Die for die casting and method of manufacturing cast product

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

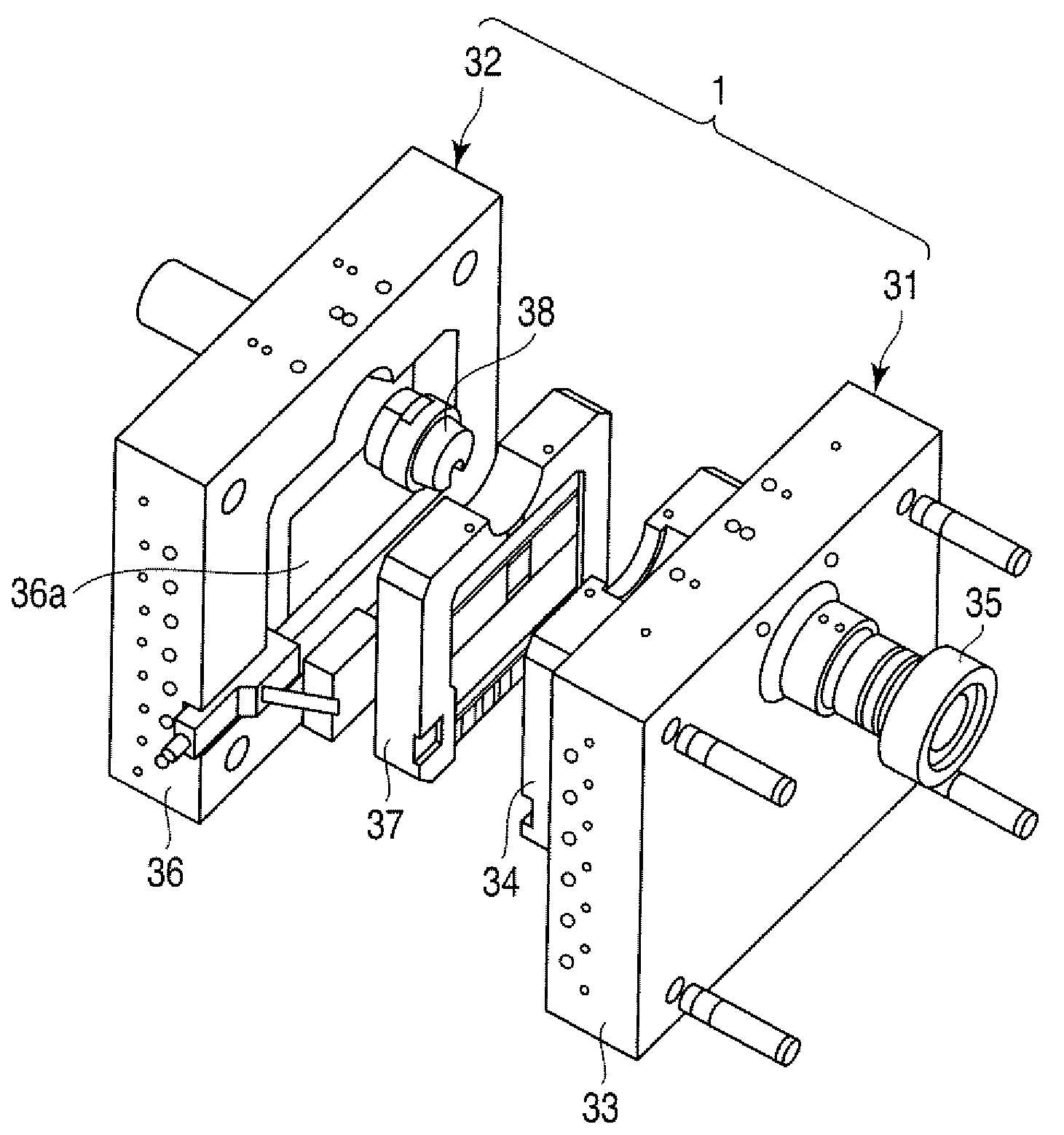

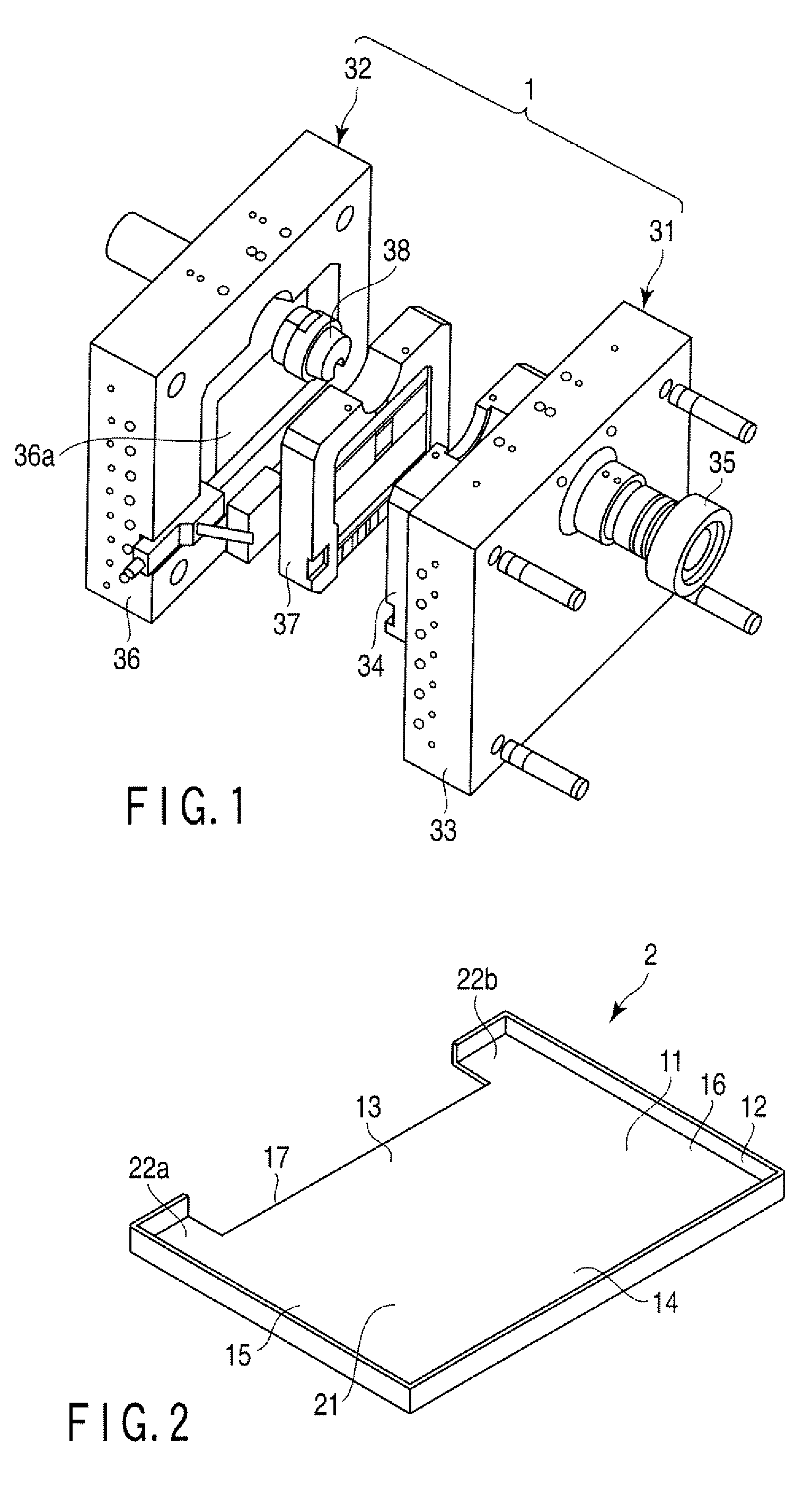

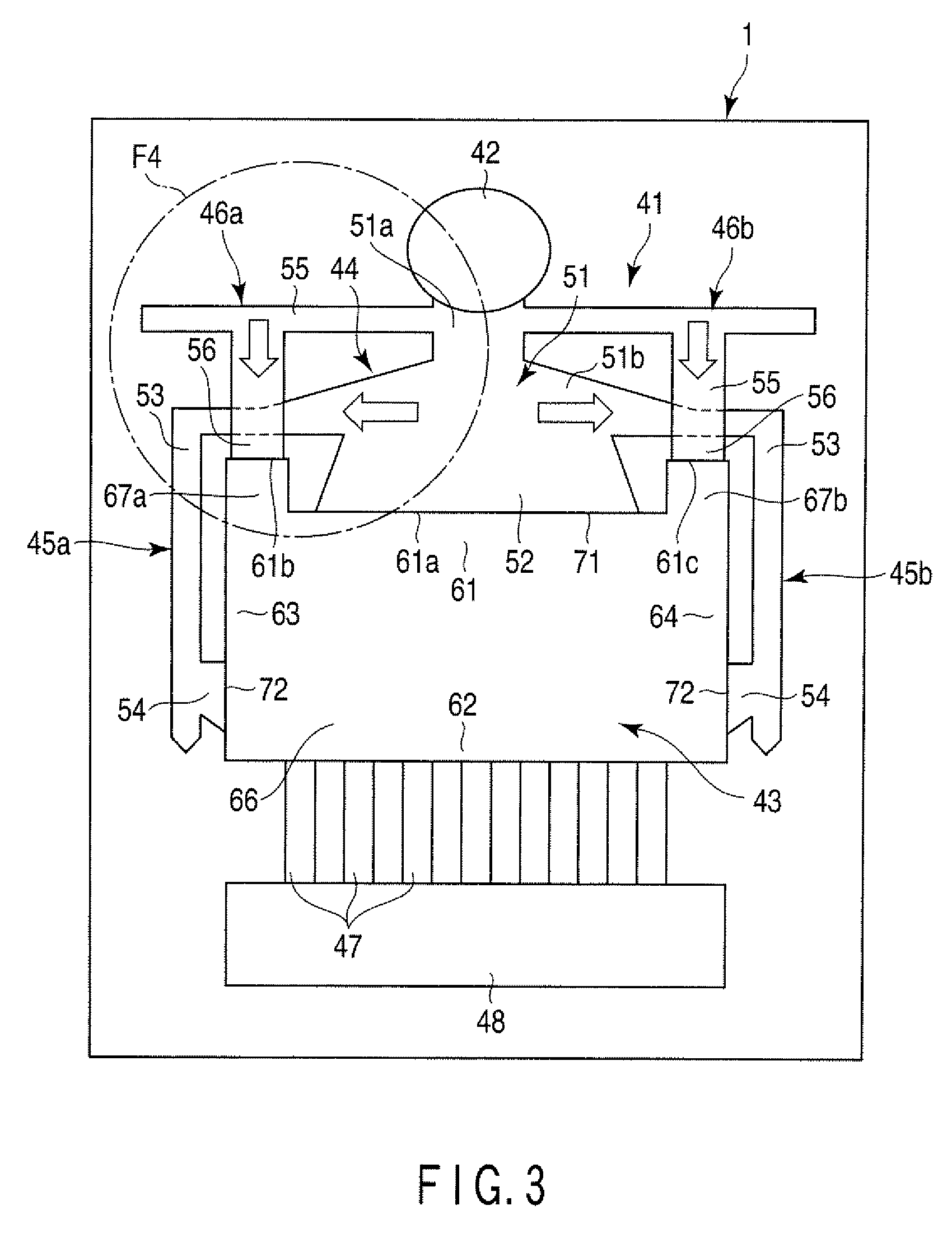

[0019]Various embodiments according to the invention will be described hereinafter with reference to the accompanying drawings. In general, according to one embodiment of the invention, a die for die casting comprises: a stationary die; and a movable die to be combined with the stationary die. When the movable die is combined with the stationary die, a biscuit section, a product section, a first runner, a first gate, a second runner, and a second gate are formed between the stationary die and the movable die. The biscuit section is a section into which molten metal is to be injected. The product section comprises a main product section, and a protrusion part which protrudes from the main product section toward a side of the biscuit section. The first runner is configured to guide the molten metal injected into the biscuit section toward the main product section. The first gate is provided between the first runner and the main product section at a position on a downstream side of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com