Golf club head structure

a golf club and head technology, applied in the field of golf club head, can solve the problems of golf ball flying non-smoothly and in the wrong direction, golf ball is relatively difficult to make an accurate golf shot with the golf club, and the golfer's hands are injured, so as to increase the ability of the club head to bear force and reduce the reaction of the golf ball.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

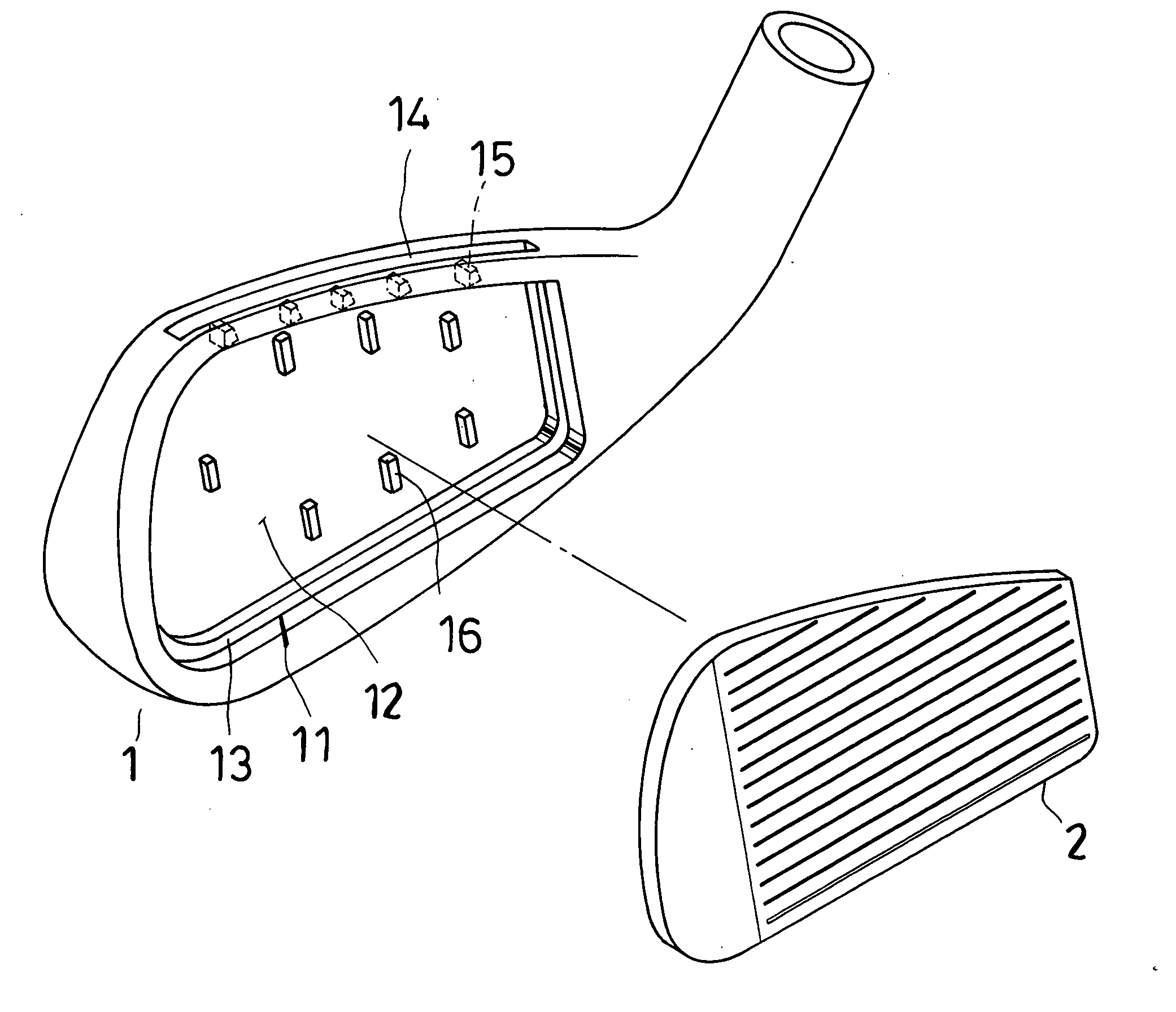

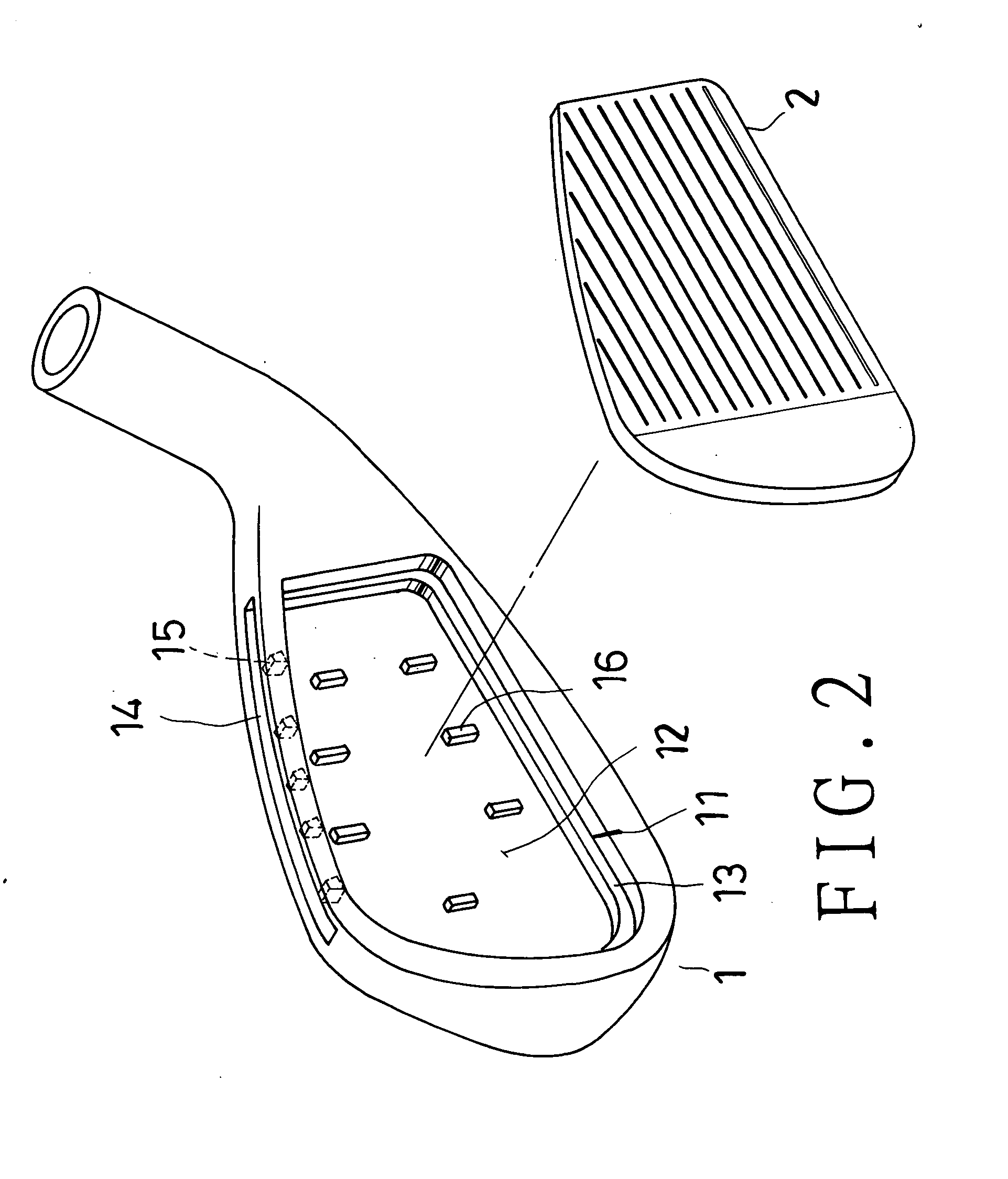

[0015]Referring to FIGS. 2 to 4, a preferred embodiment of a head of a golf club consists of a shell part 1, and a face part 2. The shell part 1 is made of metallic materials, e.g. stainless steel, by means of casting. The shell part 1 has a front opening 11, a truncated cone shaped inner circumferential side around the front opening 11, a holding hollowness 12 behind the front opening 11, and a protruding portion 13 on an inward end of the truncated cone shaped inner circumferential side. Furthermore, the shell part 1 has a slot 14 on an upper side thereof, which communicates with the holding hollowness 12. The slot 14 has several connecting blocks 15 therein, which are each connected to two lateral sides of the slot 14. A few strengthening pieces 16 are held in the holding hollowness 12. Therefore, the upper portion of the club head, on which the slot 14 and the connecting blocks 15 are provided, can bear more force, preventing damage and deformation to the club head if the golf c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com