Modular Snowmobile Platform

a technology of snowmobile platform and module, which is applied in the direction of vehicle components, rider propulsion, transportation and packaging, etc., can solve the problems of critical weight of racing snowmobile, consuming a significant number of engineering hours, and each new vehicle consuming a significant number of training hours

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041]FIG. 3 illustrates one possible embodiment of a snowmobile 100 designed and constructed in accordance with the teachings of the present invention. The snowmobile 100 has a front end 102 and a rear end 104. The front end 102 is provided with one or more fairing elements 106, including a bottom pan 108, a side panel 110, and a motor cover 112 As would be understood by those skilled in the art, the front end 102 of the snowmobile 100 houses the engine (not shown) beneath the fairing elements 106. A front suspension 114 is connected at the front end 102 of the snowmobile 100. As with the prior art snowmobile, two skis 116 are suspended from the front suspension 114.

[0042] The endless track 118 that is operatively connected to the engine is disposed beneath the rear end 104 of the snowmobile 100. A seat 120 is positioned generally above the endless track 118. A windshield 122 is disposed atop the fairing elements 106 at the front end 102 of the snowmobile 100. A handlebar (not sho...

PUM

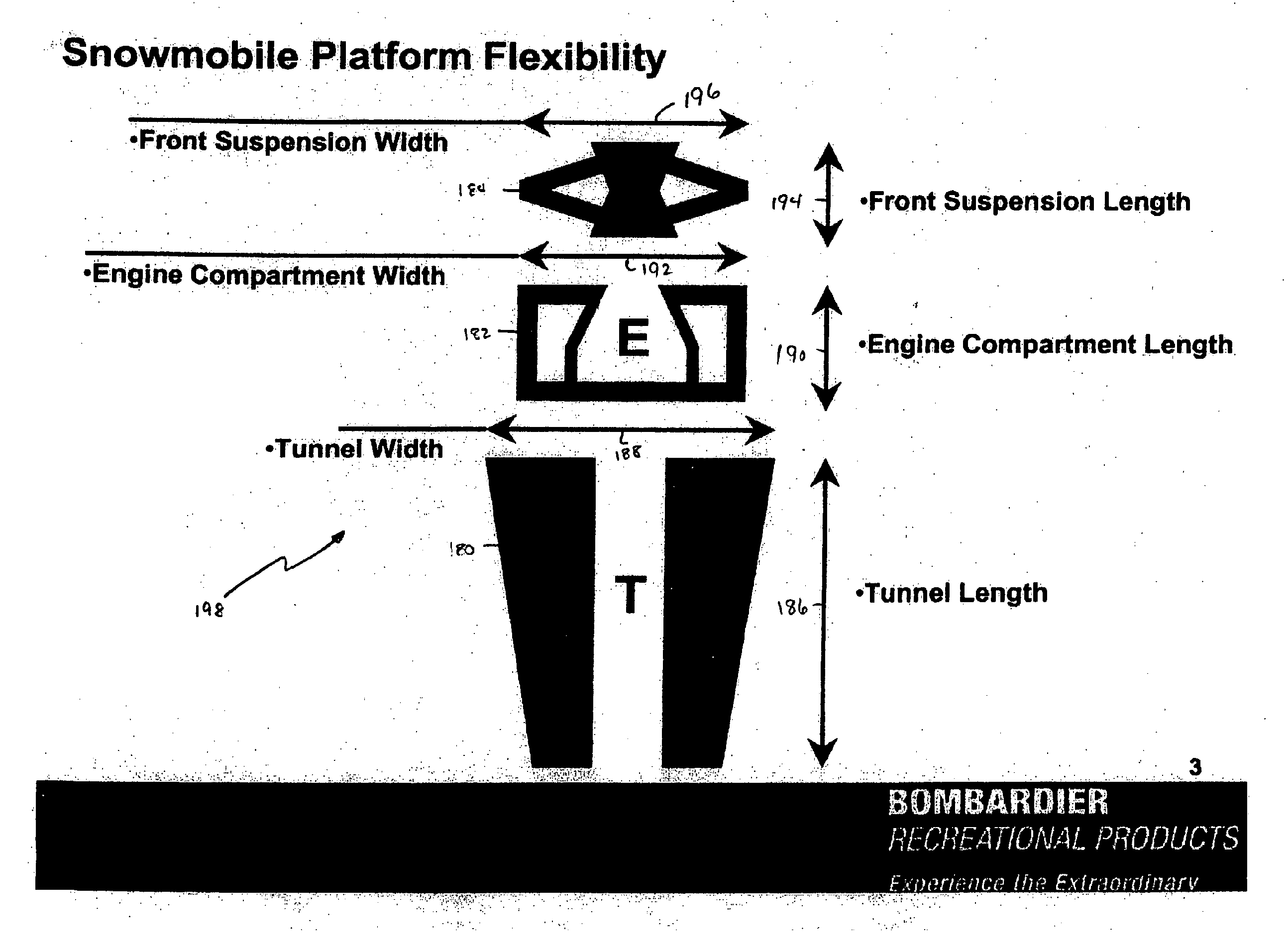

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com