Plaited glove

a technology of gloves and etching, applied in the field of cut-resistant gloves, can solve the problems of etching weakening the yarn, reducing the strength of the filament, and typically weakening the yarn in the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

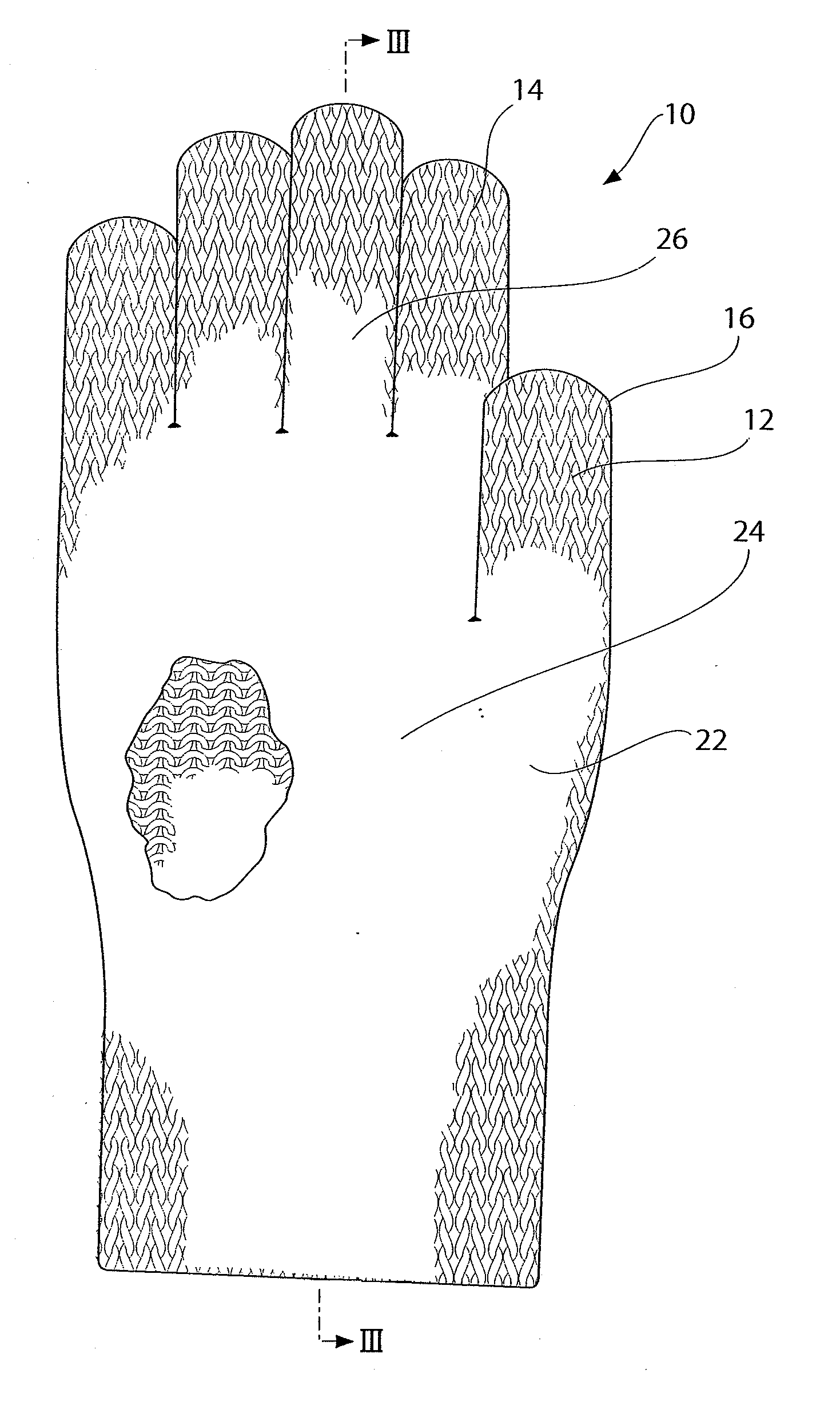

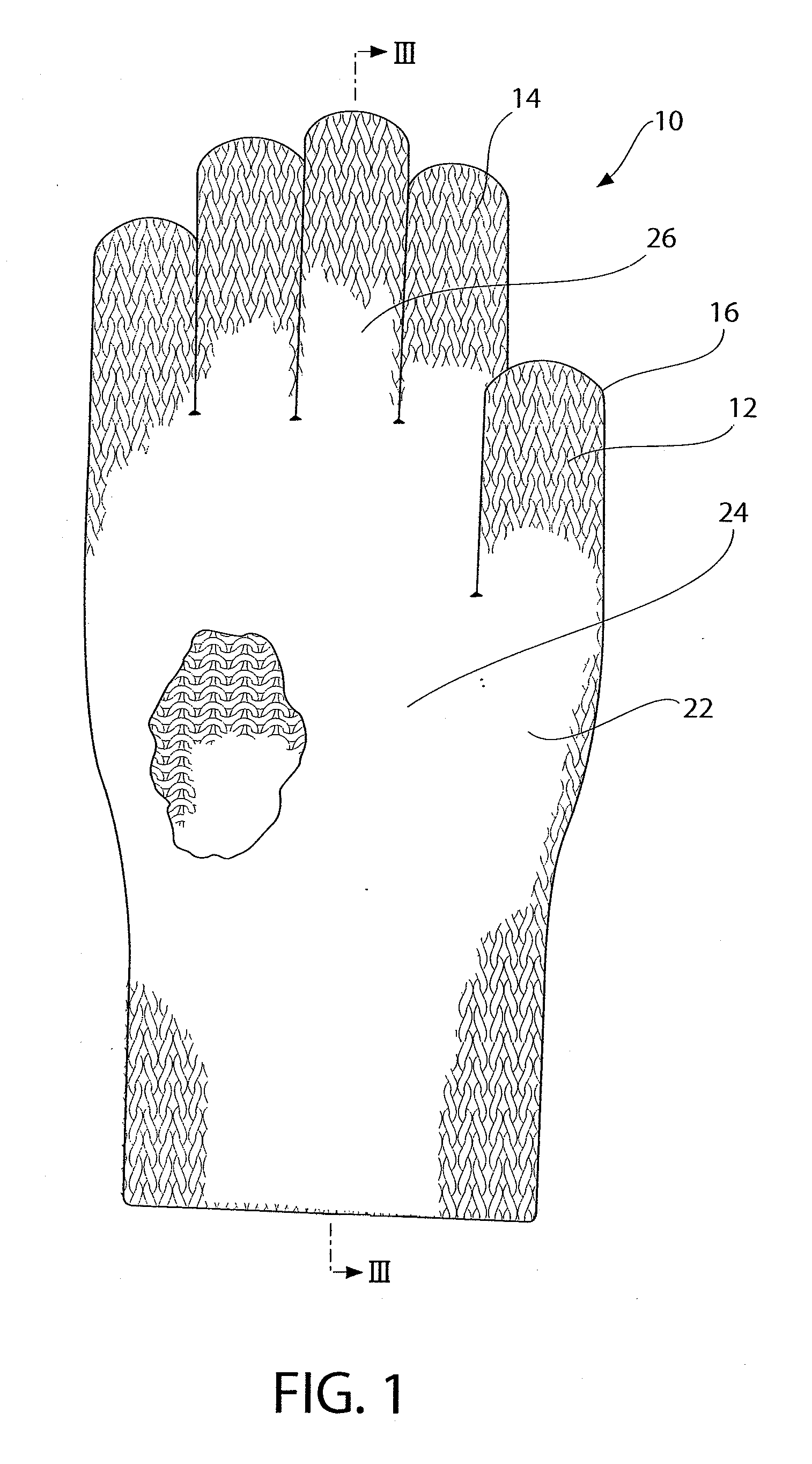

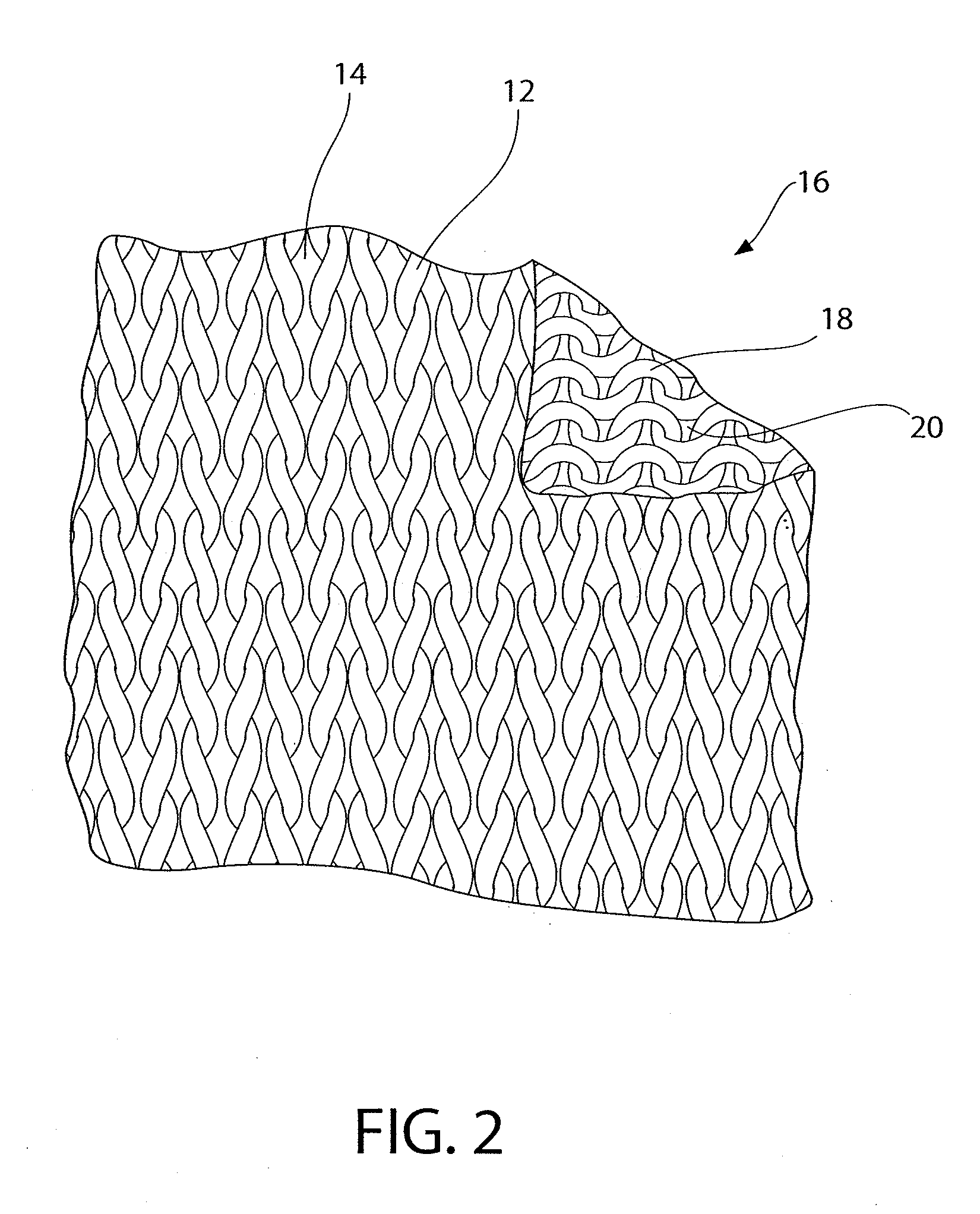

[0027]The present invention is directed to plaited gloves knit with non-stretchable filament yarn on the outside. The present invention utilizes the rolling action of the parallel filaments as its key component for cut resistance and wear. Wear becomes a necessary part of hand protection because as a glove surface wears down, its cut resistance is severely diminished. By placing the non-elastic yarn on the outside of the glove, the most abrasion resistant component (the filament) is on the outside. Additionally, when the filament fibers of the cut resistant yarn are parallel to each other, they can roll on each other for increased cut resistance. An added benefit is that the parallel filaments are less likely to trap dirt and can be cleaned more easily in a laundering process. Non-elastic filament also increases the puncture resistance.

[0028]The safety glove industry has always been concerned with wear factor of cut resistant gloves as safety personnel know that as a glove surface w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com