Automated loader with cone horn

a loader and cone horn technology, applied in the direction of transportation and packaging, packaging foodstuffs, packaged goods types, etc., can solve the problems of consumers not being able to appreciate and the production is considerably slow, so as to prevent or minimize contact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

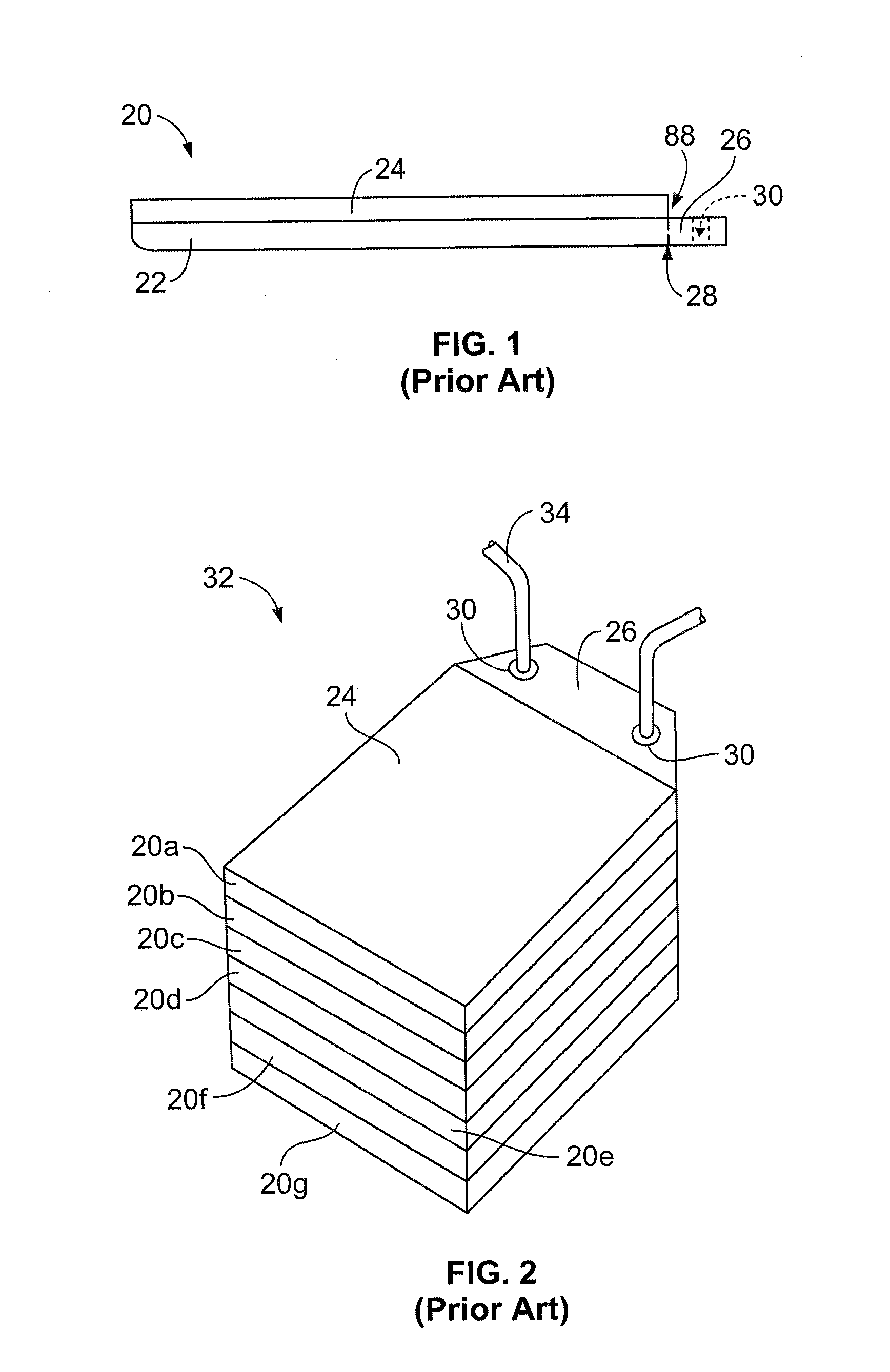

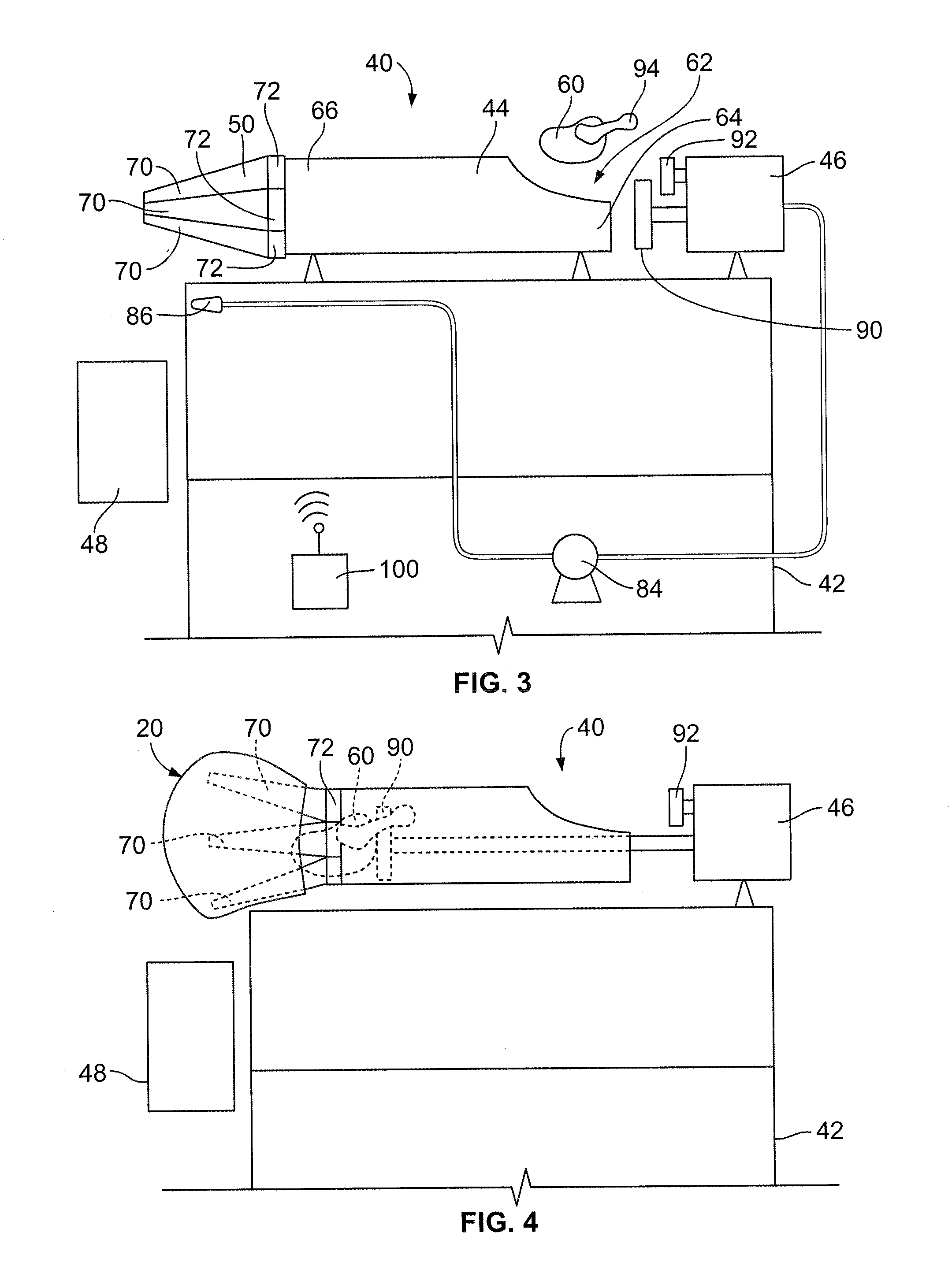

[0021]While the invention may be susceptible to embodiment in different forms, there is shown in the drawings, and herein will be described in detail, specific embodiments with the understanding that the present disclosure is to be considered an exemplification of the principles of the invention, and is not intended to limit the invention to that as illustrated and described herein. The embodiments of the present invention will be described as part of a bag opener to be incorporated in an automated poultry loader. The present invention, however, can also be used on loaders for bagging and / or netting whole poultry, cut-up poultry, or whole muscle meat products, on other applications in which a material is enclosed in a casing, bag, or netting, such as sealants, adhesives, and explosives, or for any other application in which a bag must be opened in order to insert material to be bagged.

