Packaging Bag with Tearing Aid

a technology of tearing aid and packaging bag, which is applied in the field of packaging bags, can solve the problems of difficult to implement in industrial mass production, the difficulty of starting the tear at the beginning of the weakened line, and the inability to tear in the desired region of most materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

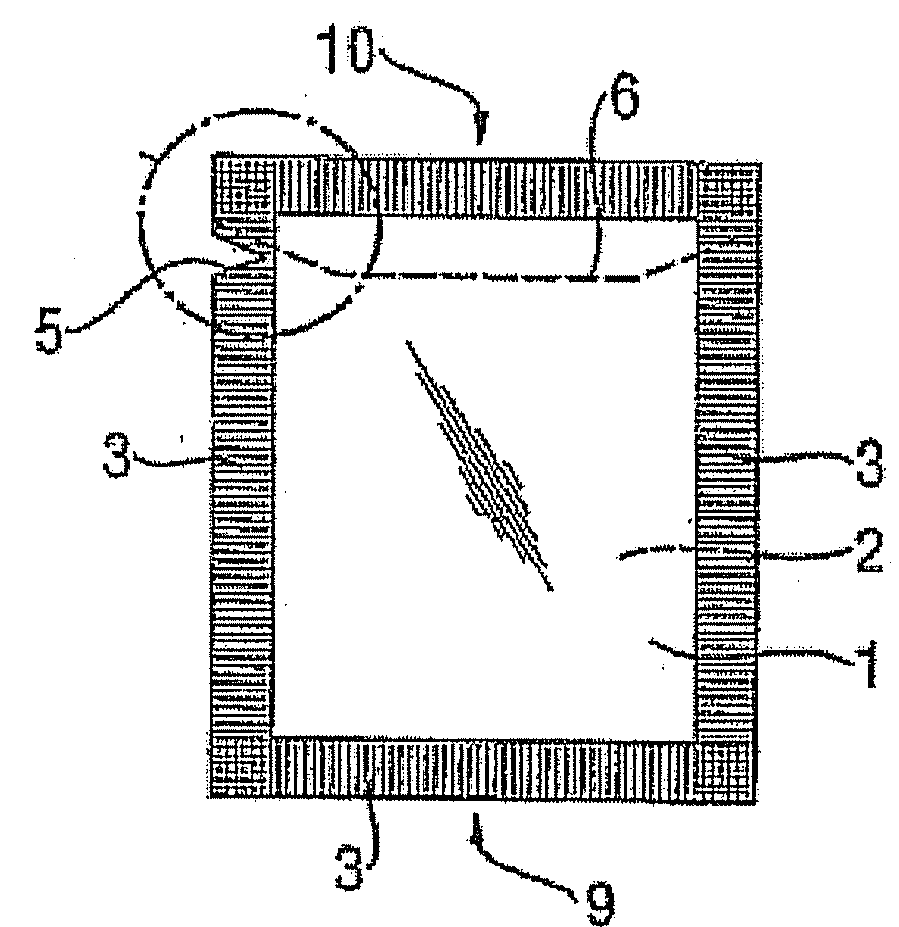

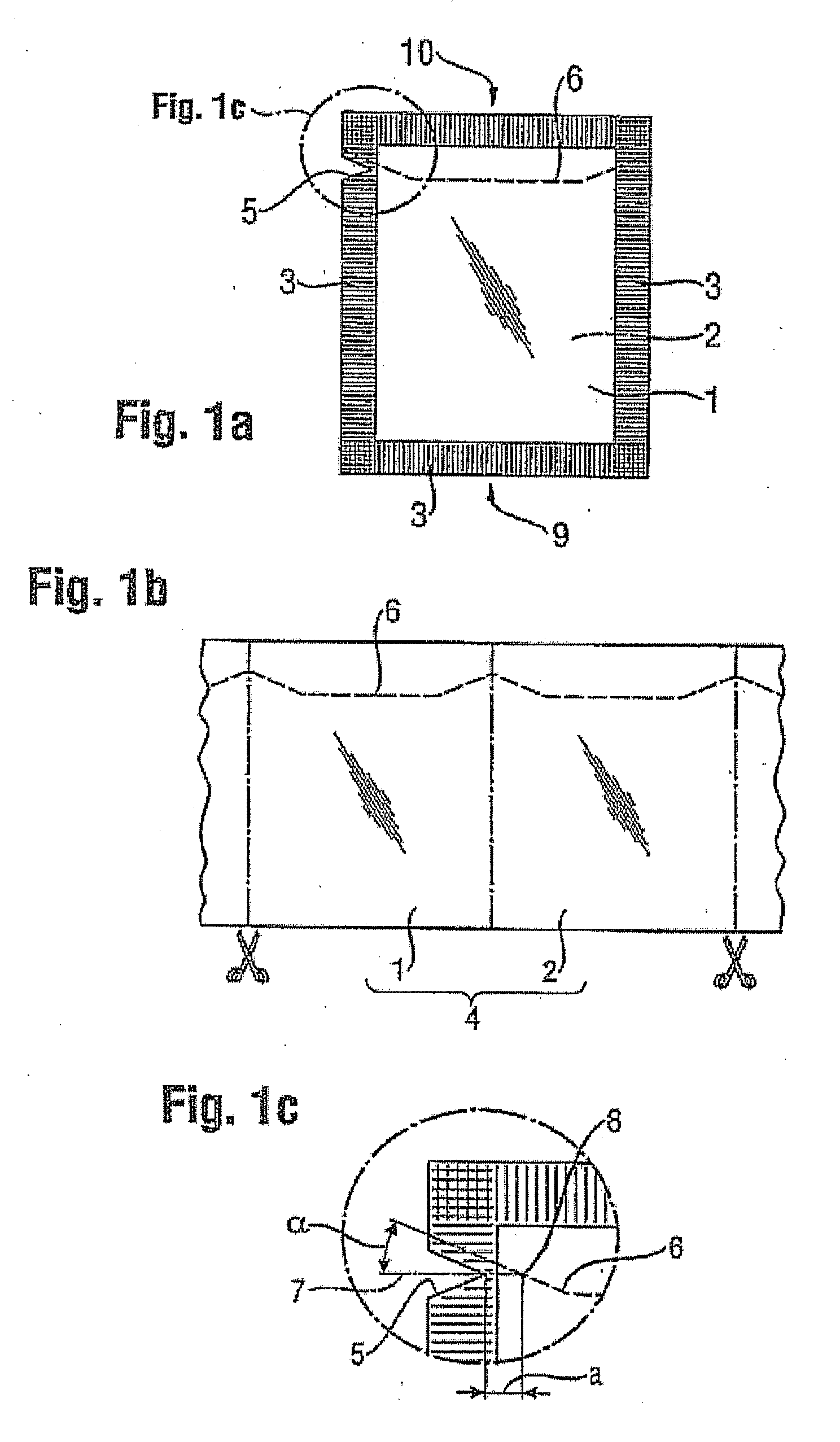

[0037]In FIG. 1a, a packaging bag according to the invention is shown in top plan view onto the front 1. The front 1 and the back 2, lying behind the front, have a rectangular shape and are connected to each other by means of a peripheral joint edge 3.

[0038]A blank 4 for this packaging bag, shown in FIG. 1b, is advantageously cut to length from a web of packaging material and has twice the width of the packaging bag. Through folding along the center line, the front 1 and the back 2 are placed so that one overlaps the other. The crease formed by the fold forms one of the two side edges. Connecting the other side edge and the bottom edge would be sufficient to create a packaging bag that can be filled. To achieve an overall symmetric impression or to be able to adequately grip the packaging bag peripherally, however, as a rule the edge region along the crease is also formed as a joint edge 3.

[0039]It is clear to someone skilled in the art that the blank 4 can also be shaped in such a ...

