Side view light emitting diode package

a technology of light-emitting diodes and side views, which is applied in the direction of optics, optical elements, instruments, etc., can solve the problems of reducing the entire light quantity emitted out and degrading performance, so as to improve the beam angle characteristics of emission light, prevent a sidewall molding defect, and increase the light quantity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035]The present invention will now be described more fully hereinafter with reference to the accompanying drawings, in which preferred embodiments of the invention are shown.

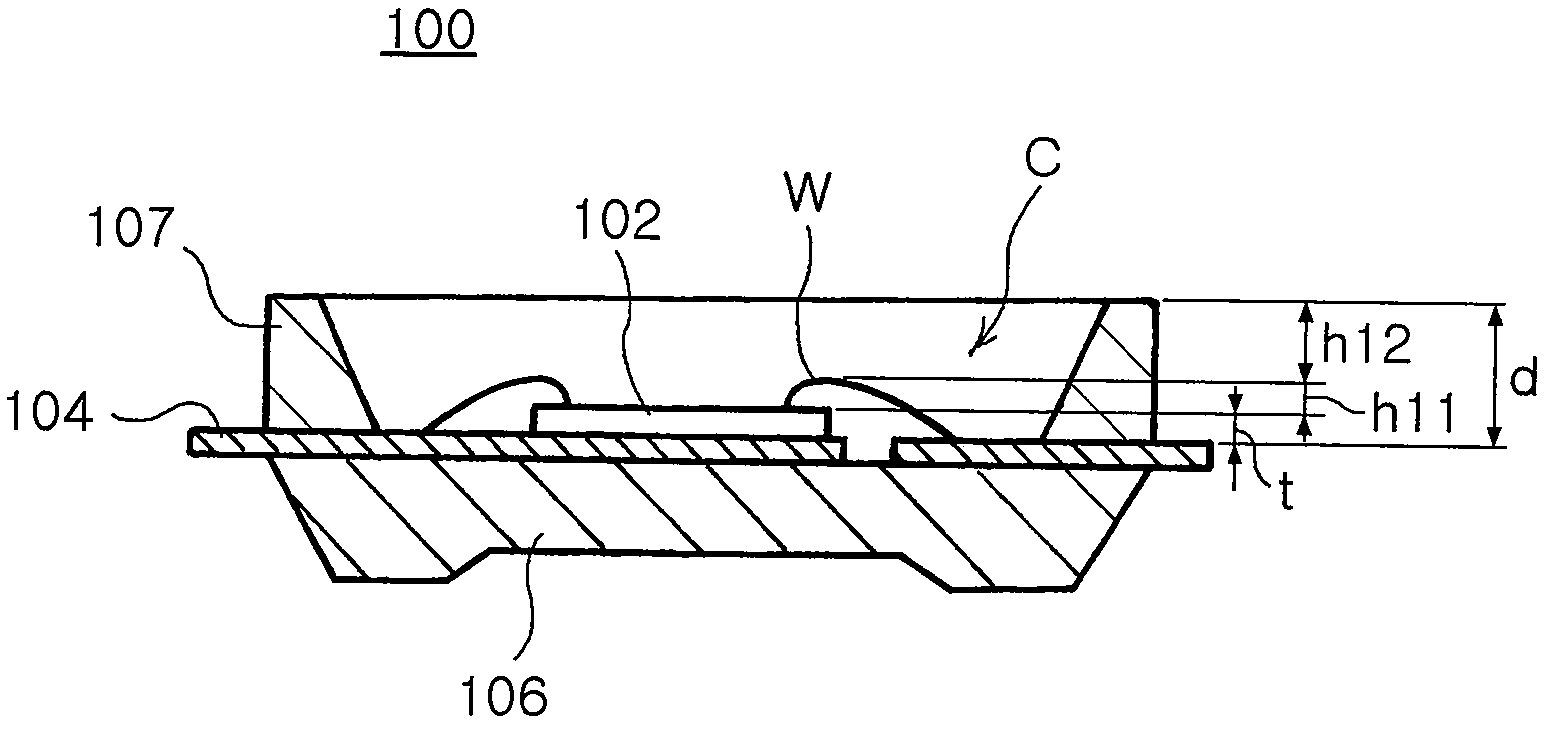

[0036]FIG. 6 is a cross-sectional view illustrating an LED package 100 according to an embodiment of the invention.

