Sofa-Bed with Innovative Elements for Assembly and Position Adjustment

a technology of positioning adjustment and assembly, which is applied in the direction of sofas, beds, couches, etc., can solve the problems of long assembly time, inability to ensure a good coupling between the base structure and the frame, and inability to ensure the tolerance of machining

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0008]With reference to the above mentioned tables:

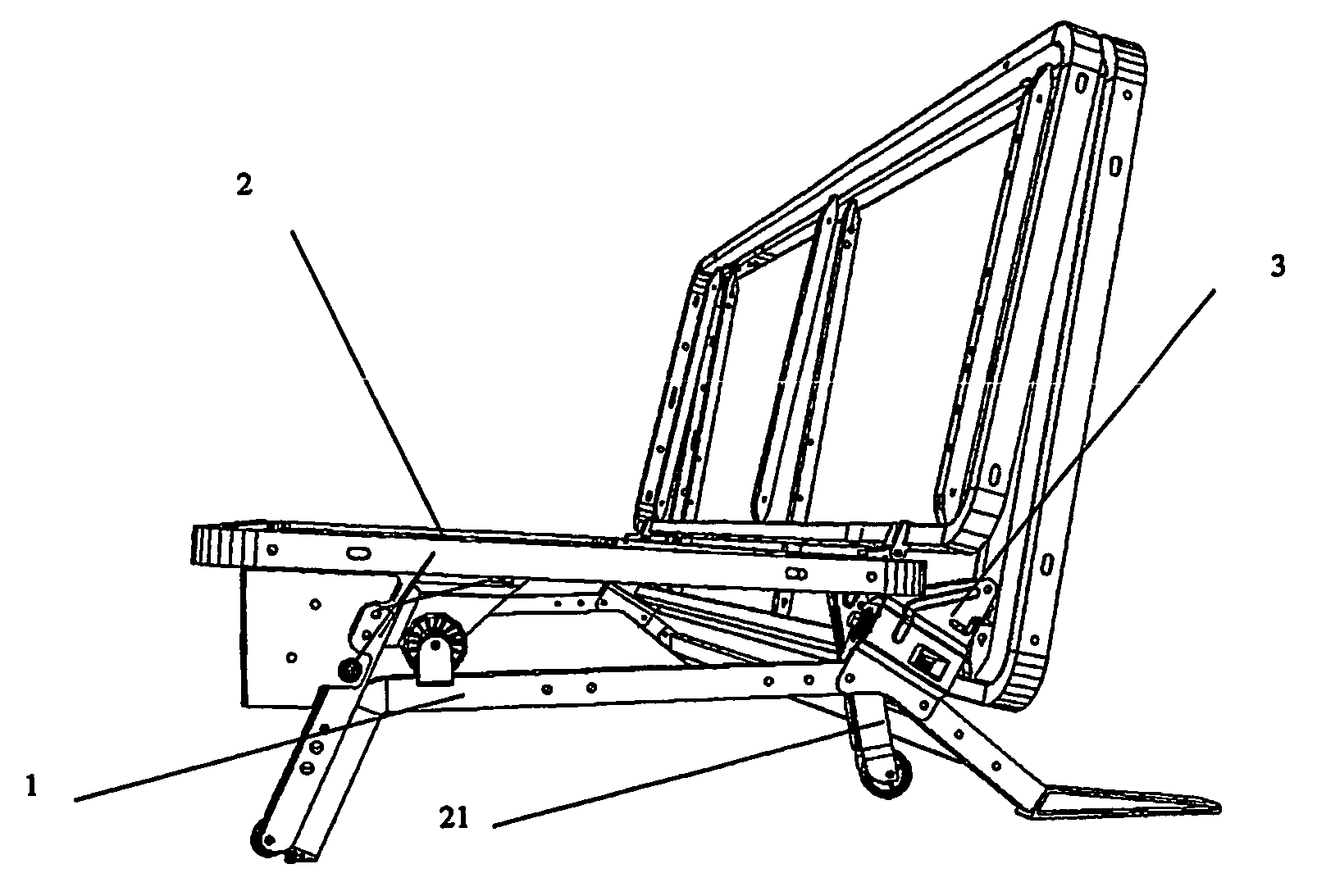

[0009]FIG. 1 is the sofa structure according to the invention;

