Stuffing box assembly and sealing assembly for use therein

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

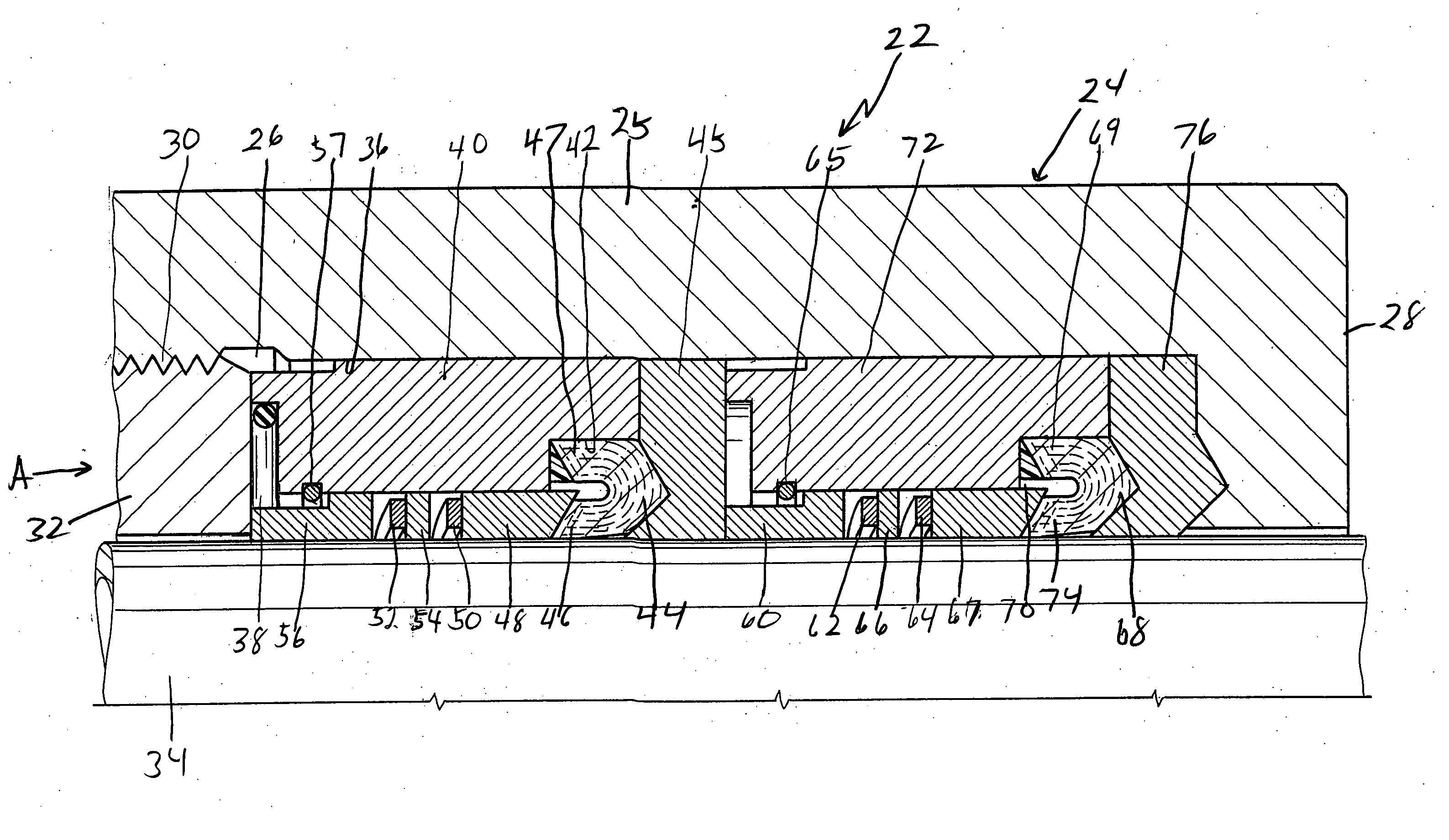

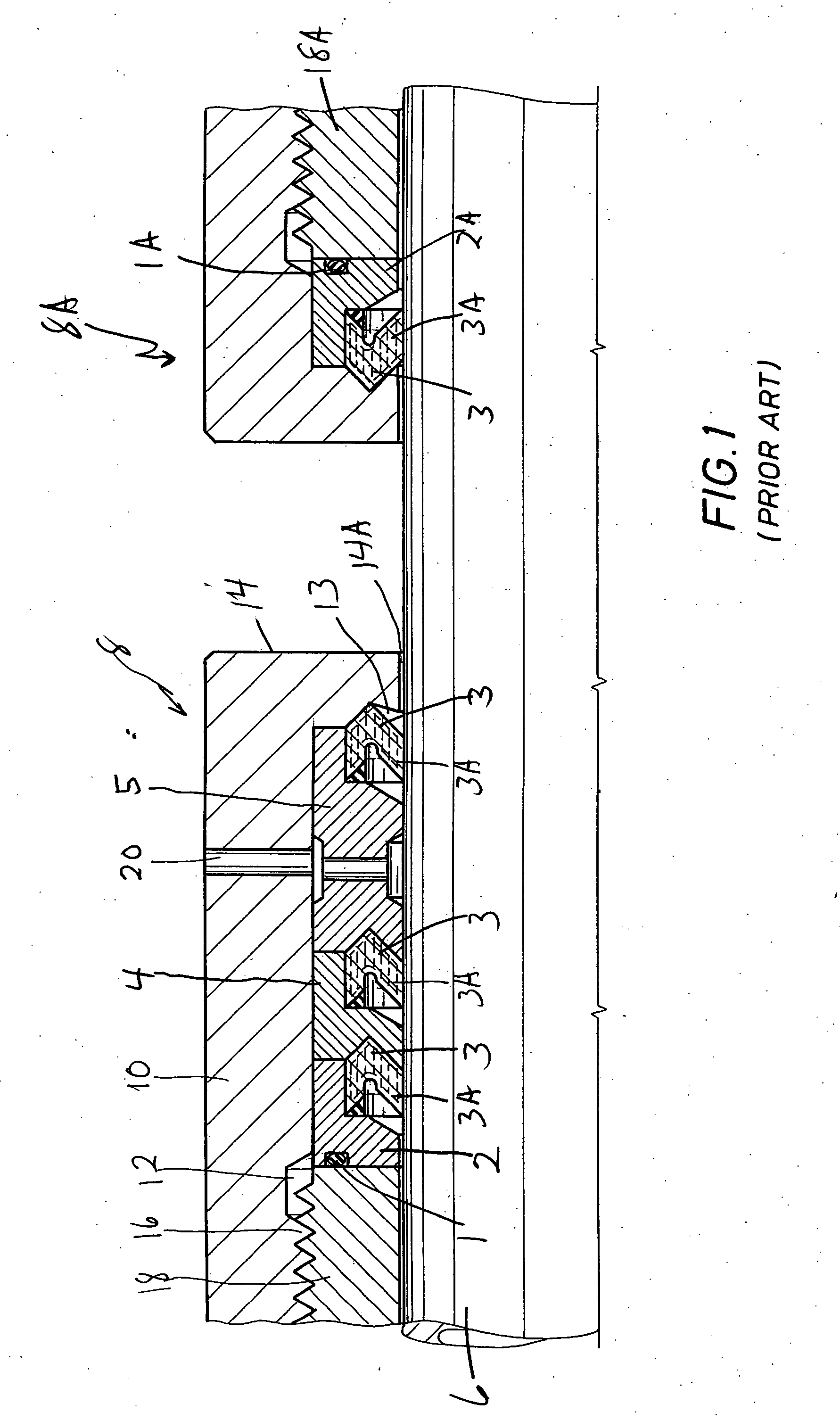

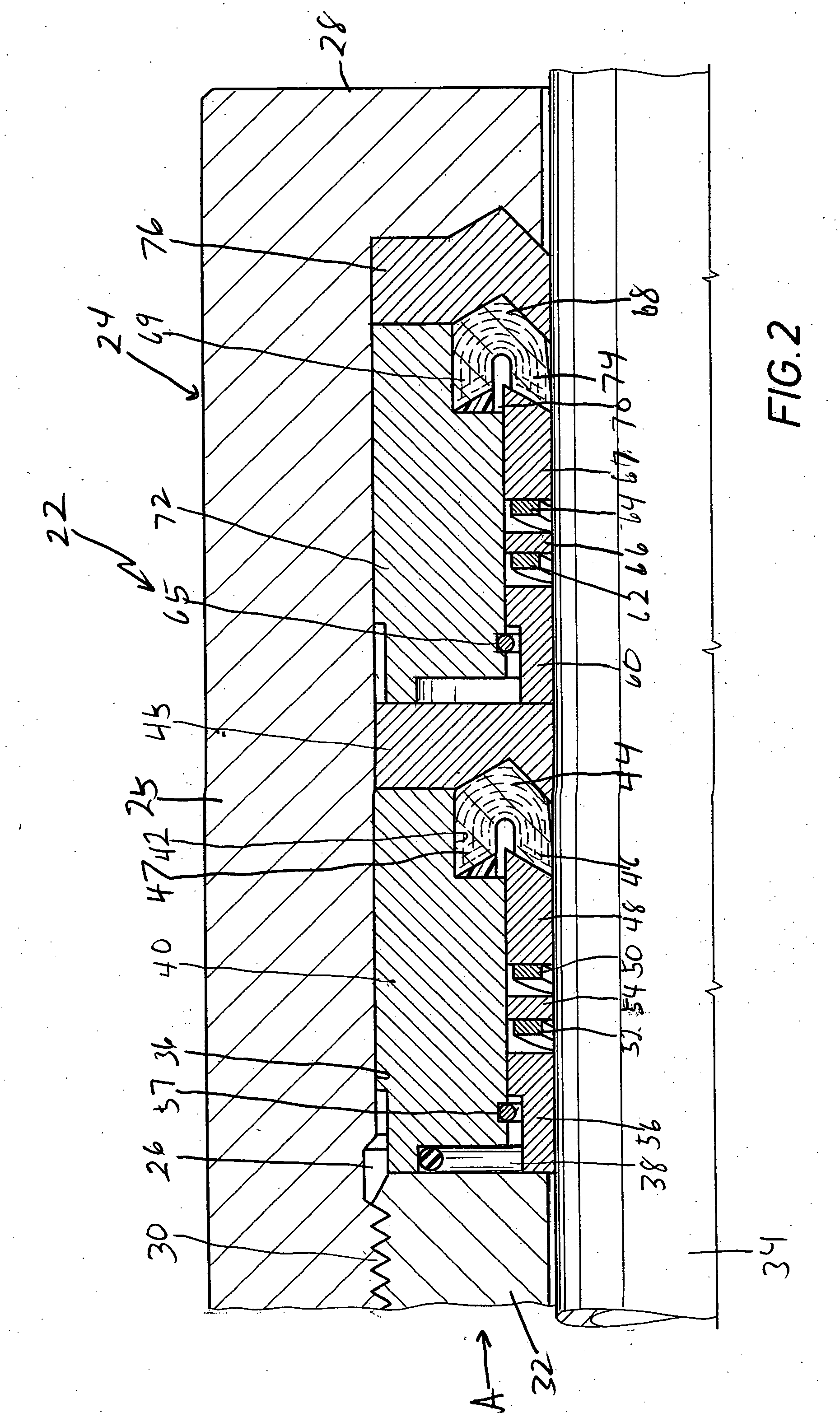

[0017] Referring first to FIG. 1, there is shown a wash pipe / stuffing box or packing gland assembly used in a conventional rotary drilling swivel, the stuffing box assembly including a conventional prior art sealing or packing assembly, all of which are well known to those skilled in the art. Referring then to FIG. 1, a wash pipe 6 extends through a stuffing box assembly shown generally as 8 comprising a packing gland or stuffing box housing 10 forming an annular chamber 12 in surrounding relationship to wash pipe 6. Housing 10 has a first end wall 14 having a bore 14A therethrough and a second end (partially shown) which is threaded as at 16 to receive a threaded follower 18. As seen, there is a second stuffing box assembly 8A which is substantially a mirror image of assembly 8. Positioned in the annulus in chamber 12 surrounding wash pipe 6 is an annular seal ring carrier 2 which is sealed against follower 18 by means of an O-ring 1. An annular lip type seal ring 3 carried by carr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com