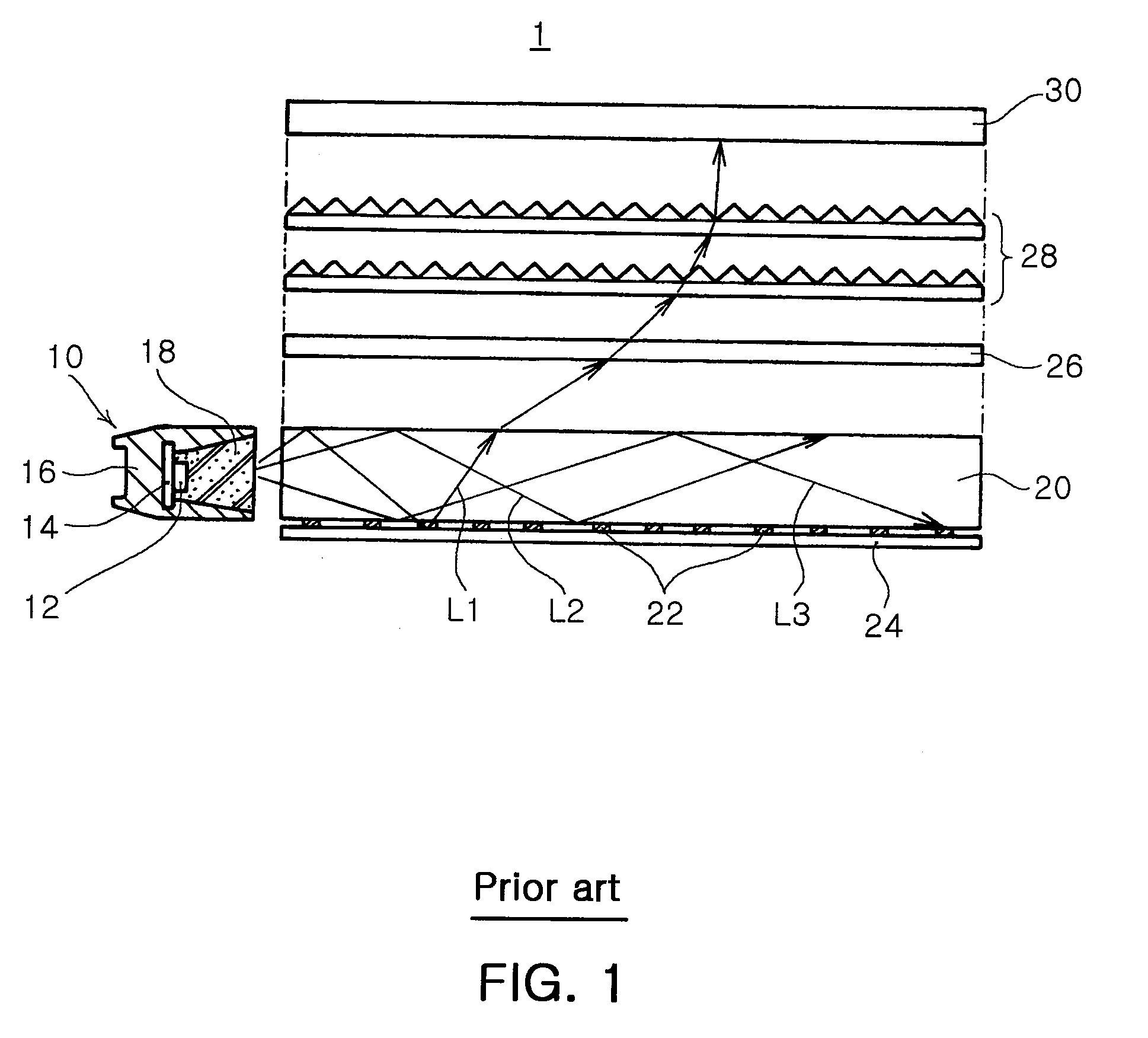

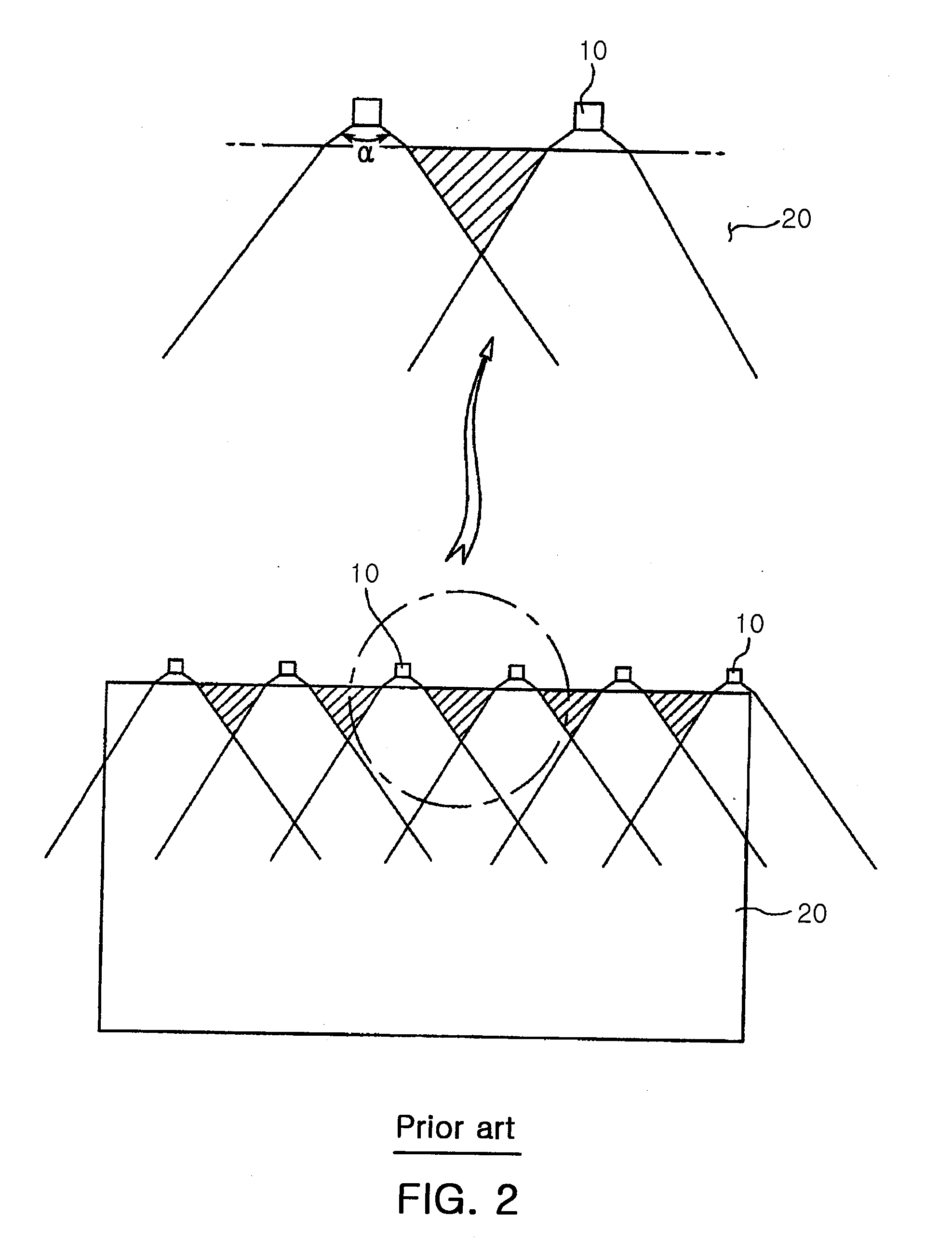

[0037]Referring to FIG. 6, the side view LED package 100 of the invention is applied to the backlight unit 1 as shown in FIG. 1. The LED package 100 includes an LED chip 102, first and second lead frames 104 for supplying power to the LED chip 102 seated thereon, a package body 106 injection-molded to hold the first and second lead frames 104 and an encapsulant 108 of a transparent resin filled in a cavity C of the package body 106 to encapsulate the LED chip 102.

[0038]The LED package 100 according to this embodiment of the invention has an improvement in the cavity C in order to improve light quantity and beam angle. The height of a sidewall of the LED package 100, that is, the depth d of the cav...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com