Digital transfer method for printing on a target surface

a transfer method and target surface technology, applied in biochemistry equipment, biochemical equipment and processes, recording equipment, etc., can solve the problems of less complicated procedures, less expensive and time-consuming offset printing processes, and limited use of particular materials, so as to achieve clearer, eye-catching

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

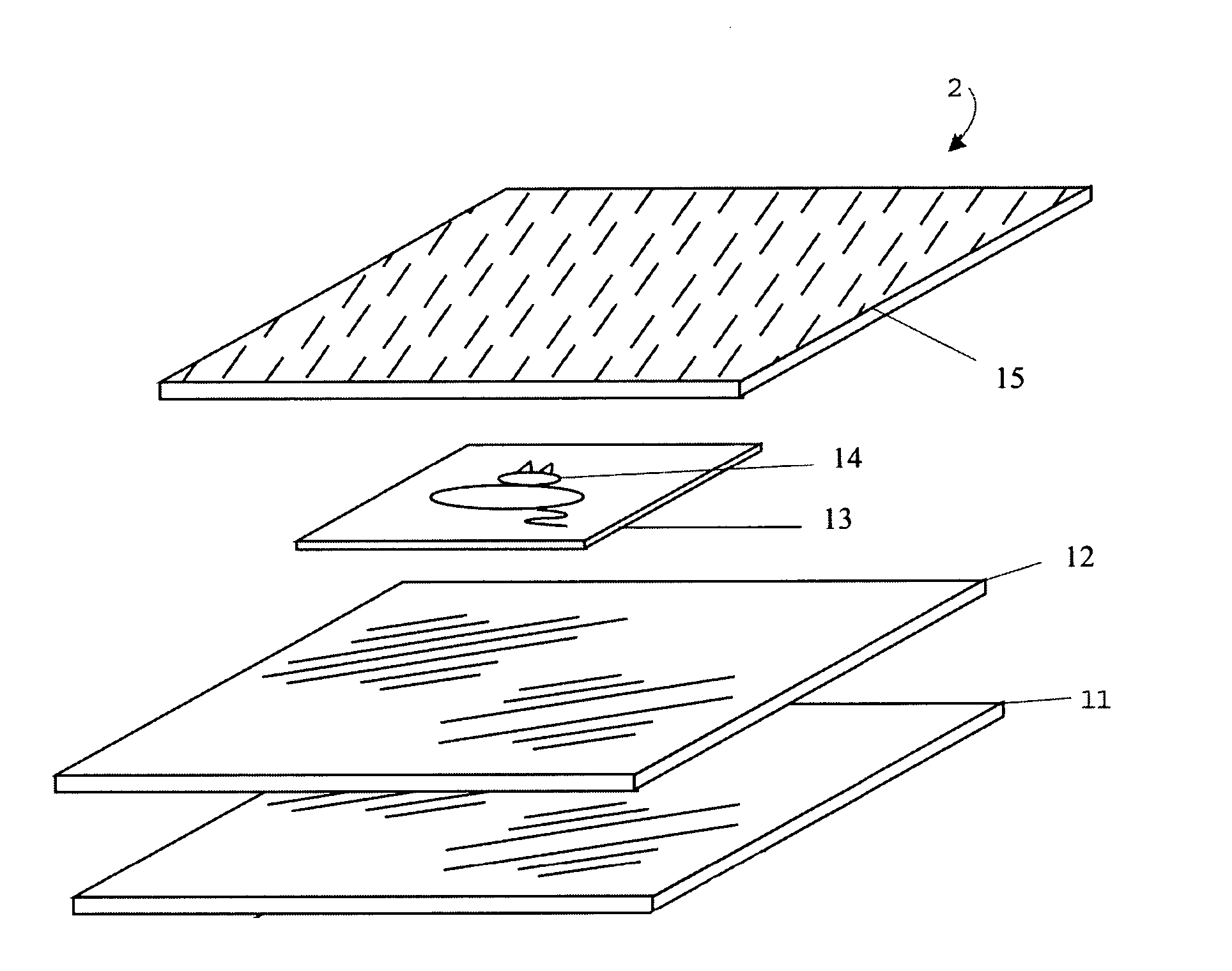

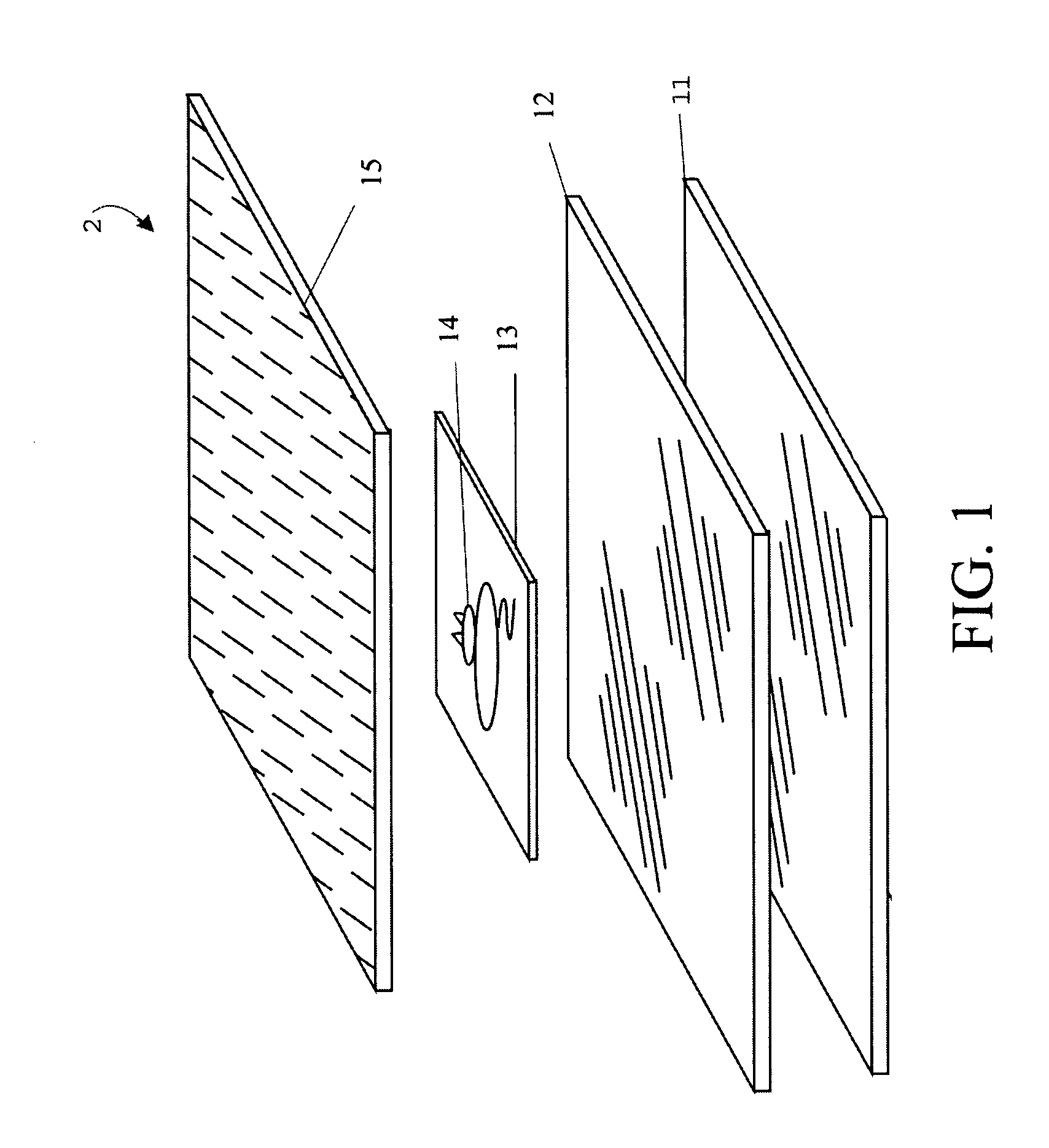

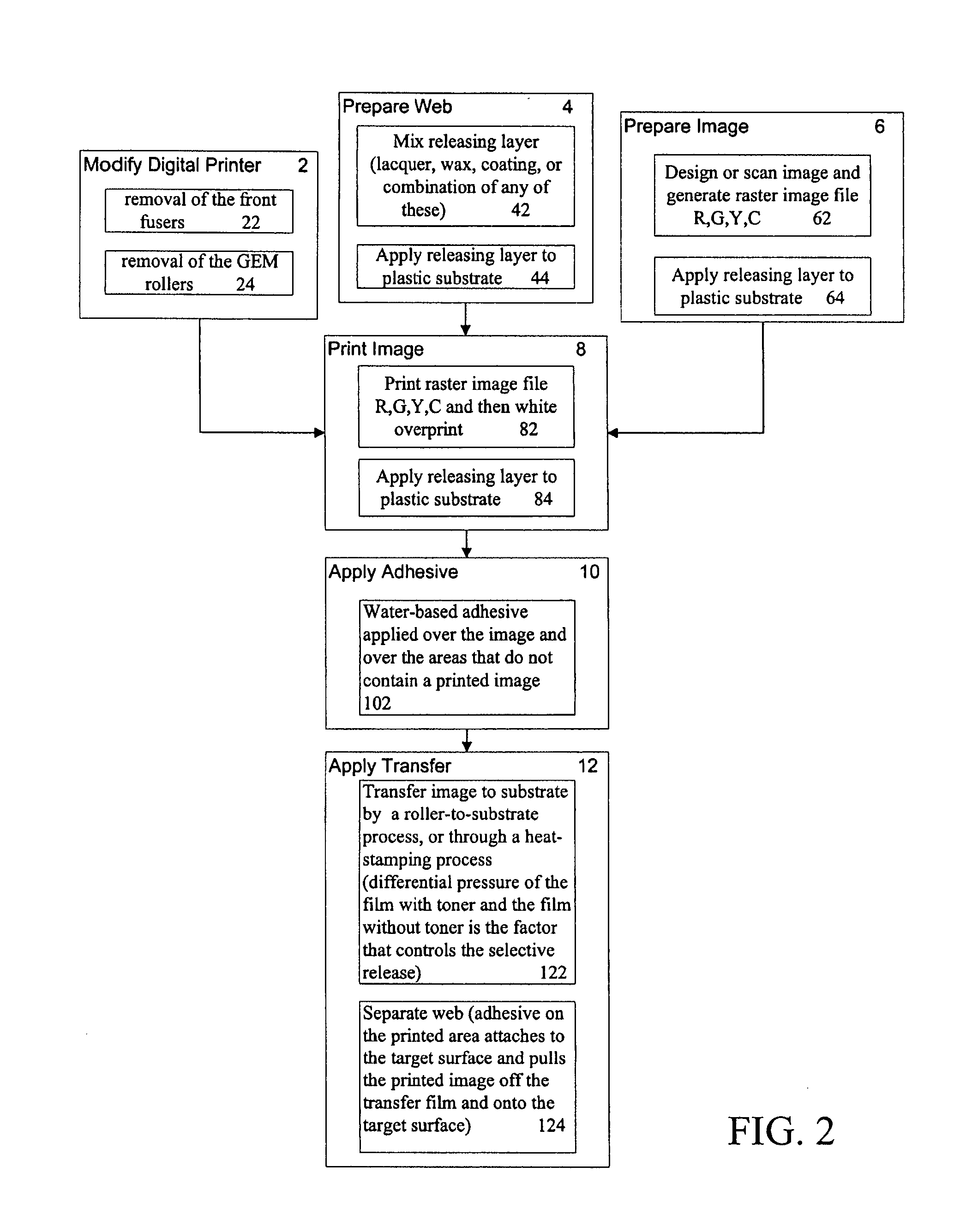

[0019] The present invention is a digitally-printed transfer bearing a digitally created image that can be heat and / or pressure-applied to a target surface, and a method for transferring the digitally created images from film to a target surface via digital printing and heat and / or pressure transfer.

[0020] The process employs a modified digital printer (converted from a double sided fusing printing process to a back fusing web printing process) to create an image on transfer film subsequently coated with adhesive that is then heat and / or pressure-applied to a substrate to yield a high-resolution four color graphic with white.

[0021] The basic fabrication steps comprise 1) coating one side of a disposable base transfer film (or carrier) with a releasable coating; 2) digitally printing one or more images overtop the base transfer film in reverse-image format; and 3) applying an adhesive coating over the image.

[0022] The result is a roll of pre-printed transfers. In accordance with t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pressure | aaaaa | aaaaa |

| fluorescent | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com