second embodiment

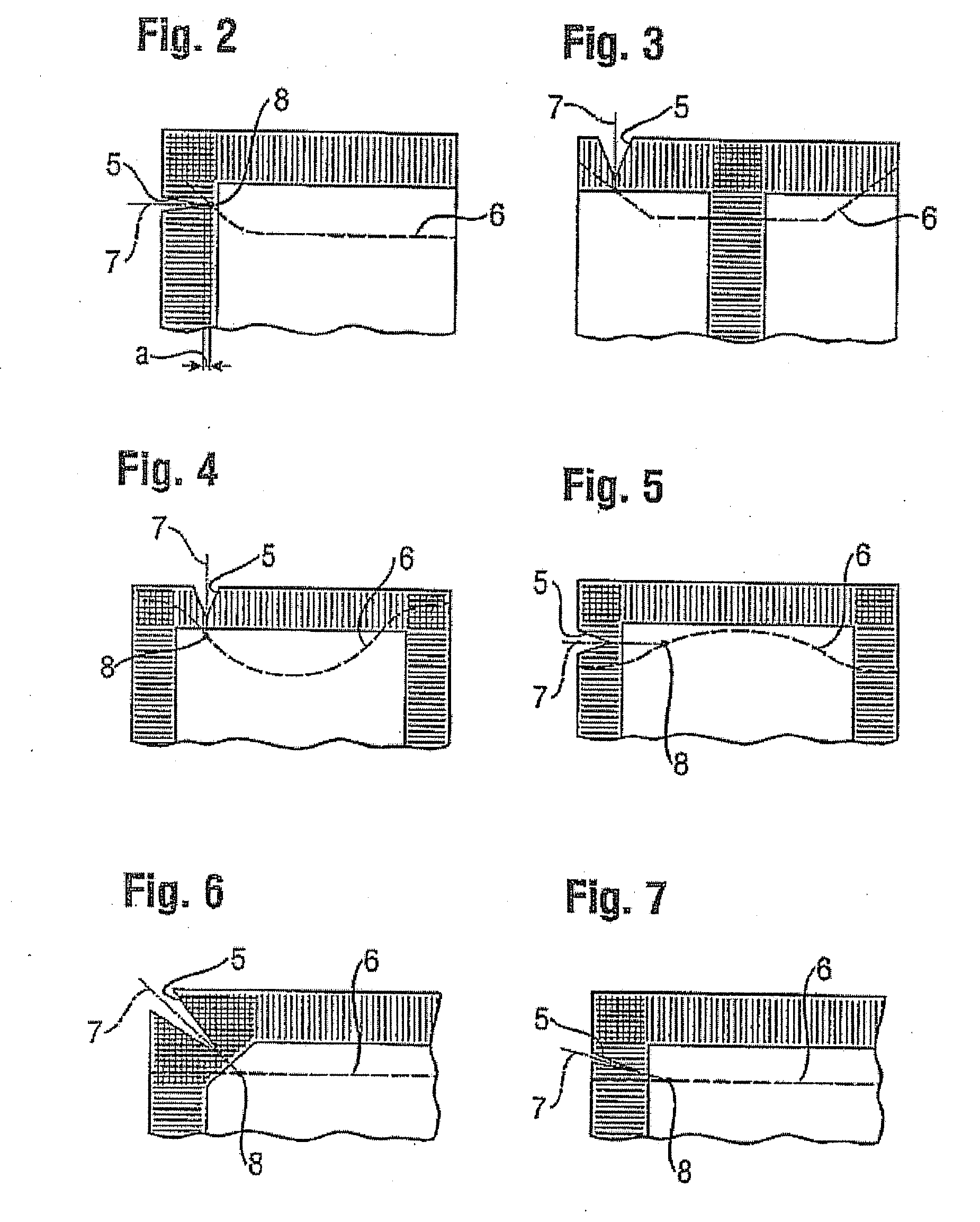

[0068]In a second embodiment shown in FIG. 2, the distance “a” is reduced in order to increase the reliability that an introduced tear actually intersects the weakened lines 6 and does not run away from these lines in an uncontrolled way. The intersection point 8 still lies within the joint edge 3. This has the effect that the guidance of the progressing tear still starts within the joint edge 3. Instead of an abrupt change in direction according to FIG. 1a, the line layout of the weakened line 6 has a continuous change in angle, due to the rounding of the angled line layout.

third embodiment

[0069]Like all of the embodiments described below, the third embodiment shown in FIG. 3 differs from the two aforementioned embodiments in that the opening notch 5 is not formed within the lower bag part 9, but instead within the upper bag part 10.

[0070]This has the advantage that a tear that progresses from the notch tip of the opening notch 5 intersects each of weakened lines 6 completely independently of the distance a.

[0071]In this third embodiment, the lateral edge regions are not formed as a joint edge 3, but instead are delimited exclusively by creases. Here, the packaging bag is closed across its length, as shown, on the back 2. The opening notch 5 is located in the joint edge 3 bordering the upper edge of the packaging bag.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tear angle | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com