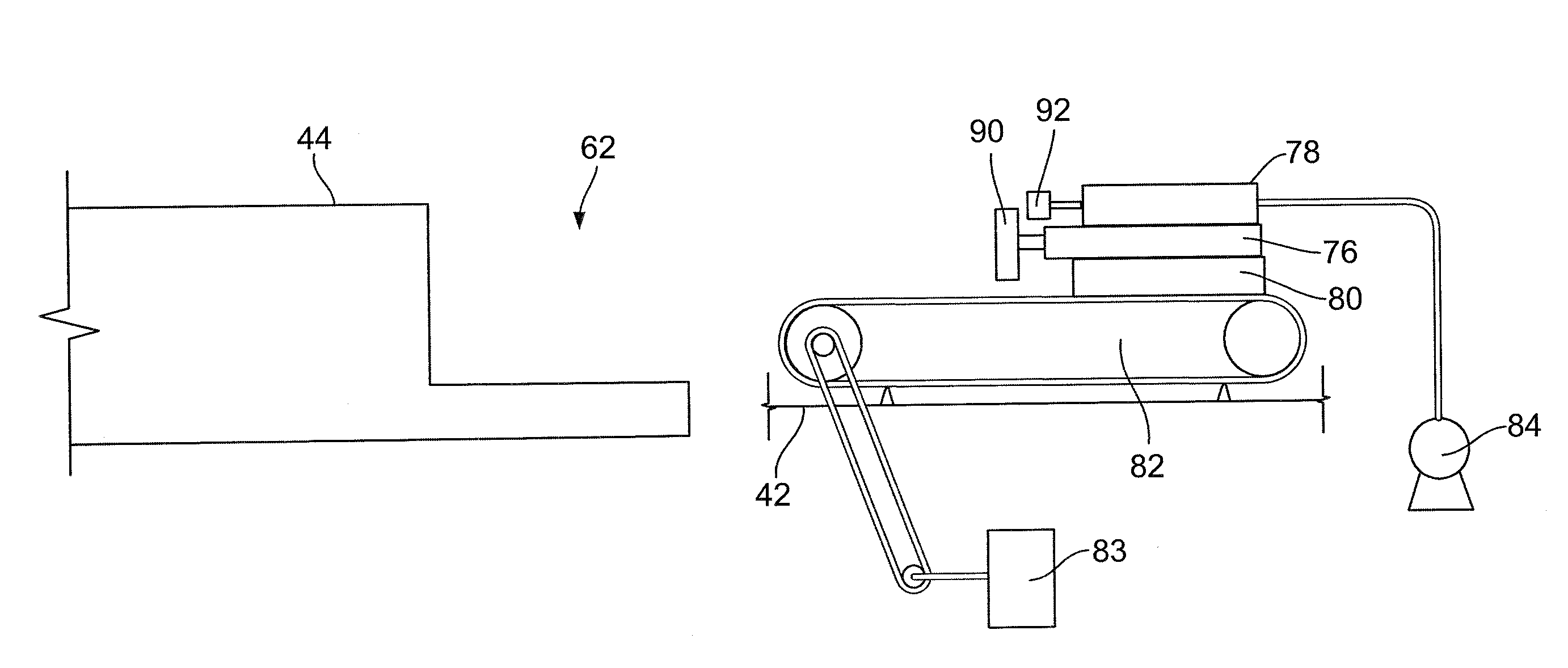

[0022]The preferred embodiment of the automated loader of the present invention is shown in elevati...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thermoplastic | aaaaa | aaaaa |

| coefficient of friction | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com