Prosthetic implant support structure

a technology of support structure and prosthesis, which is applied in the field of prosthetic devices, can solve the problems of loss of strong bone stock near the joint being replaced, cumbersome devices used to deliver bone grafts, and defects in bone adjacent to the joint, so as to facilitate bone ingrowth and attachment, and optimize the support of the implan

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

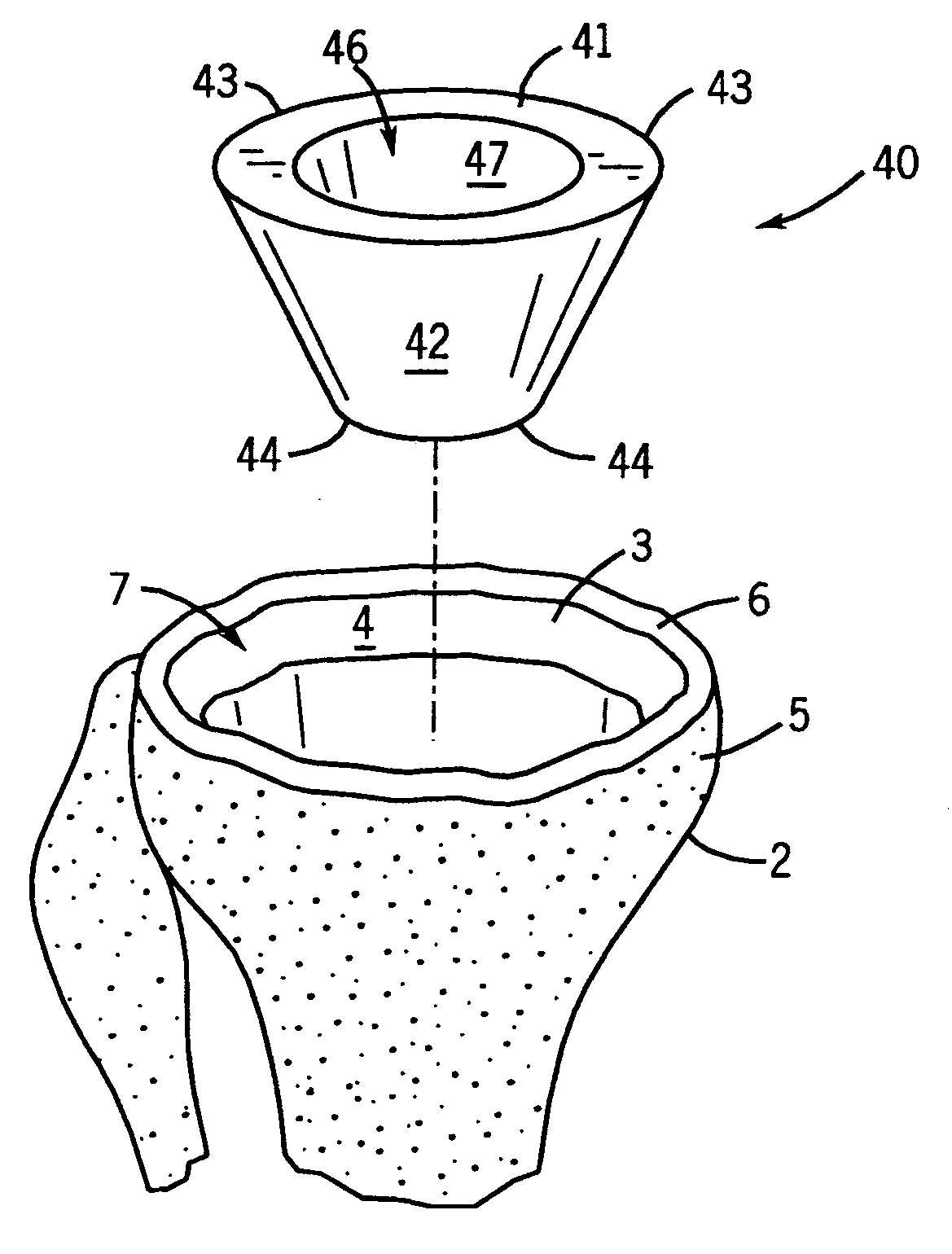

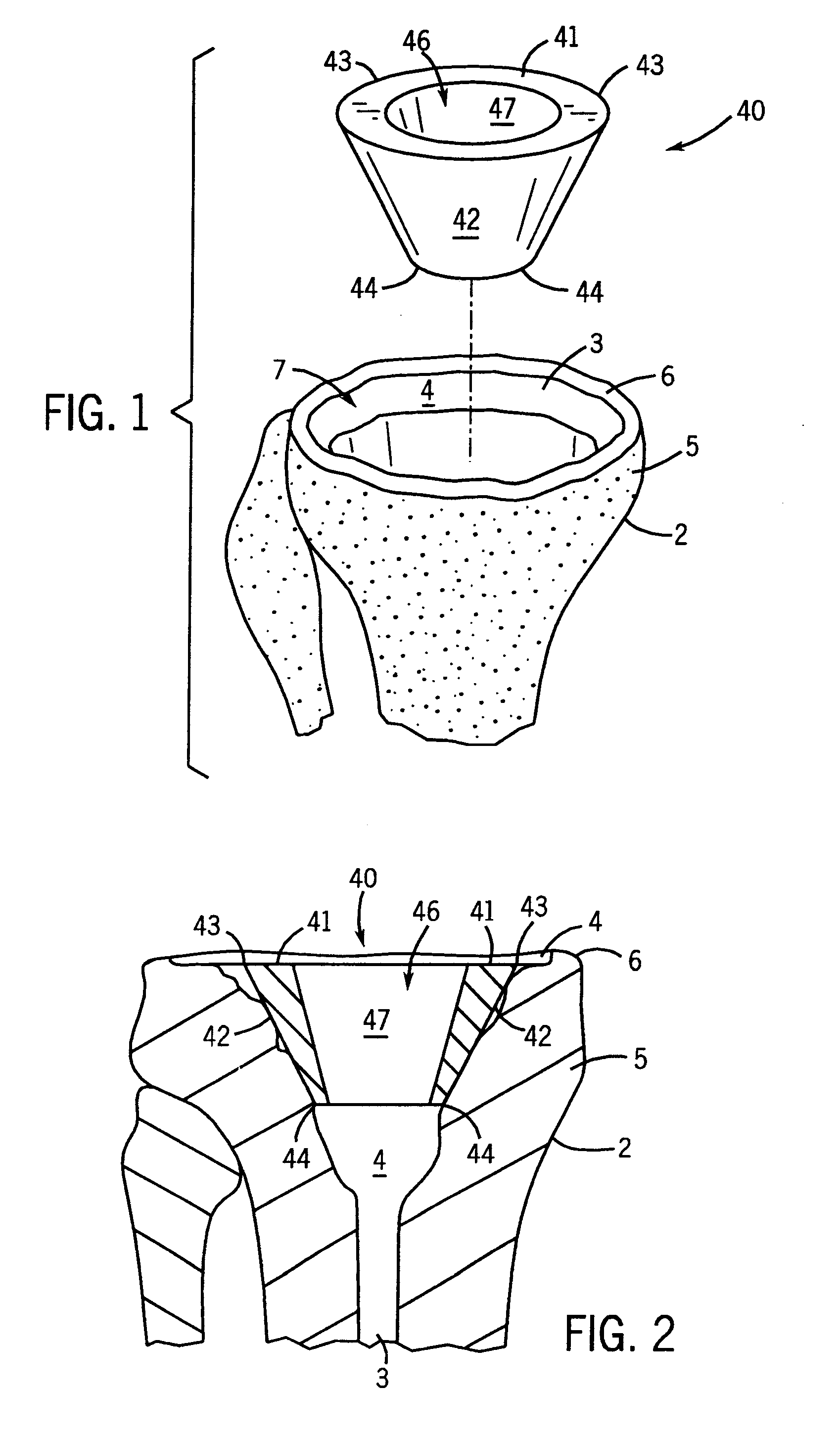

