Intelligent compounding equipment of medical surgical gown

A technology of composite equipment and surgical gowns, which is applied in the direction of sewing tools, etc., can solve the problems of low manufacturing efficiency and poor quality of medical surgical gowns, and no composite treatment of non-woven medical surgical gowns, so as to improve production efficiency and The effect of improving the quality of finished products, improving efficiency and improving the level of intelligence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be further described below in conjunction with the examples and drawings, but the embodiments of the present invention are not limited thereto.

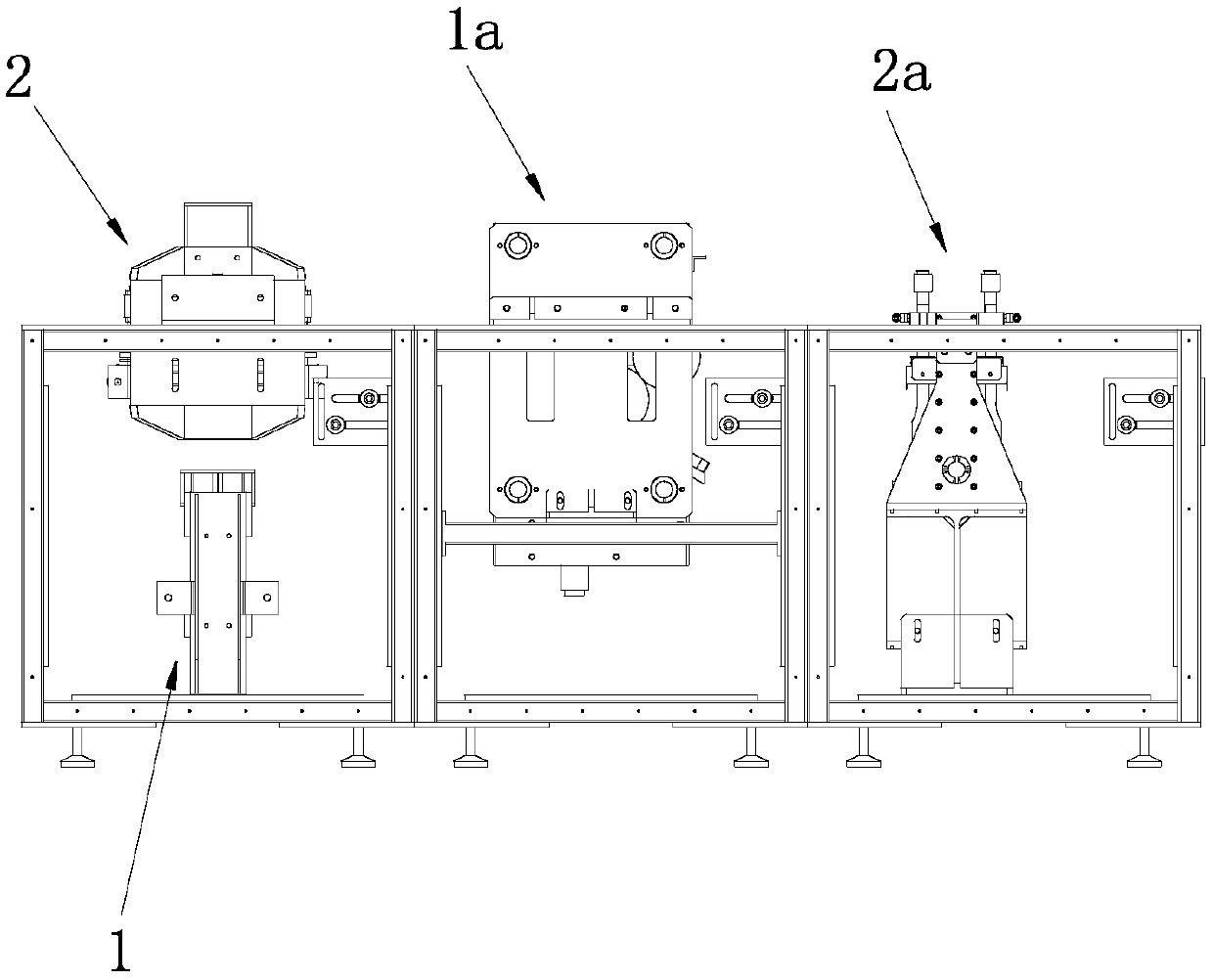

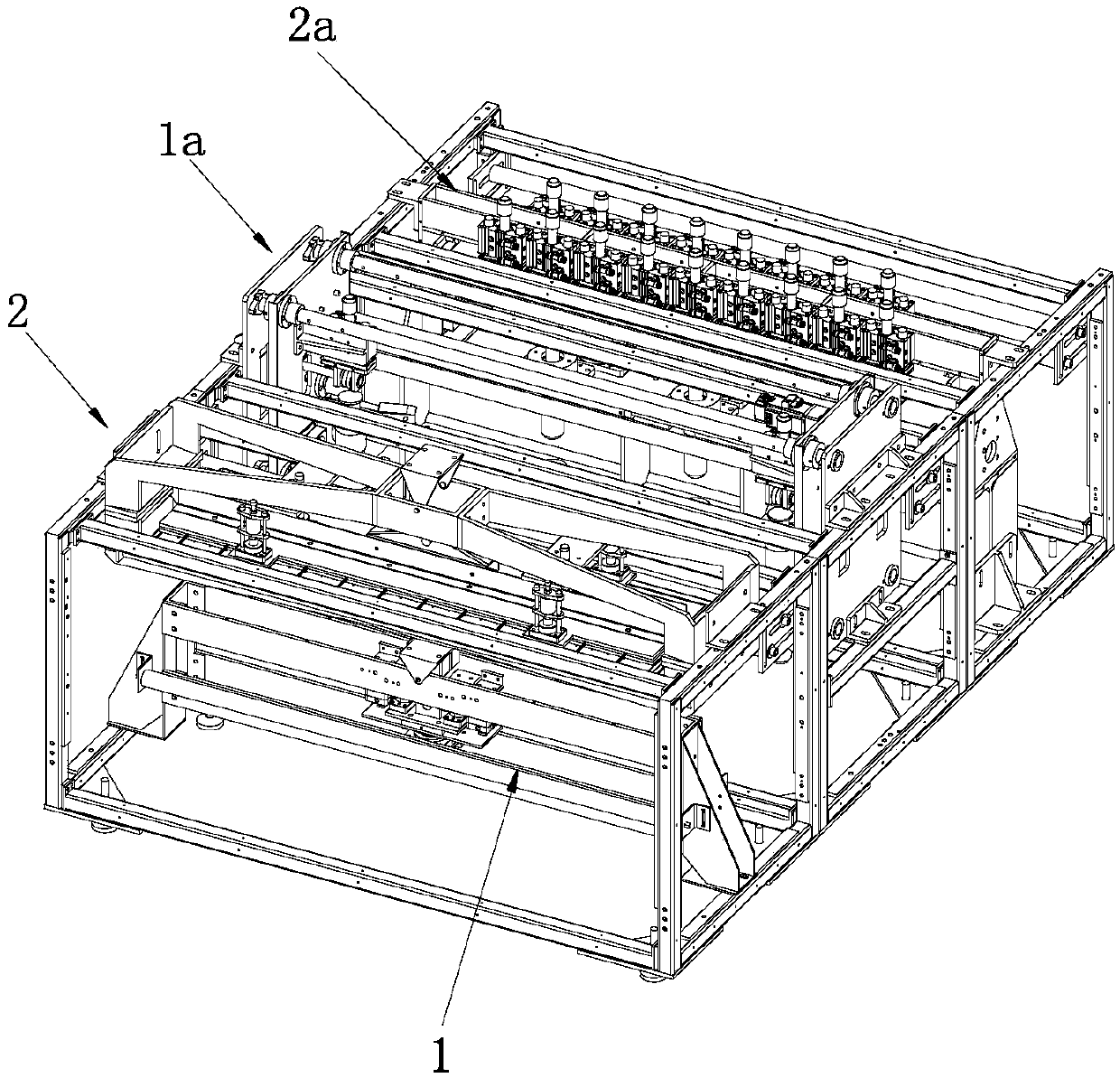

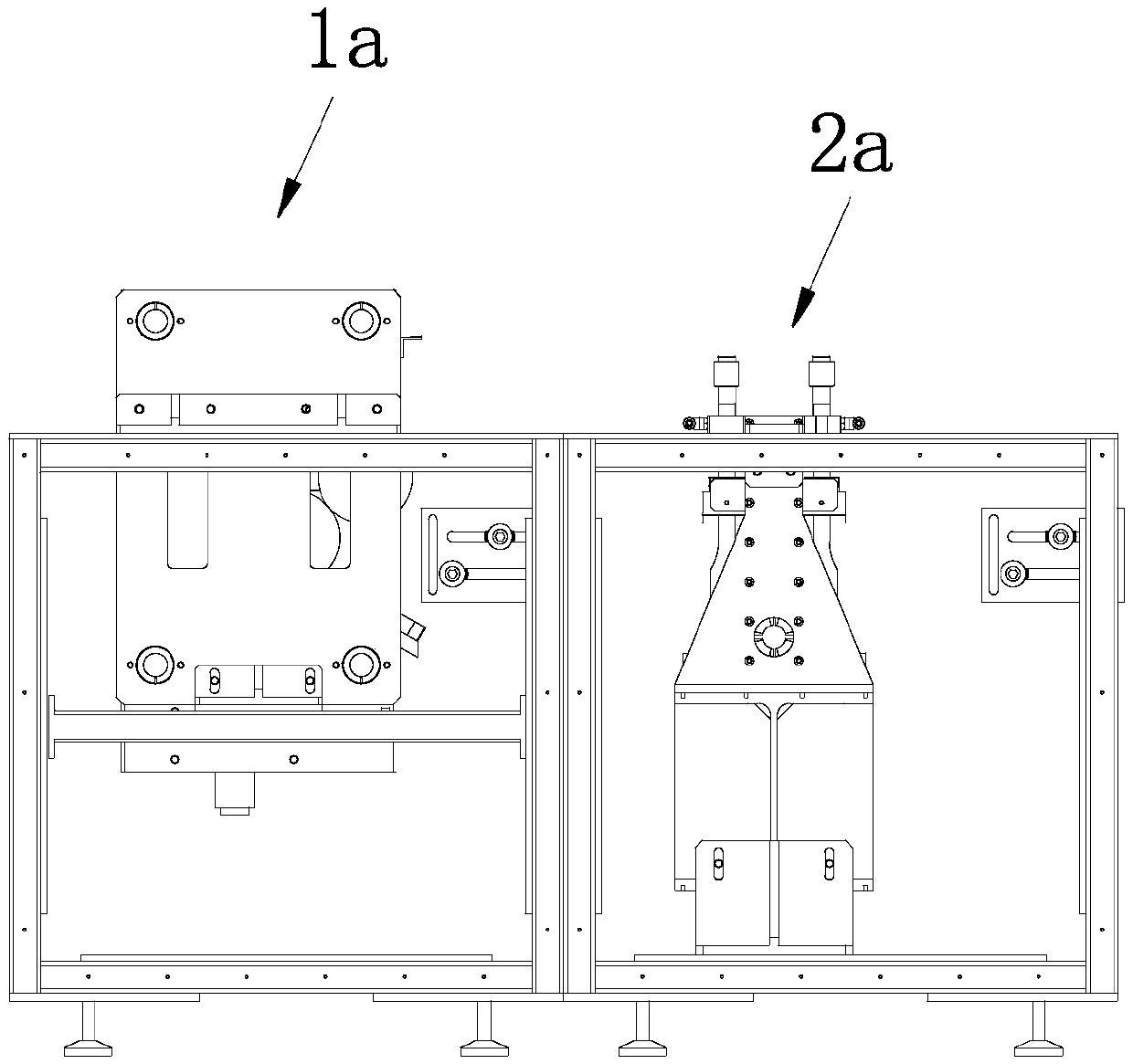

[0036] see Figure 1-Figure 11 , the intelligent composite equipment for medical surgical gowns in this embodiment includes a side welding module 1a, a middle welding module 2a, and a clamping and pulling mechanism for clamping the upper non-woven fabric and the lower non-woven fabric forward; along the upper non-woven fabric The moving direction of the woven fabric and the lower layer non-woven fabric, the middle welding module 2a is arranged in front of the side welding module 1a; wherein, the side welding module 1a includes two oppositely arranged rolling welding mechanisms 3a, each rolling The welding mechanism 3a all includes a welding head 13a, a pressing wheel 12a arranged above the welding head 13a, a side pressing drive mechanism 11a for driving the pressing wheel 12a to move vertically, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com