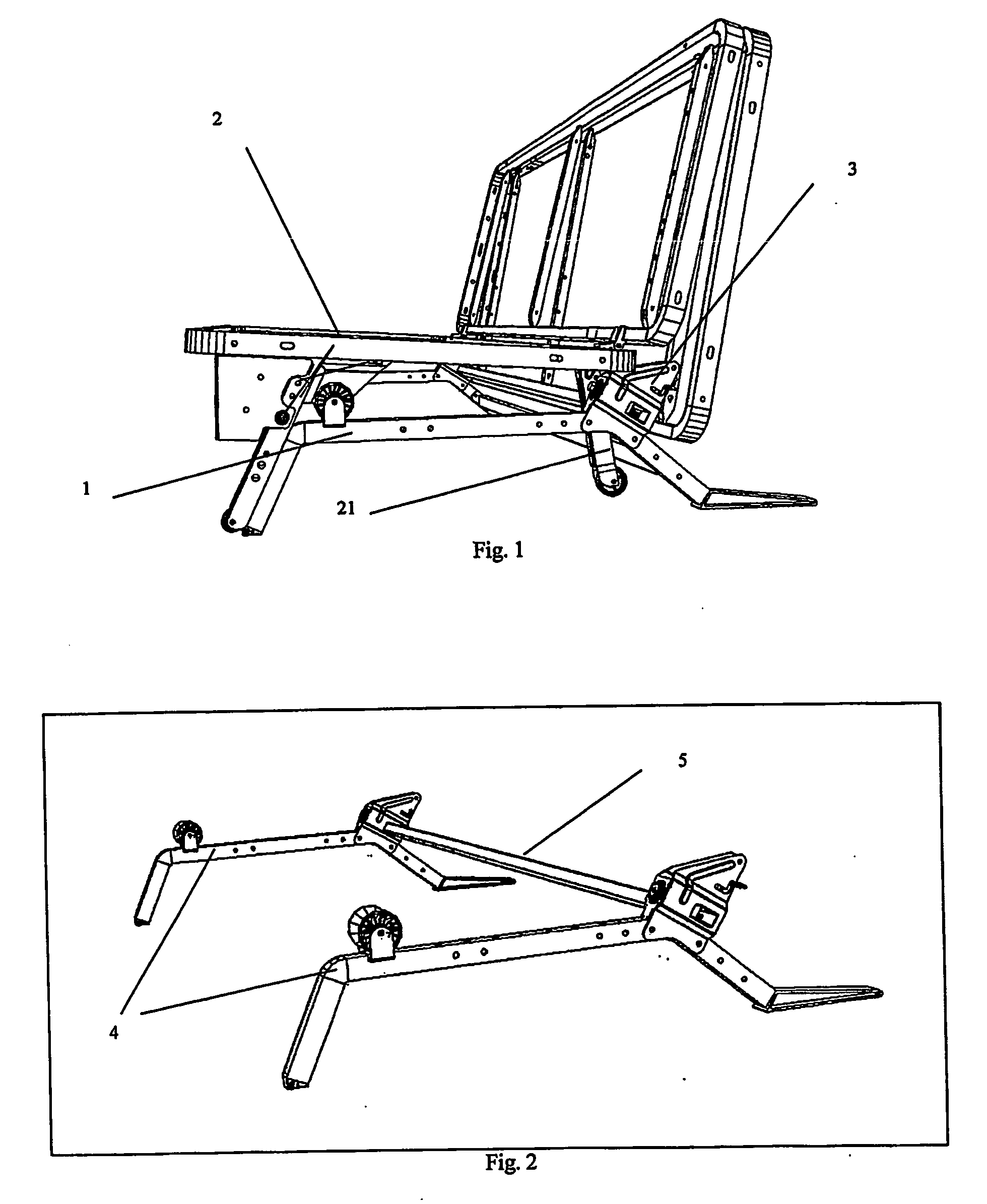

[0010]FIG. 2 shows the base structure;