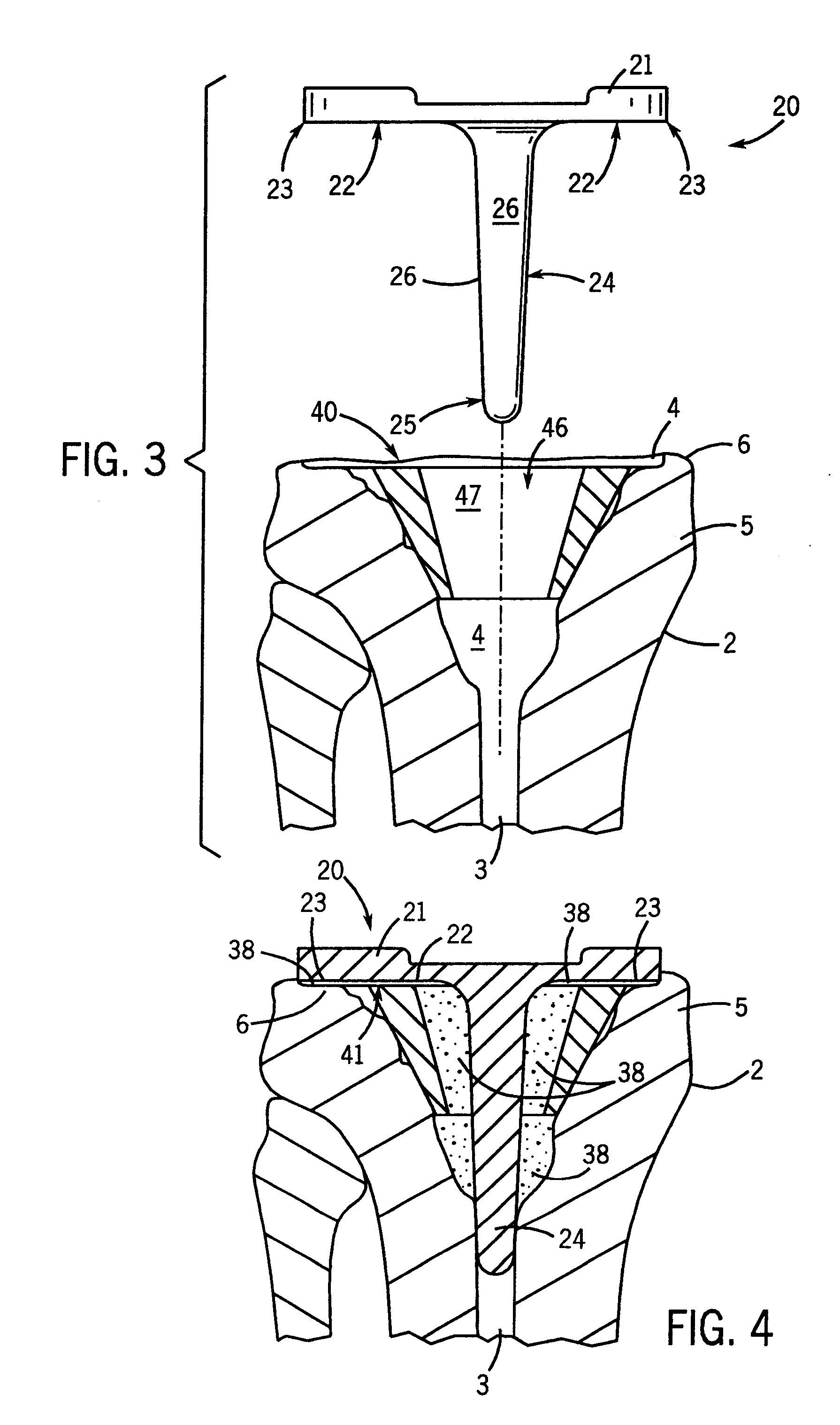

[0049]The present invention is directed to a prosthetic system that includes a prosthetic implant and a support structure secured to an inner surface of the cavity in the end of the bone. The prosthetic system and the methods for its use are illustrated and described herein with reference to the replacement of a hip joint or a knee joint. However, it should be understood that the methods and prosthetic systems according to the invention can be used in the repair of any bone or in connection with the implantation of prosthetic devices at or in any bone in the body, adjacent to or remote from any joint, including without limitation the hip, knee and spinal joints. Further, the methods and prosthetic systems according to the invention can be used in primary surgery, in which a prosthesis is being used to reconstruct a joint for the first time, as well as in revision surgery, in which a previously-implanted prosthesis is being replaced with another prosthesis. Press fit, cement or other...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com