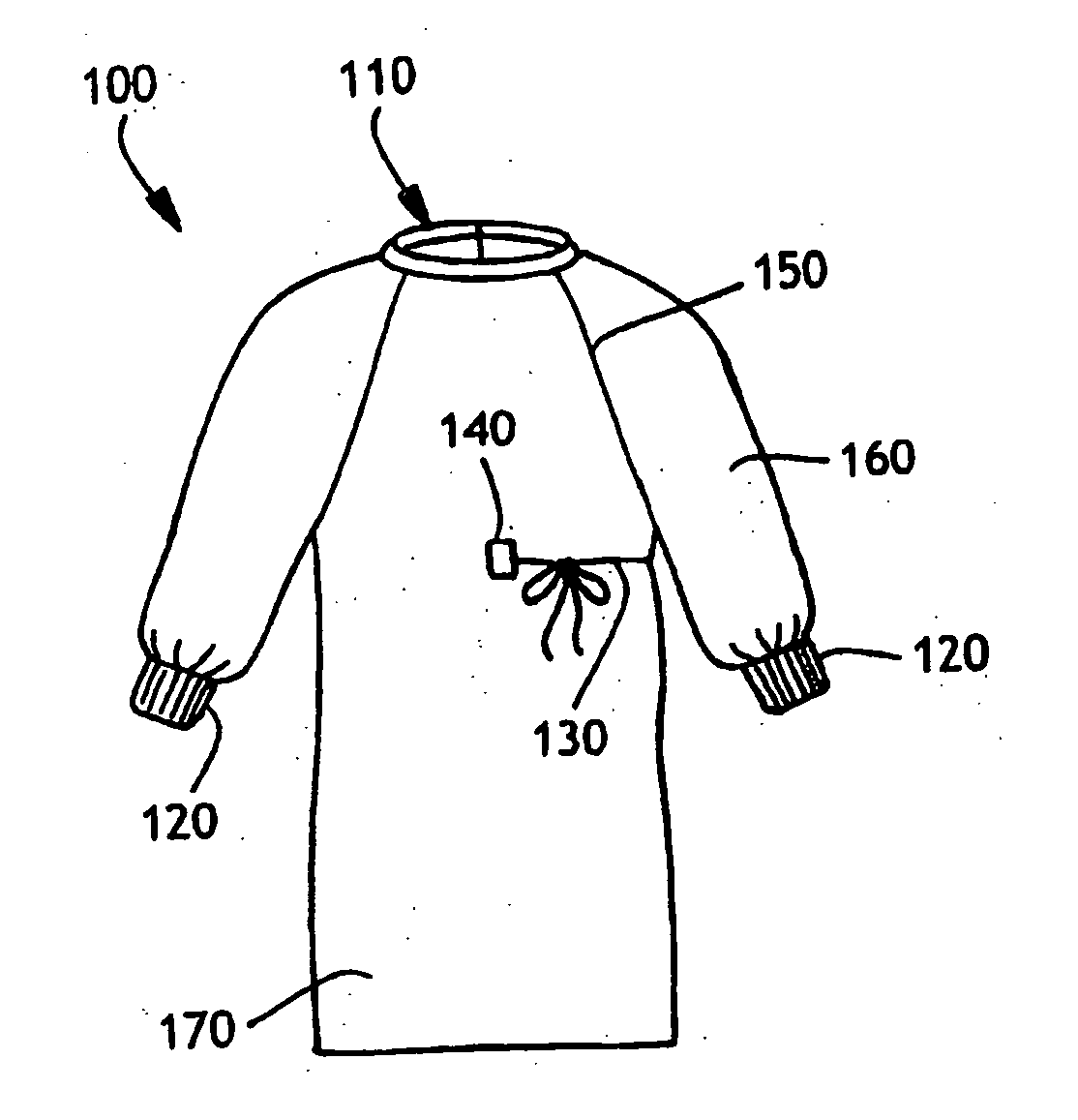

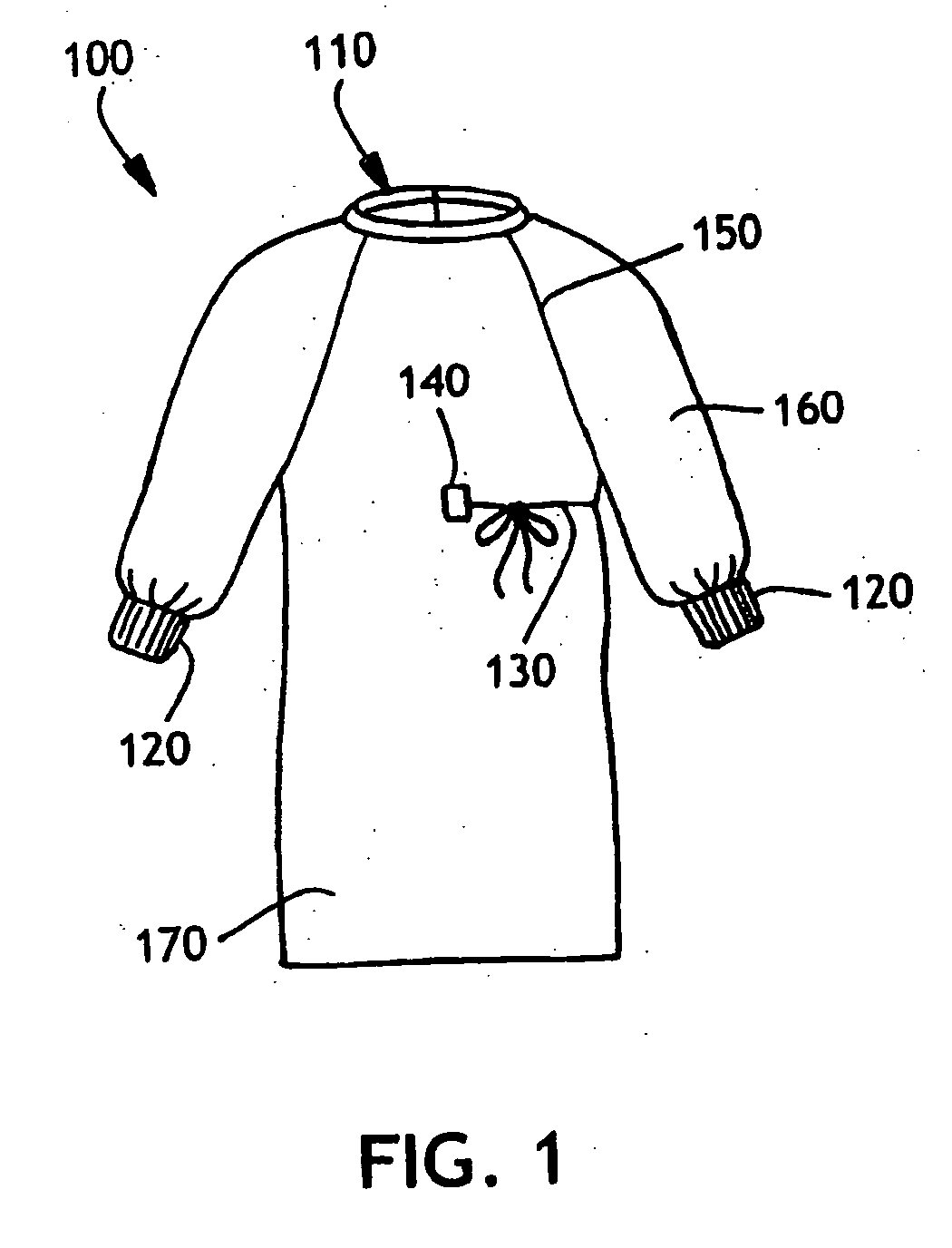

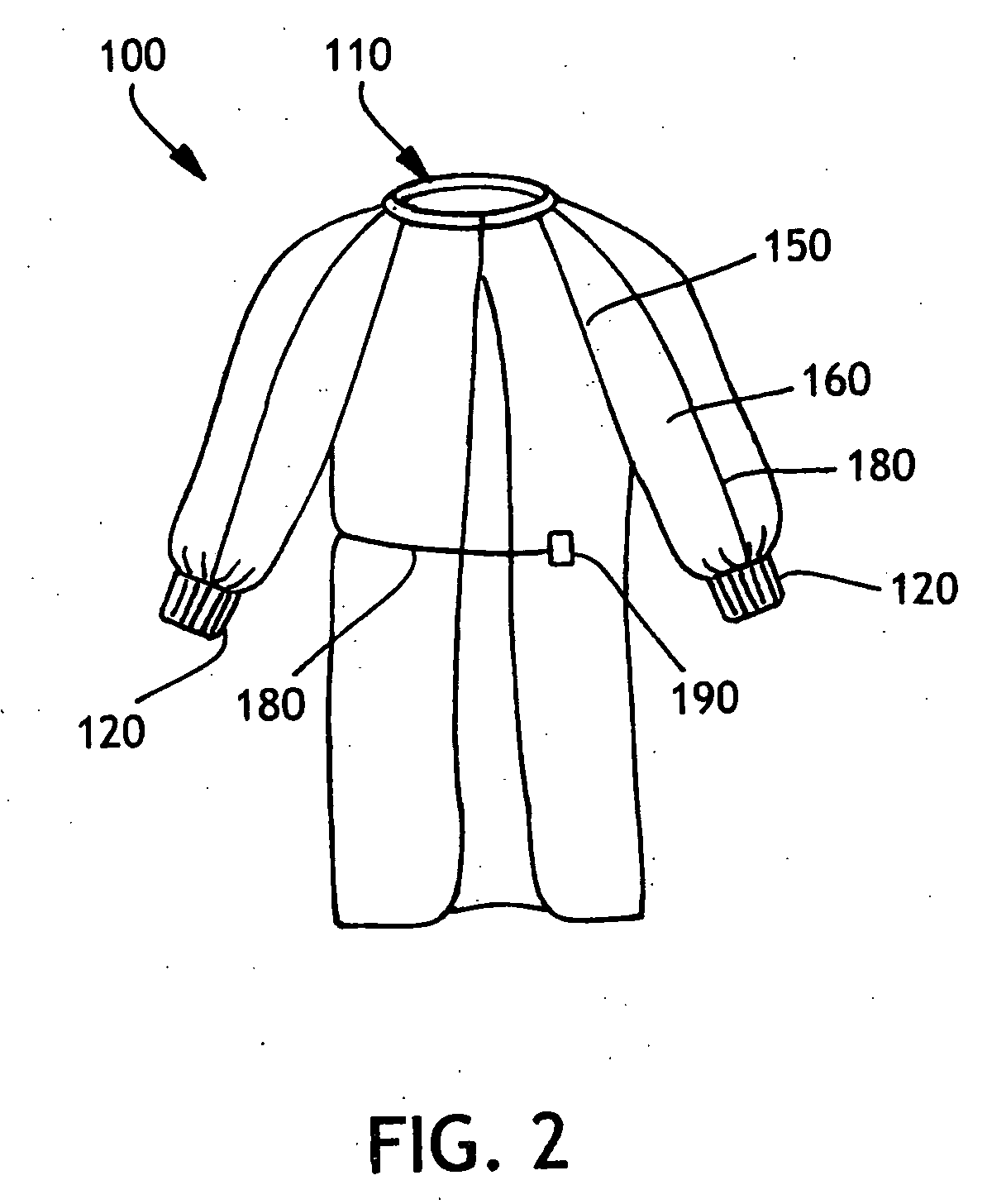

Surgical gown tie attachment

a surgical gown and tie technology, applied in the direction of protective garments, garments, applications, etc., can solve the problems of requiring costly laundering and sterilization procedures before reuse, requiring re-use, and supplying another potential source of contamination,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

Basic Ultra

[0045]A double folded SMS tie cord was bonded to an Ultra® surgical gown at a weld time of 0.175 seconds and a pressure of 65 psi using a point bond pattern. The bonded area was tested according to AATCC 127-1998. Twelve out of 12 samples failed.

example 2

Ultra with Fastape and PUB Bonding

[0046]A double folded SMS tie cord was bonded to an Ultral® surgical gown at a weld time of 0.175 seconds and a pressure of 65 psi using a PUB bond pattern with 25 percent bond area as described above. A 2.5 inch by 4 inch piece of Fastape® adhesive tape was placed below the tie cord bond site prior to bonding. The bonded area was tested according to AATCC 127-1998. Twelve out of 12 samples passed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com