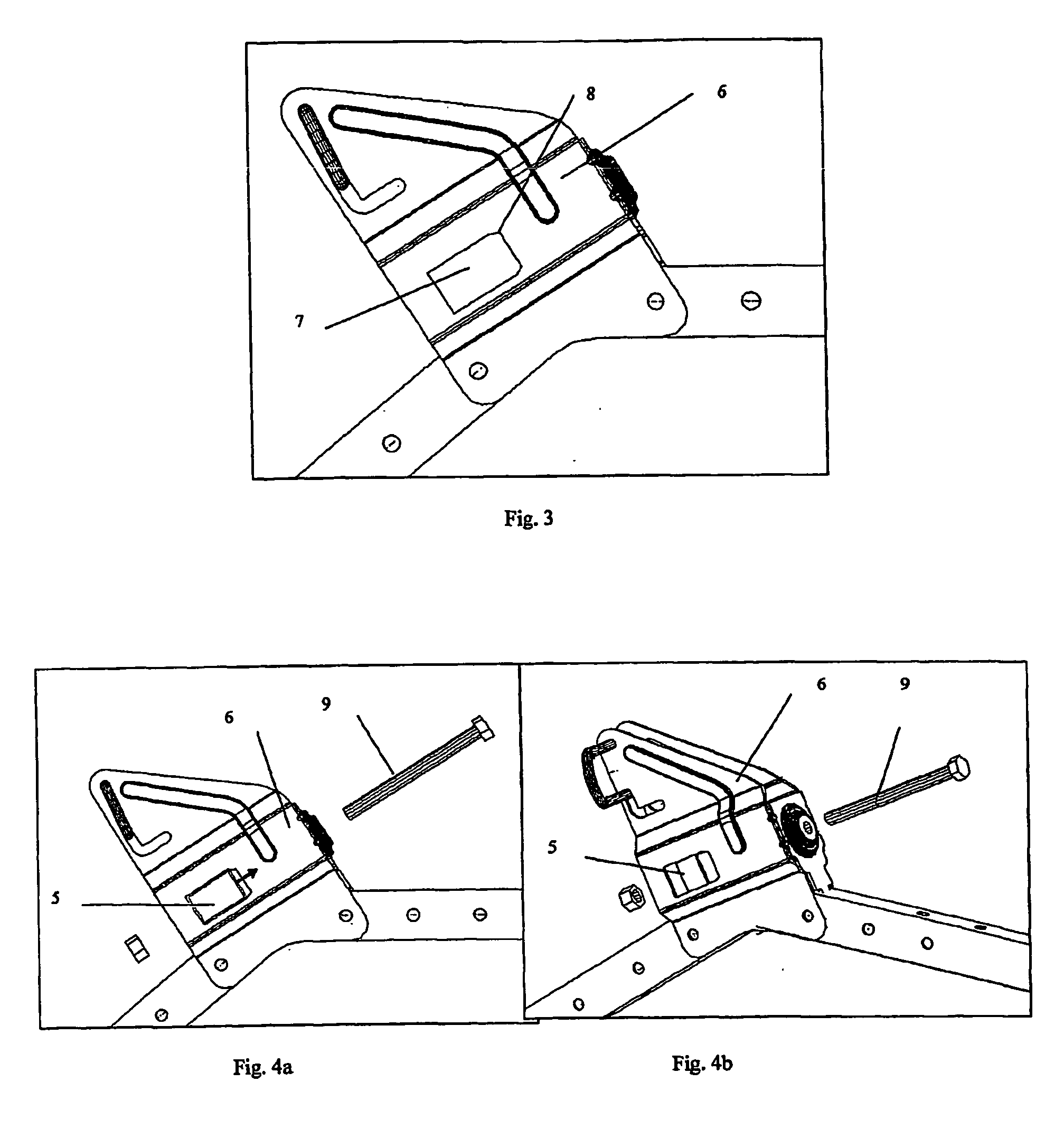

[0011]FIGS. 3 and 4 show a detail of the plate called “hinge”, respectively;

[0012]FIG. 5 shows the hinge between plate and frame;

[0013]FIG. 6 shows the detail of the shaped pin;

[0014]FIG. 7 shows the coupling between cam and roll;

[0015]FIG. 8 shows the front leg of the structure;

[0016]FIG. 9 shows the fastening of the front leg;

[0017]FIG. 10 shows a detail of the second fixation plate.

[0018]As already mentioned, the main purpose of the invention is to reduce as much as possible the clearance of the sofa base structure (1). FIG. 2 shows the sofa base structure that supports the hinged frames in the bed and sofa configurations, and comprises two identical elements, called “small legs” (4), and a spacer (5). Such a spacer is a rectangular pipe, which constrains and lets the two “small legs” be parallel to each other. In FIG. 3 is shown t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com