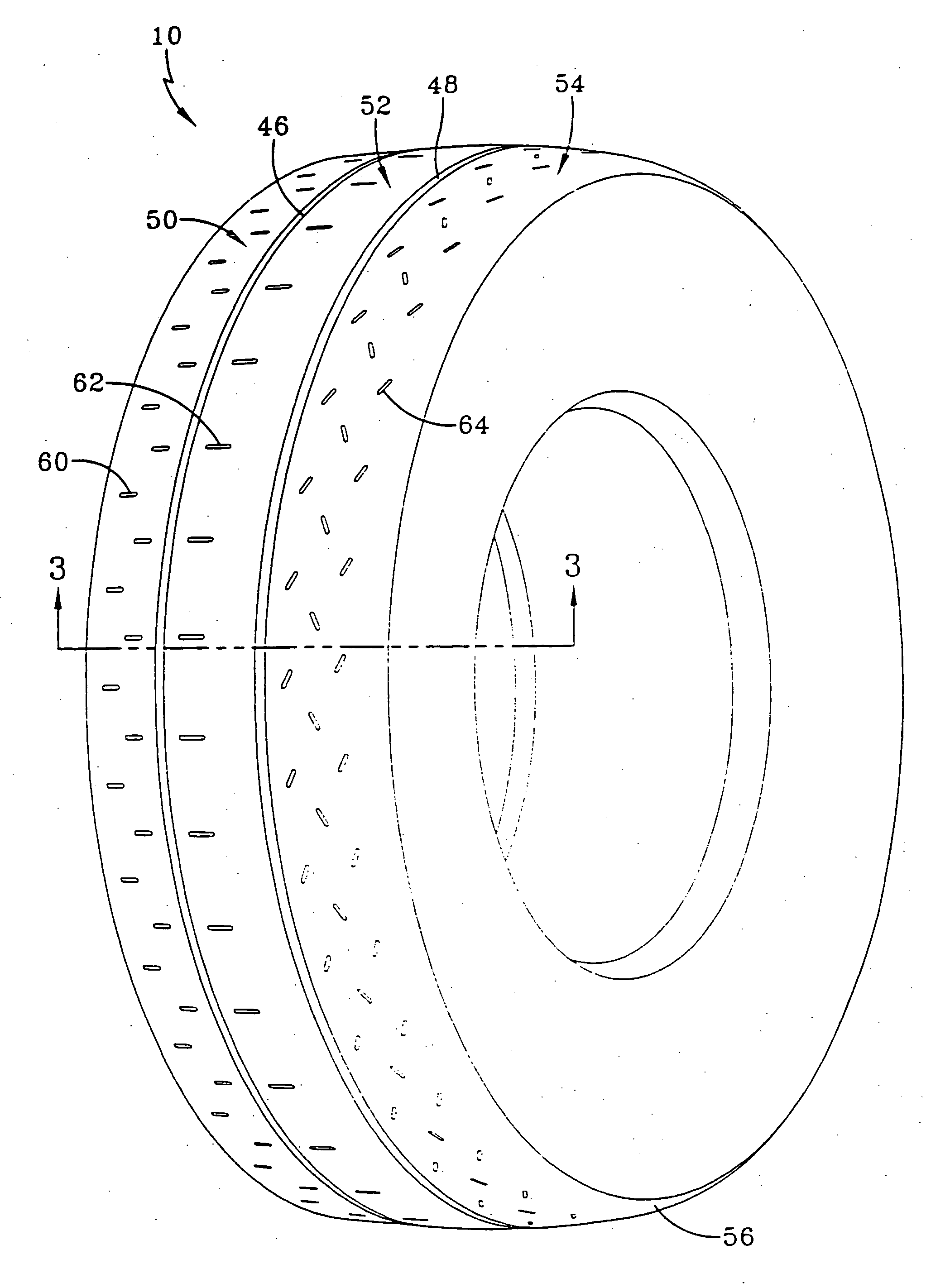

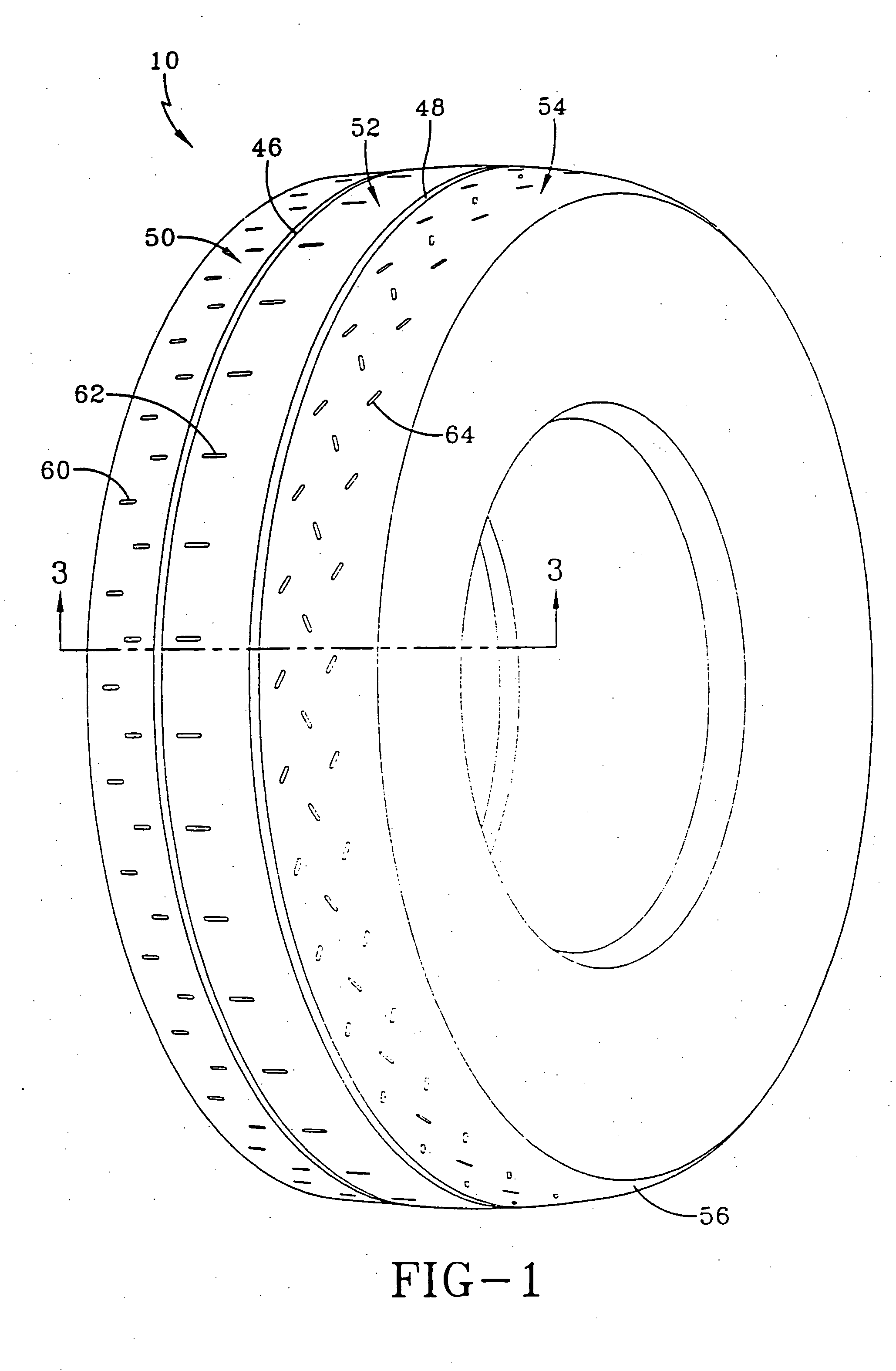

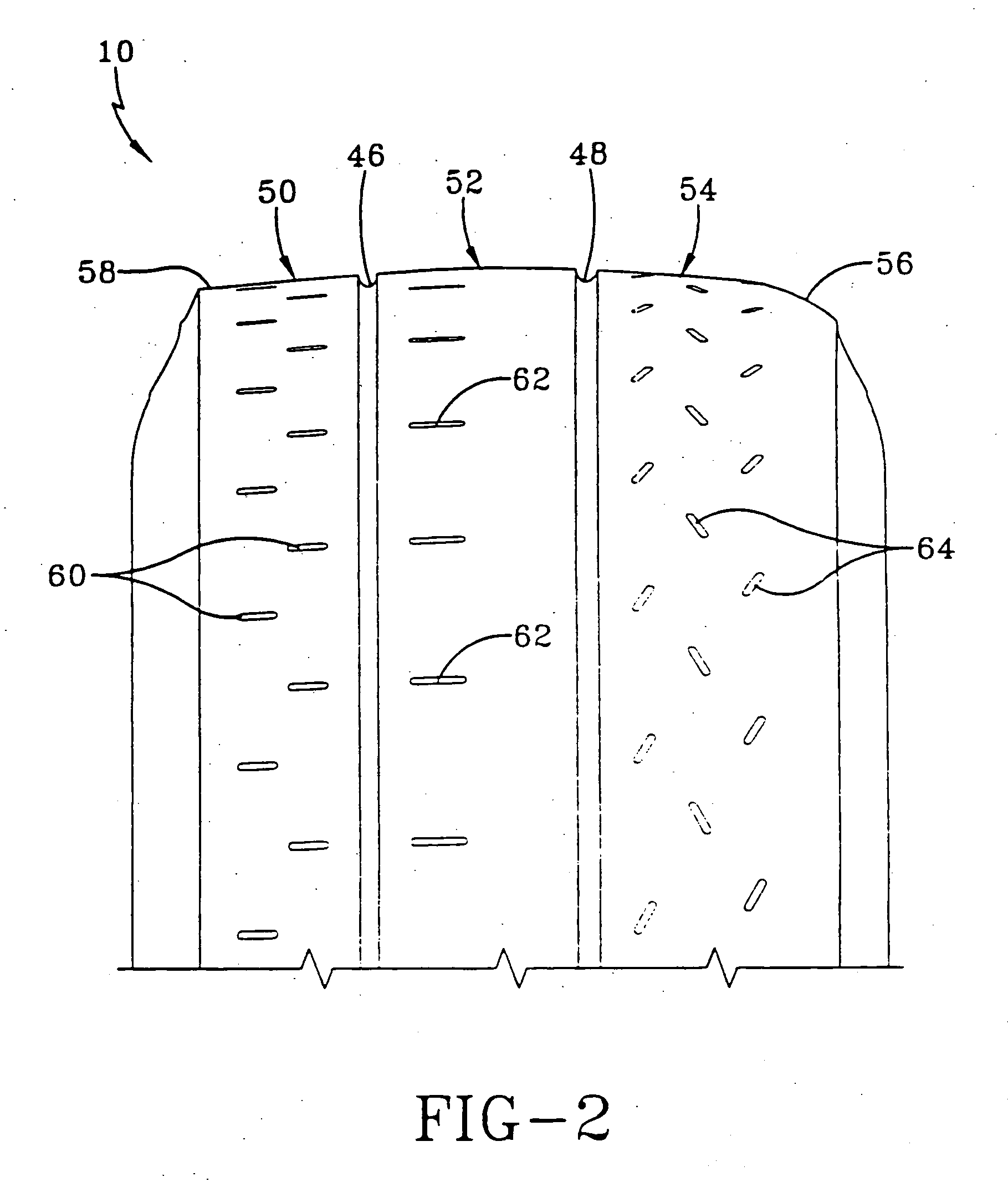

Image

Examples

example

[0090] Tread cap and base compounds are contemplated to be fabricated using the compound recipes as shown in Table 1. Cured compounds are contemplated to be tested and expected to have properties within the ranges shown in Table 2.

TABLE 1tread cap:tread base:S-SBR (15-25%70phrpolyisoprene100phrstyrene, 35-50%vinyl)polyisoprene30phrcarbon black (ASTM N100)42phrcarbon black77phrcure promoters10.7phr(ASTM N300)cure promoters10.7phrantidegradants6.5phrantidegradants4.5phrprocessing aids2phrprocessing aids37phrsilica15phrsulfur0.4phrsilane coupling agent2phrsilane coupling3phrsulfur0.9phragentsilica15phr

[0091]

TABLE 2tread cap:tread base:@ 23° C.:@ 23° C.elongation400-500%elongation470-520%true tensile77-83 MPatrue tensile135-150 MPamodulus 300%9-11 MPamodulus 300%13-15.5 MPatensile strength14-15 MPatensile strength22-25 MPashore A63-68shore A63-67hardnessrebound20-25%rebound50-55%@ 100° C.:@ 100° C.:elongation300-350%tan delta 10% @ 100° C.0.115-1.145true tensile27-32 MPaG* 10% @ 100° ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com