Hammock stand with welded structural supports

a technology of structural supports and hammocks, which is applied in the direction of socks, manufacturing tools, transportation and packaging, etc., can solve the problems of not producing a weld joint, one weld joint is most prone to weakening, and catastrophic collapse, and achieves stronger, more durable weld joints.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014]Further scope and applicability of the present invention will become apparent from the detailed description given herein. However, it should be understood that the detailed description and specific examples, while indicating embodiments of the invention, are given by way of illustration only, since various changes and modifications within the spirit and scope of the invention will become apparent to those skilled in the art.

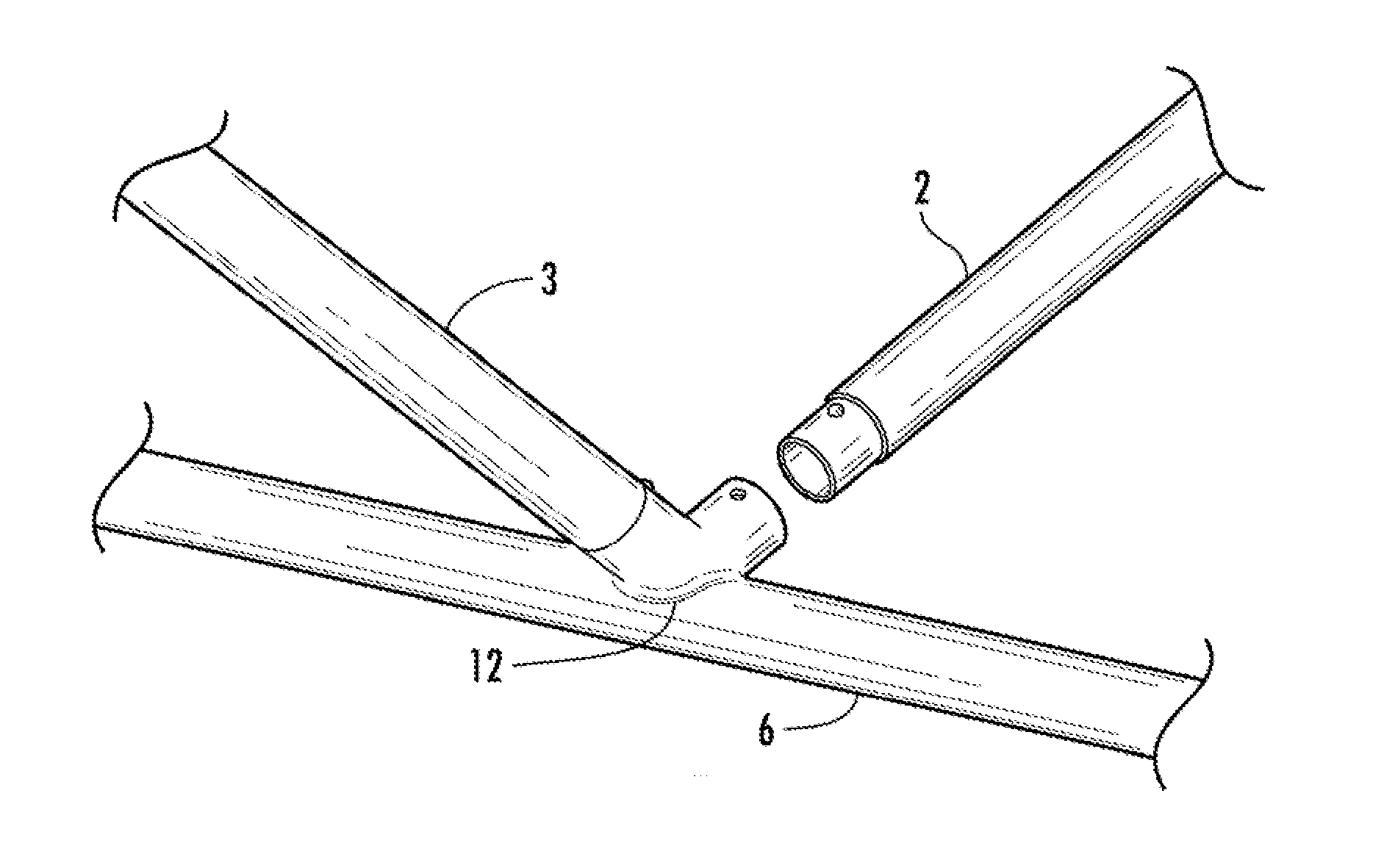

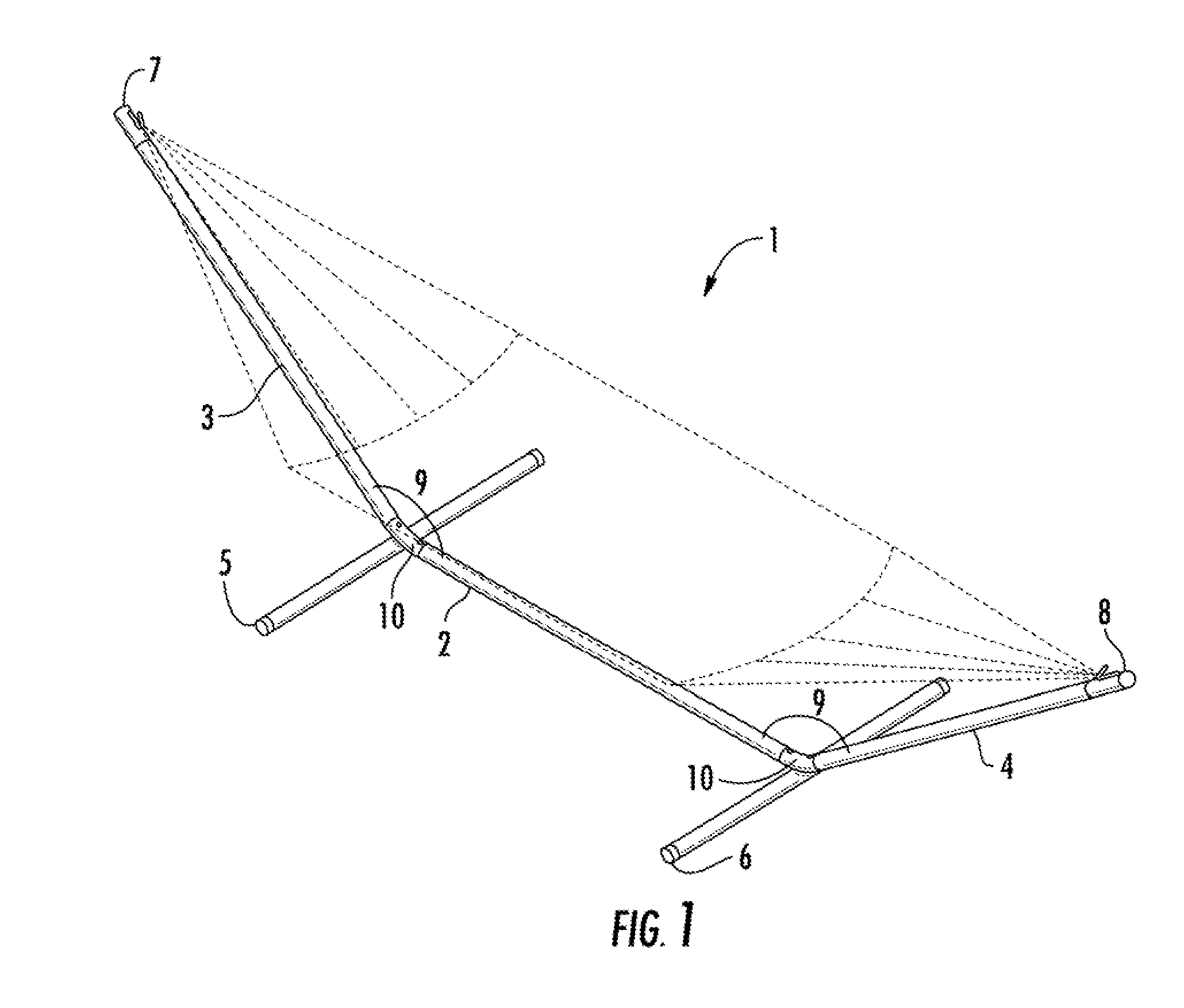

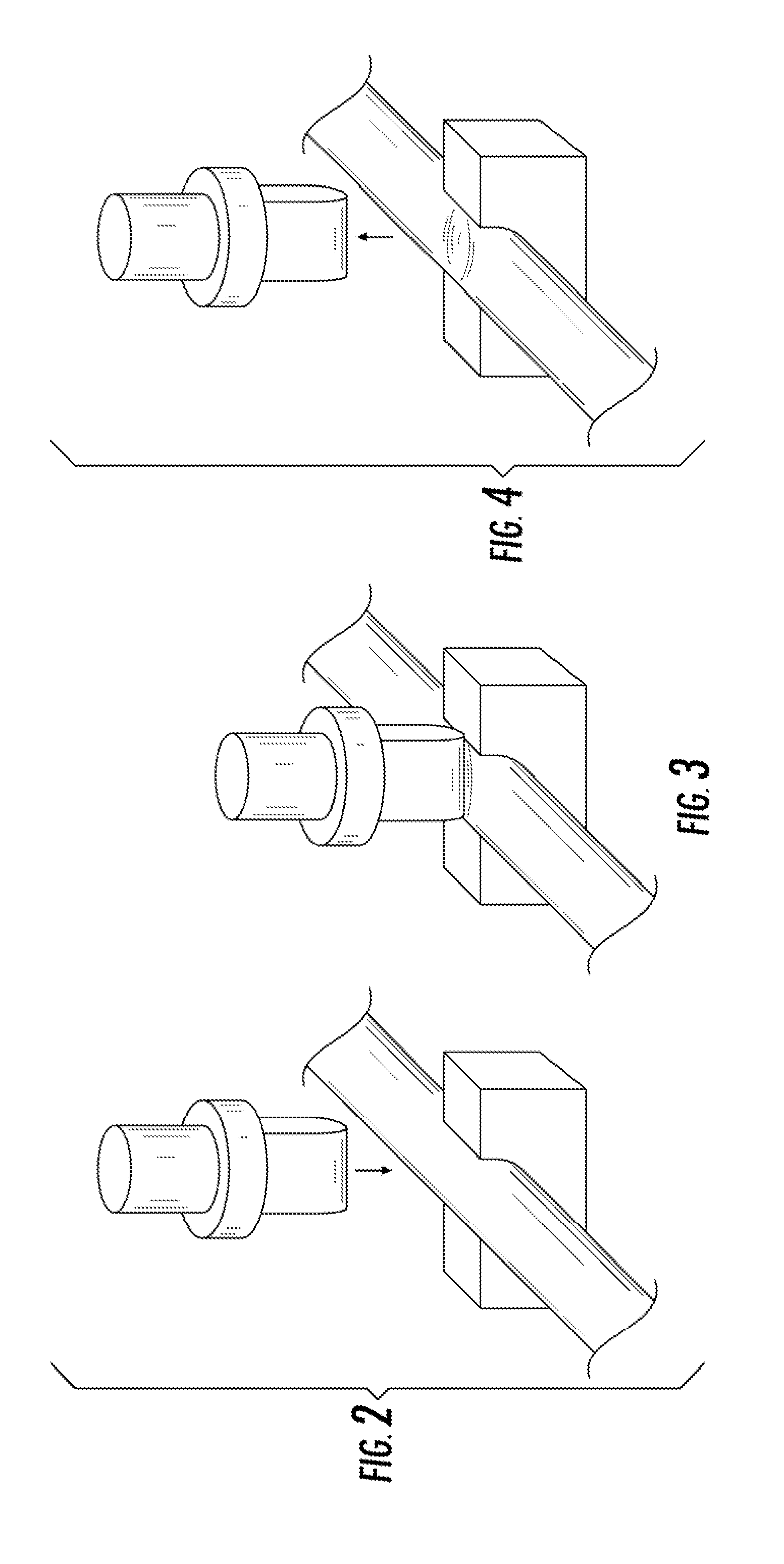

[0015]In accordance with the present invention a stand is provided for supporting a hammock in suspended configuration above the ground. The device of the invention comprises an elongated base member comprising a central member, upwardly extending cantilever members, and one or more support members mounted transverse to the base member to maintain the base member in an upright orientation. The central member is engaged to the cantilever members to form a unitary structure. The engagement of the these respective sections which form the composite structure ma...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com