Camera integrated firearm system and method

a firearm system and integrated technology, applied in the field of integrated firearm systems and methods, can solve the problems of unreliable, conflicting witnesses, and often unreliable, and achieve the effect of maintaining weapon accuracy, reliability, and safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

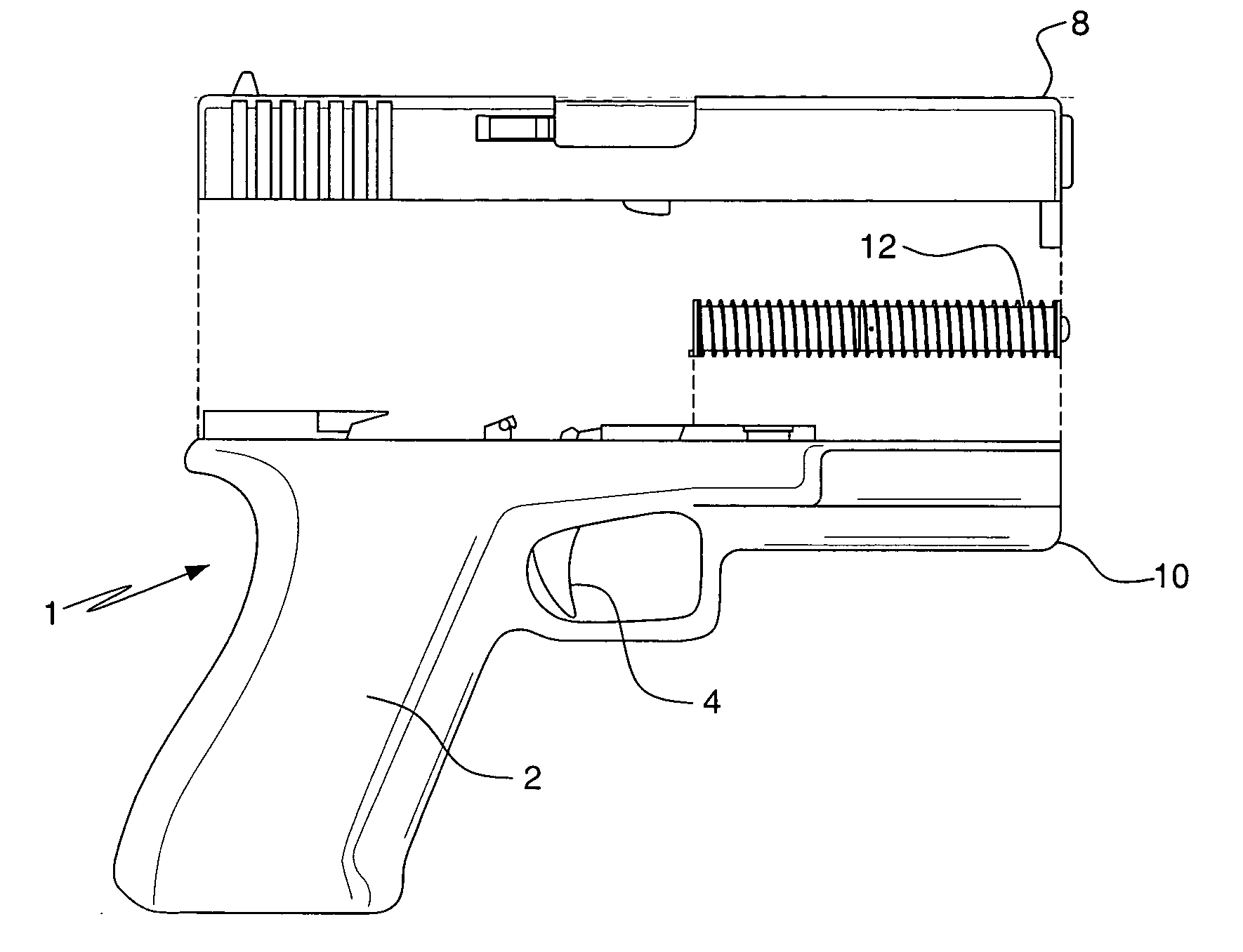

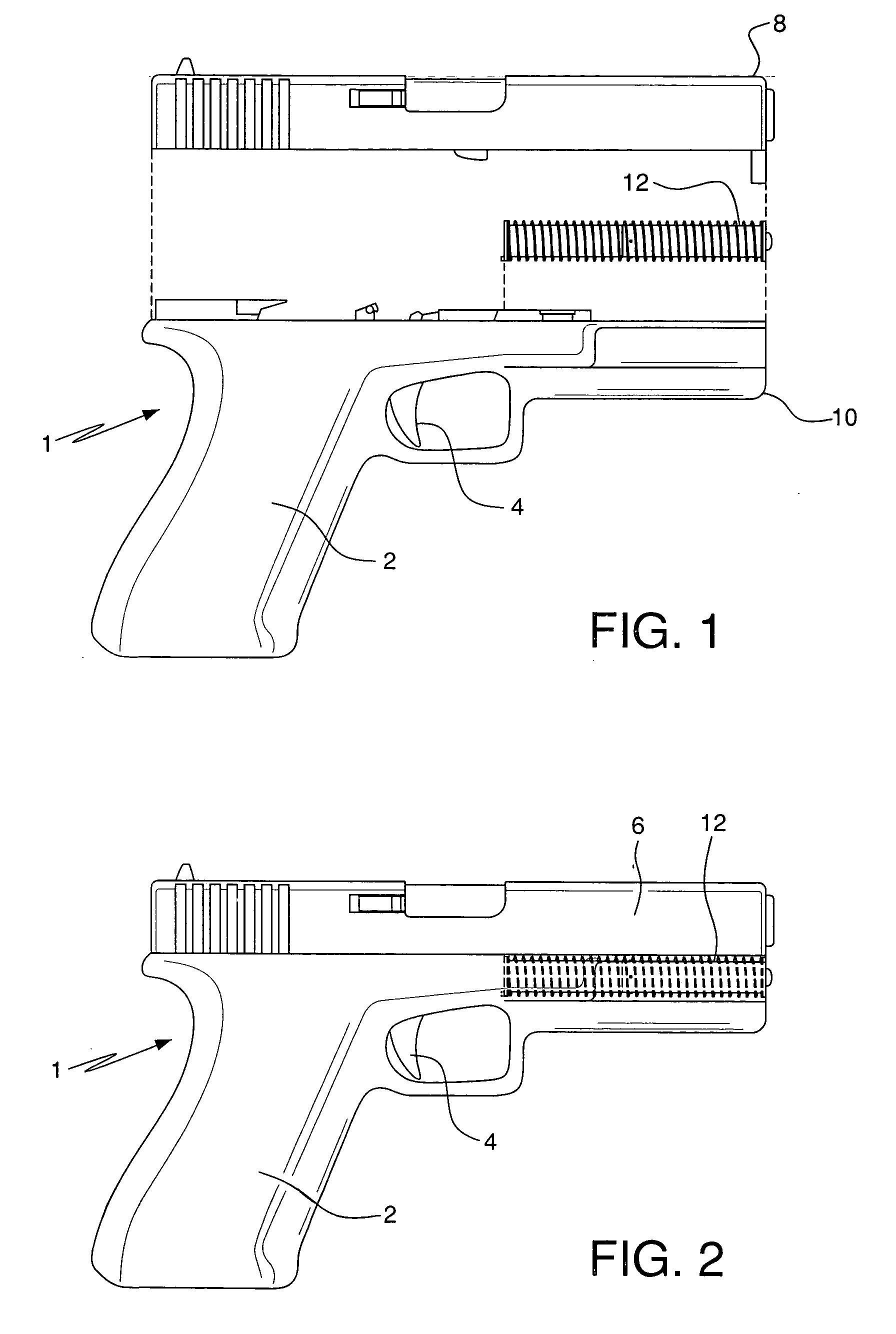

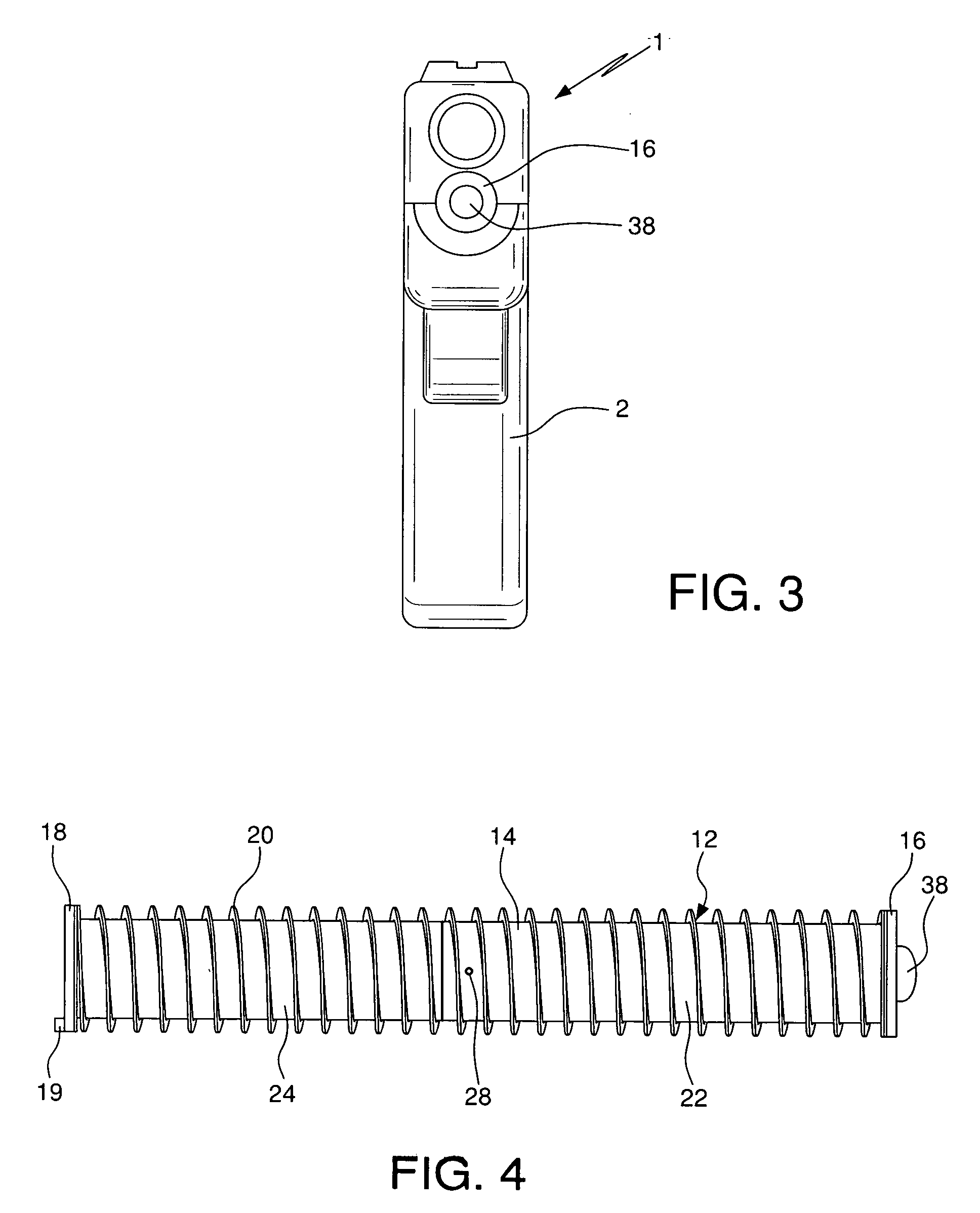

[0021]Handgun 1 comprises gun body 2 having trigger 4 and gun barrel or muzzle 6, with upper half 8 and lower half 10. Recoil spring guide camera assembly 12 is configured to replace the standard recoil spring guide in lower half 10 of muzzle 6 of the gun. Assembly 12 comprises outer casing or housing 14. Casing 14 is optimally made of corrosion resistant steel or similar metal. Recoil spring 20 circumscribes housing 14. Recoil spring retention walls 16 and 18 of assembly 12 are located at the ends of casing 14. Raised notch 19 is provided on the back of rear wall 18. The notch indexes the slot in the receiver (not shown) in lower portion 10 of gun 1, in order to maintain orientation of assembly 12.

[0022]Casing 14 is comprised of front section 22 and rear section 24. Sections 22 and 24 are threadably connected at 26 and secured with barrel locking screws 28. An O-ring spacer 29, provides a secure seal between sections 22 and 24.

[0023]Rear section 24 comprises open space 30 in which ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com