Refuse Chute

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031]The present invention may be implemented in a variety of ways and the embodiments illustrated are to be considered only illustrative constructions.

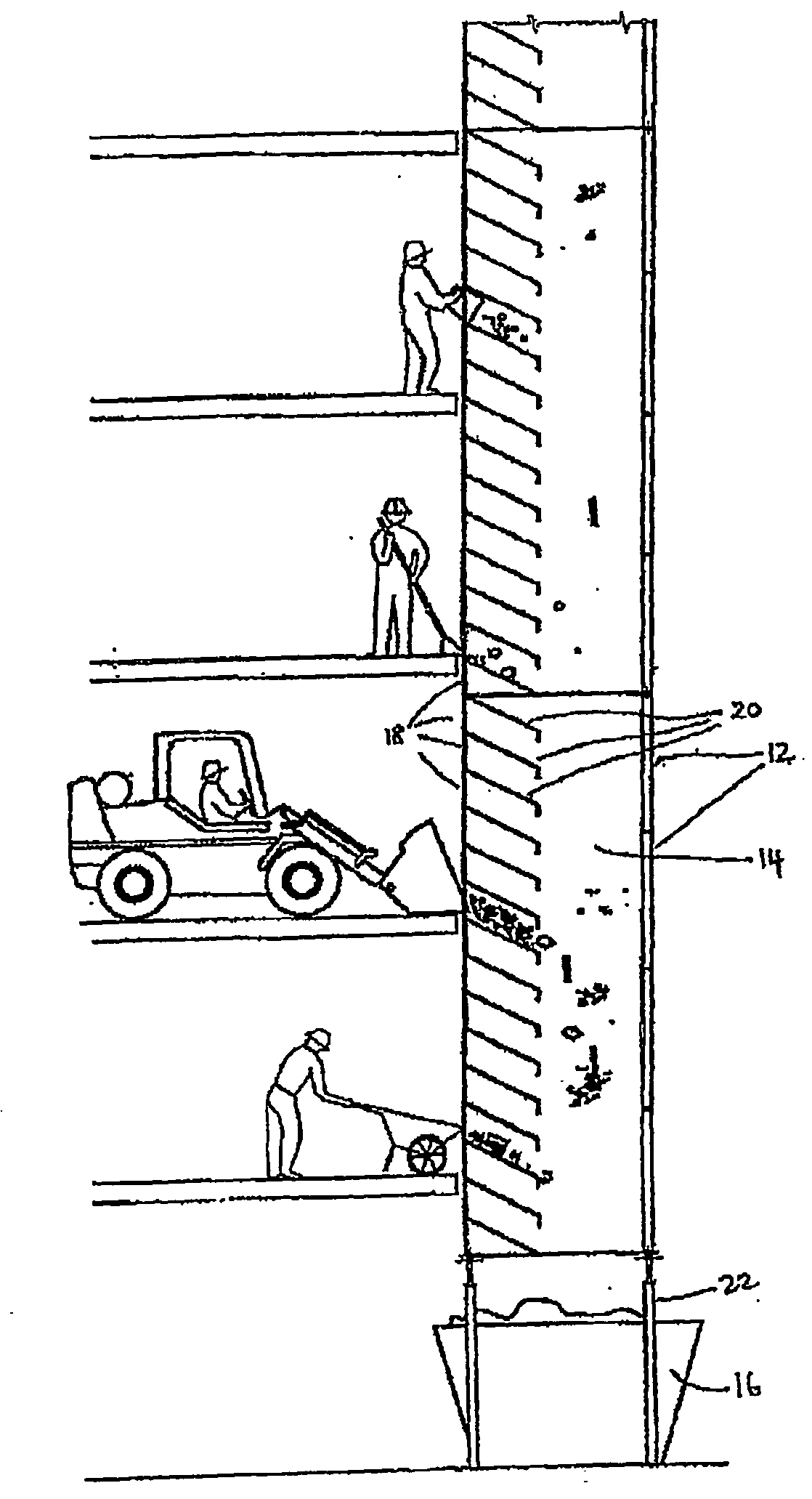

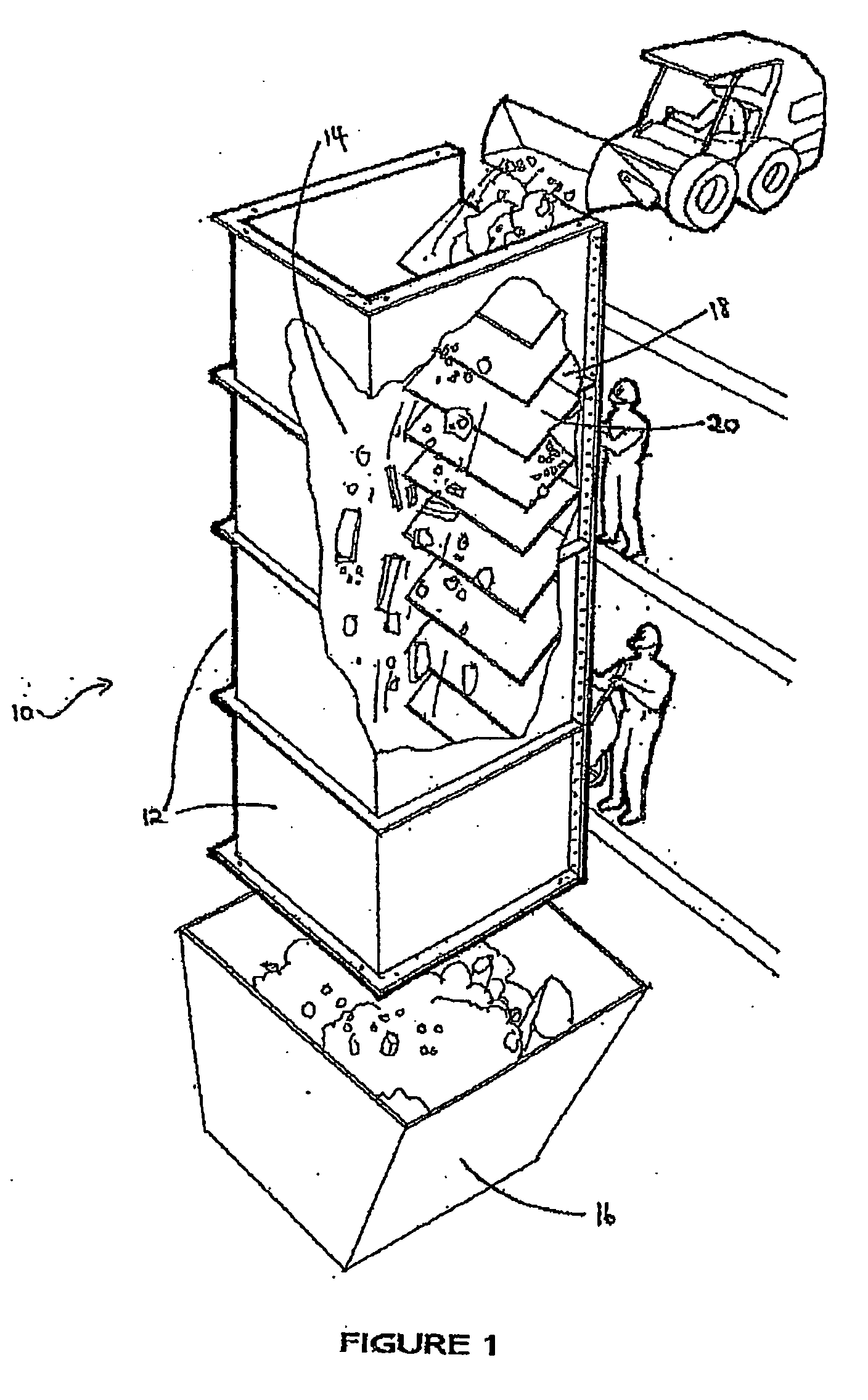

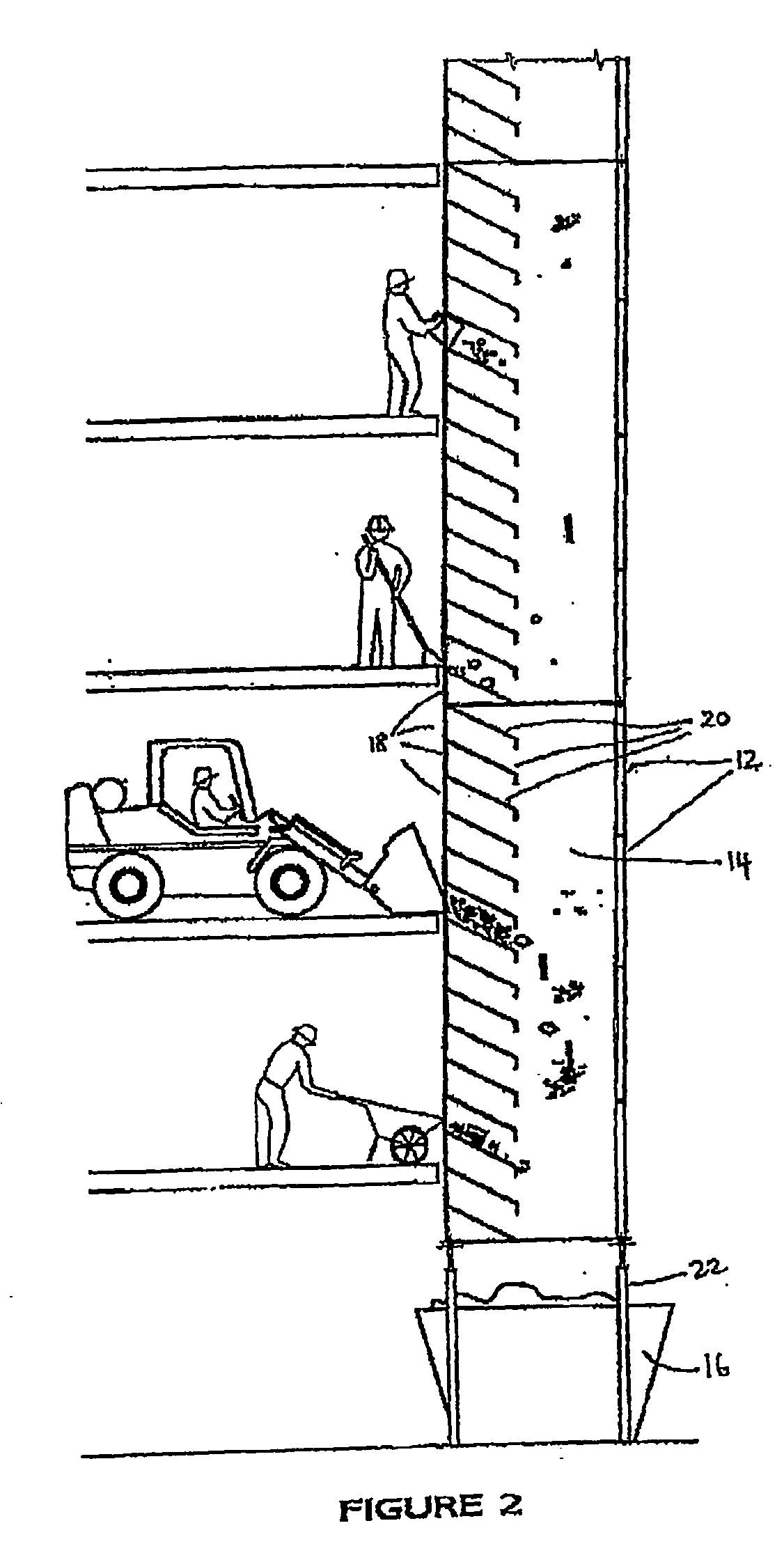

[0032]FIG. 1 is a schematic perspective view of the refuse chute 10. Refuse chute 10 is assembled from four identical chute sections 12. The chute sections 12 may be identical and stacked and secured together at the end faces, as shown, or be of some other configuration such as a nesting arrangement in which the chute sections are joined together through their side walls, ie similar to telescopically inserted sections. The chute sections 12 can be stacked as high as needed for the particular application. Different types of chute sections are known from, for example, GB 2,229,427 A, U.S. Pat. No. 3,627,090, and AU 682758, the contents of which are hereby incorporated by reference.

[0033]In this case, the chute sections 12 are of constant quadrilateral cross-section, made of steel sheets, and removably joined together at their end face...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com