Noise and shock reduction in rotary positive displacement blowers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

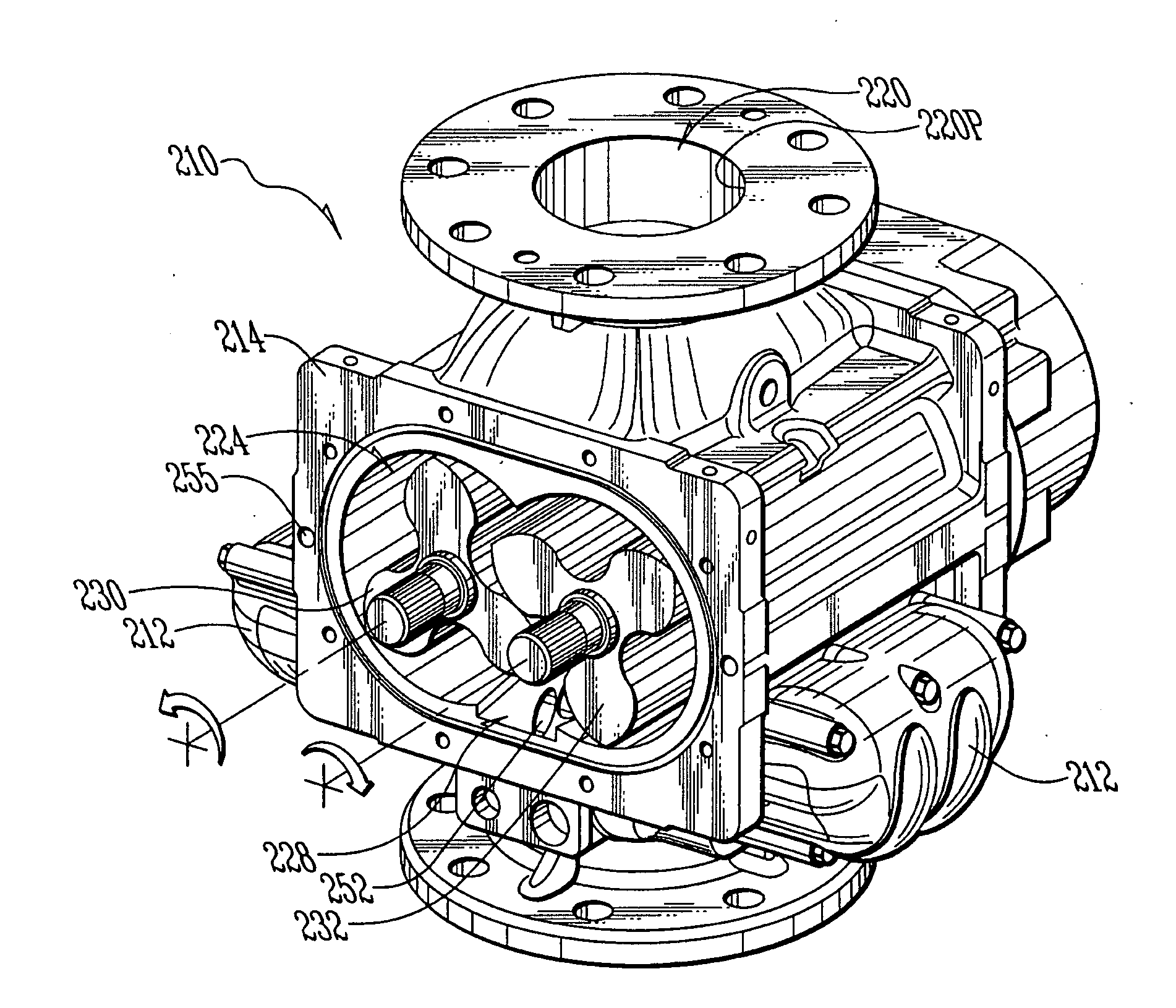

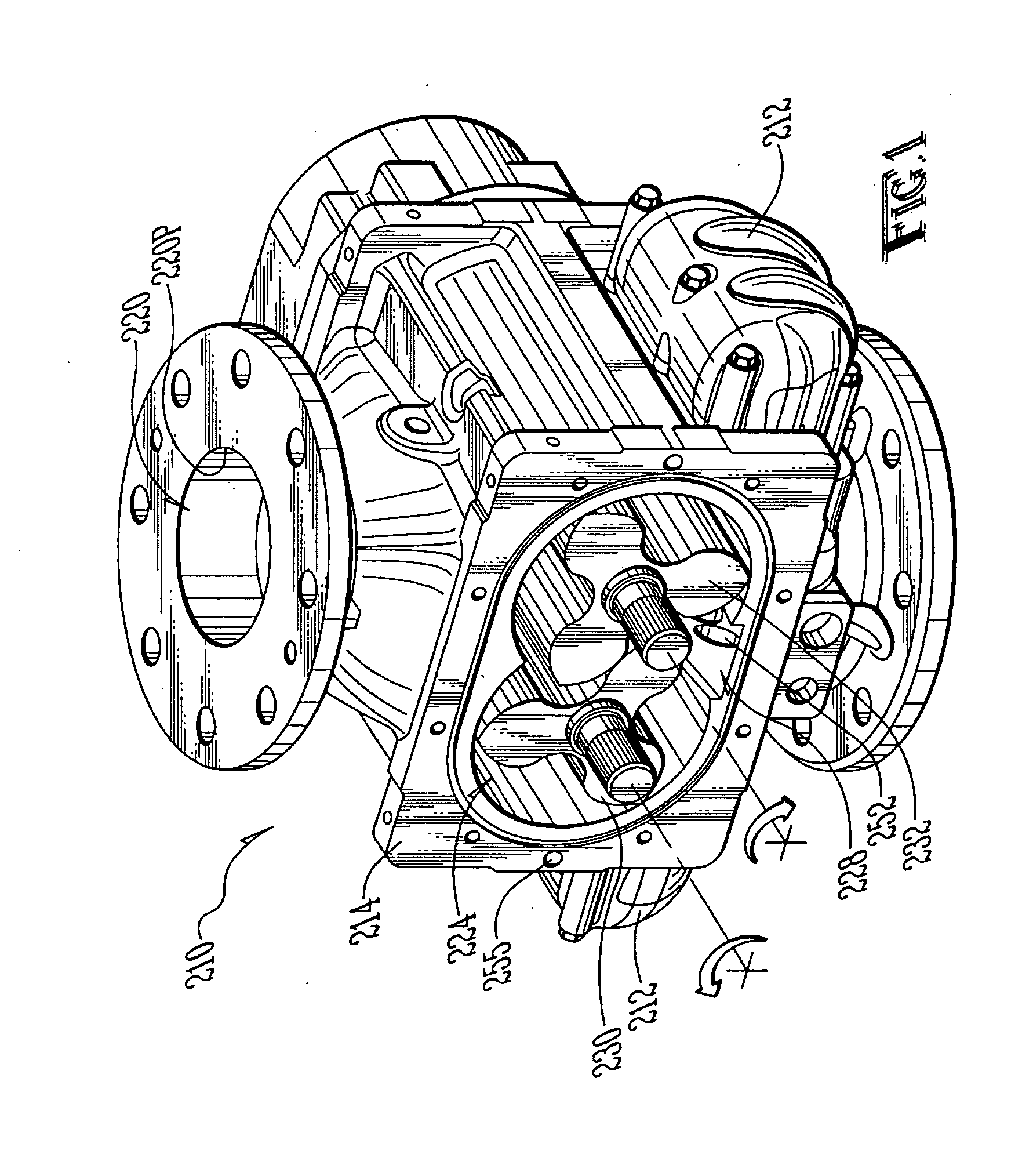

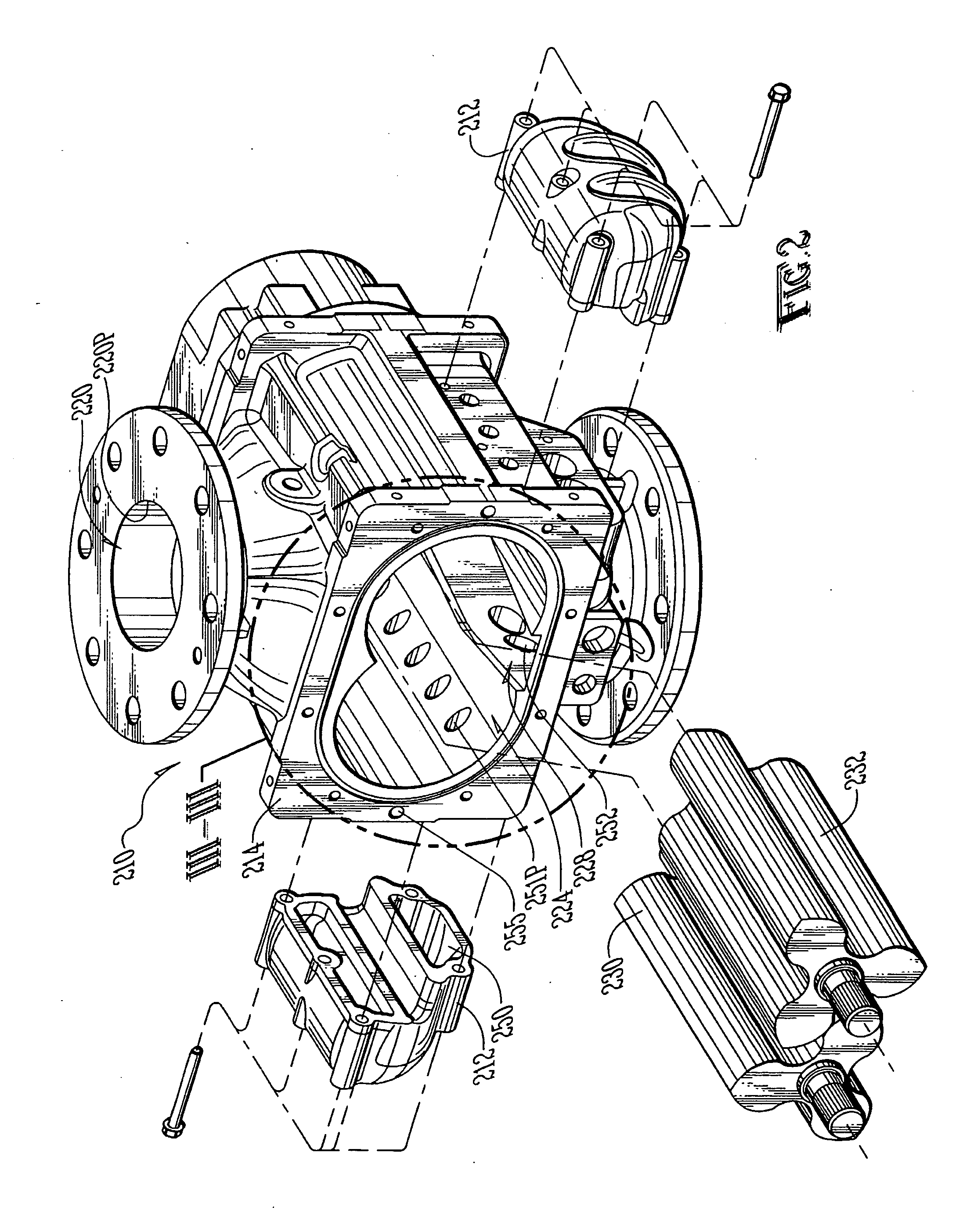

[0024]FIGS. 1 through 4 provide line drawings of a rotary positive displacement blower 210 with noise and shock reduction improvements in accordance with the invention. It is an aspect of the invention to incorporate a pair of back-pass manifolds 212.

[0025]This is a Roots style blower. FIG. 4 shows better that, it has a substantially hollow housing 214 defining an inlet plenum 220, a rotor chamber 224, and a discharge plenum 228. (Preferably the housing 214 is cast, but the flange surfaces would be machined and ground.)

[0026]A pair of rotors 230 are disposed in the rotor chamber 224. The rotors 230 would be sealed inside by a pair of opposed end plates (far side end plates shown in FIGS. 1 and 2). The rotors 230 are driven to rotate counter-rotationally to each other. For instance, the left rotor 230 rotates counter-clockwise (CCW).

[0027]In the drawings, the blower 210 is shown with the inlet port 220P up and the discharge port 228P down. However, the blower 210 can be mounted in an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com