Strength training system with folding frame

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

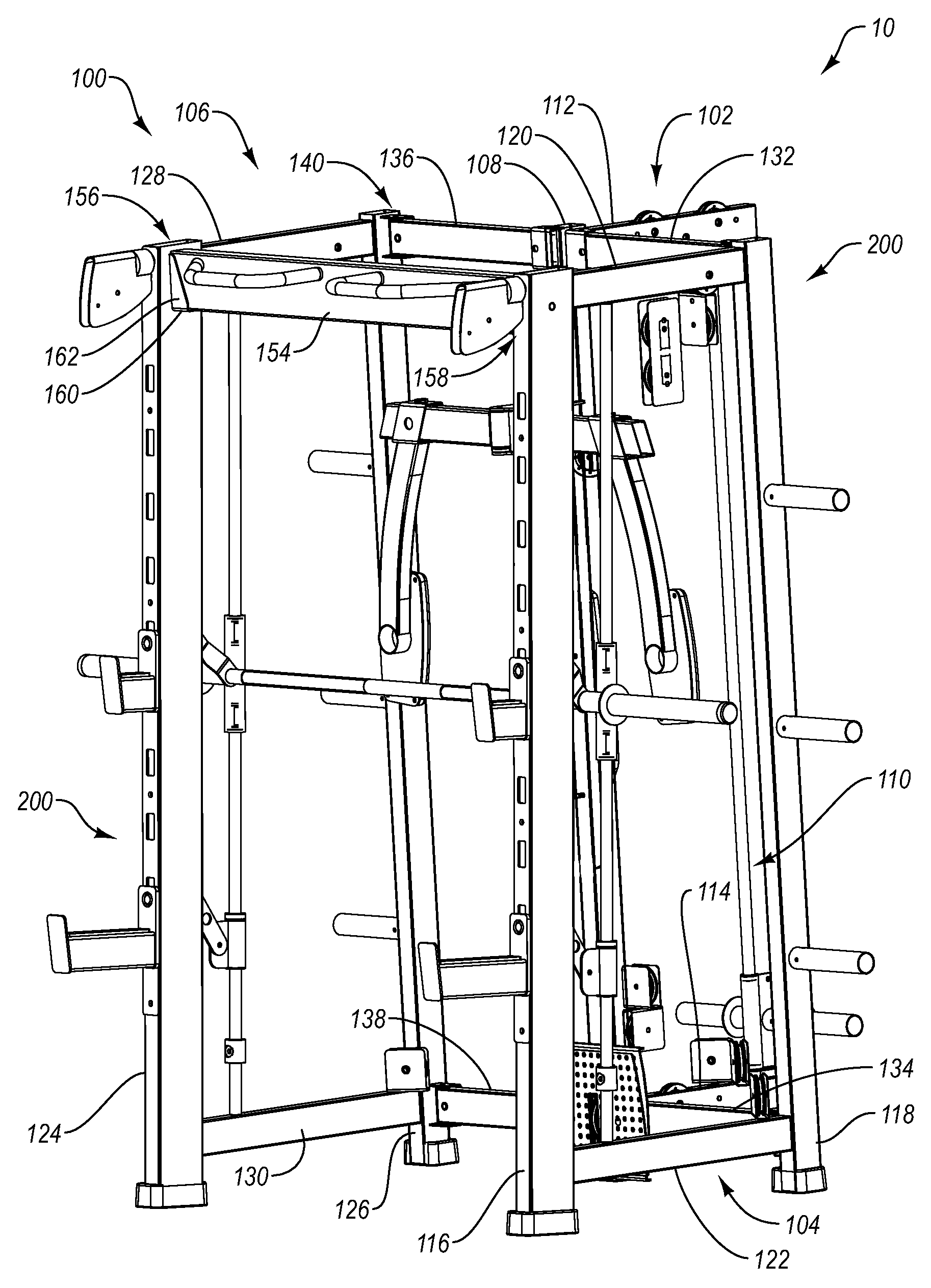

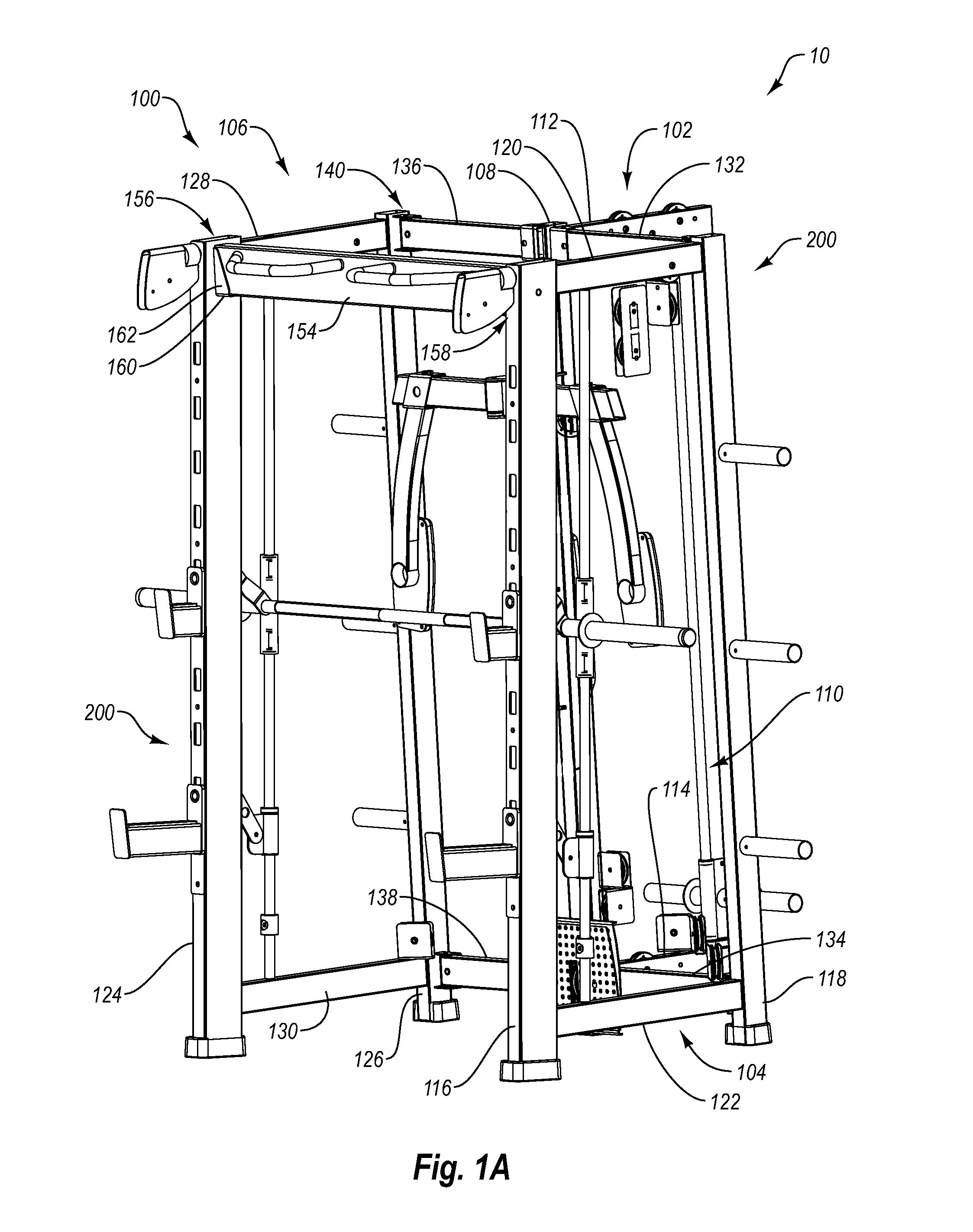

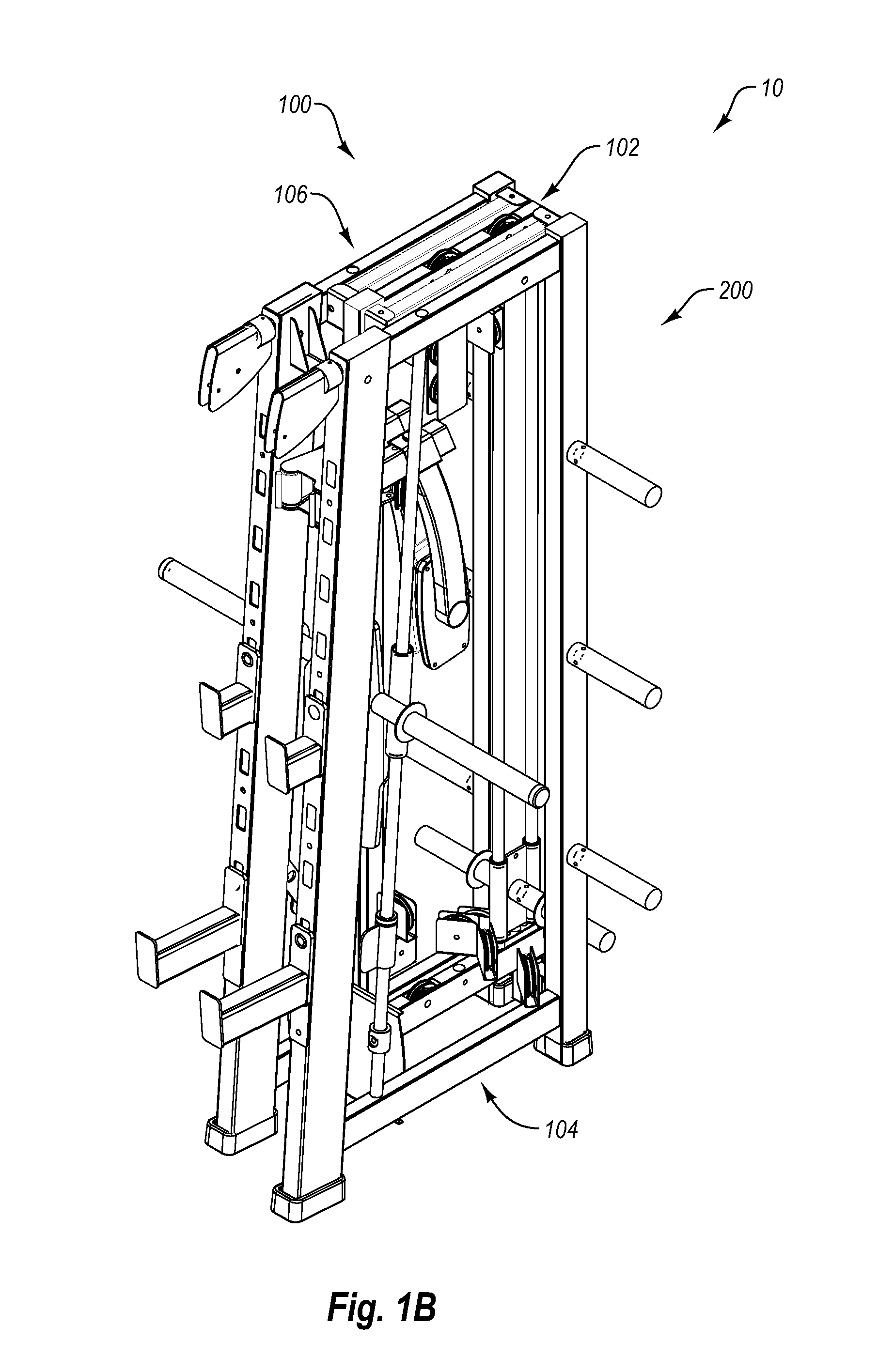

[0022]A folding frame assembly is provided herein, which may be part of a strength training system. The folding frame assembly is configured to be readily moved from a folded or collapsed position. In at least one example, the folding frame assembly includes several sub-frames that are coupled together with pivoting cross members. The pivoting cross members allow the sub-frames to be collapsed together while providing a stable platform for strength training equipment when the folding frame assembly is unfolded. Accordingly, the pivoting cross members allow the folding frame assembly to be nearly completely assembled, which may reduce the complexity of assembling the exercise system. Further, the configuration of the folding frame assembly allows the folding frame assembly to have a folded footprint that is at least about 70 percent less than the expanded footprint, such as at least about 80 percent less than the expanded footprint, e.g., about 85 percent less. Such a configuration m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com