Screw cap with a cutting sleeve

a screw cap and cutting sleeve technology, applied in the field of screw caps, can solve the problems of difficult to achieve metered dispensing, high and controlled, and achieve the effect of reducing the chance of liquid spilling ou

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

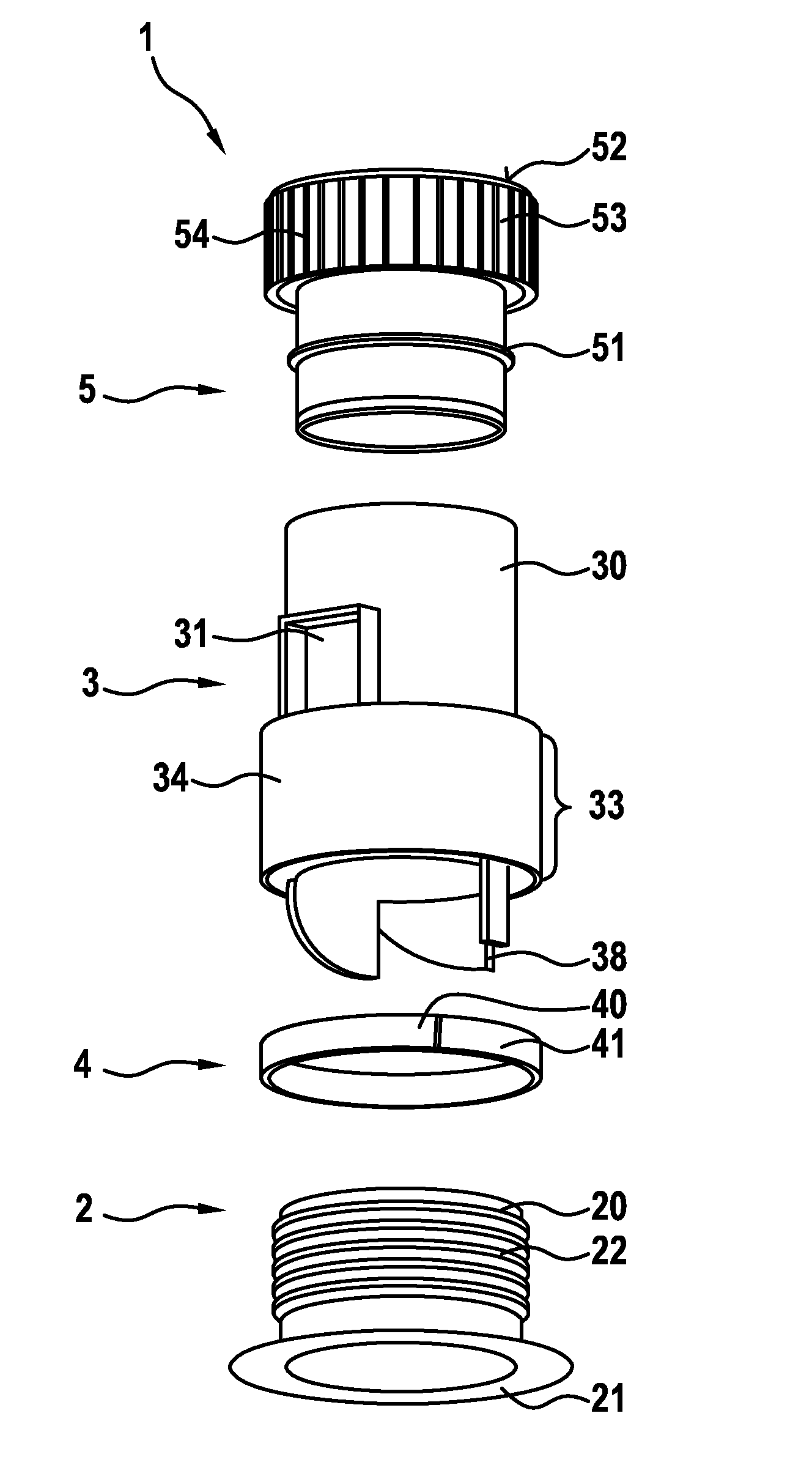

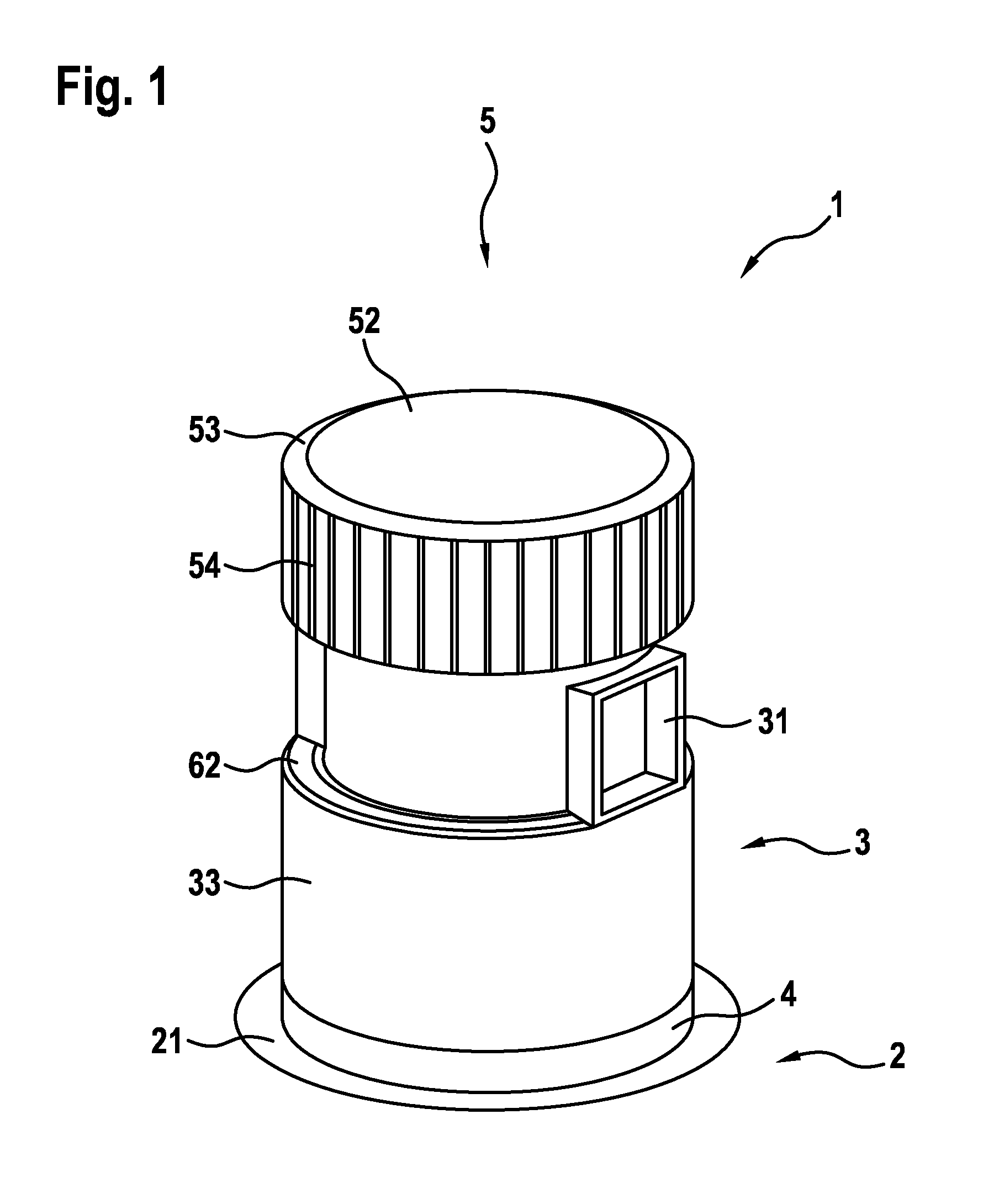

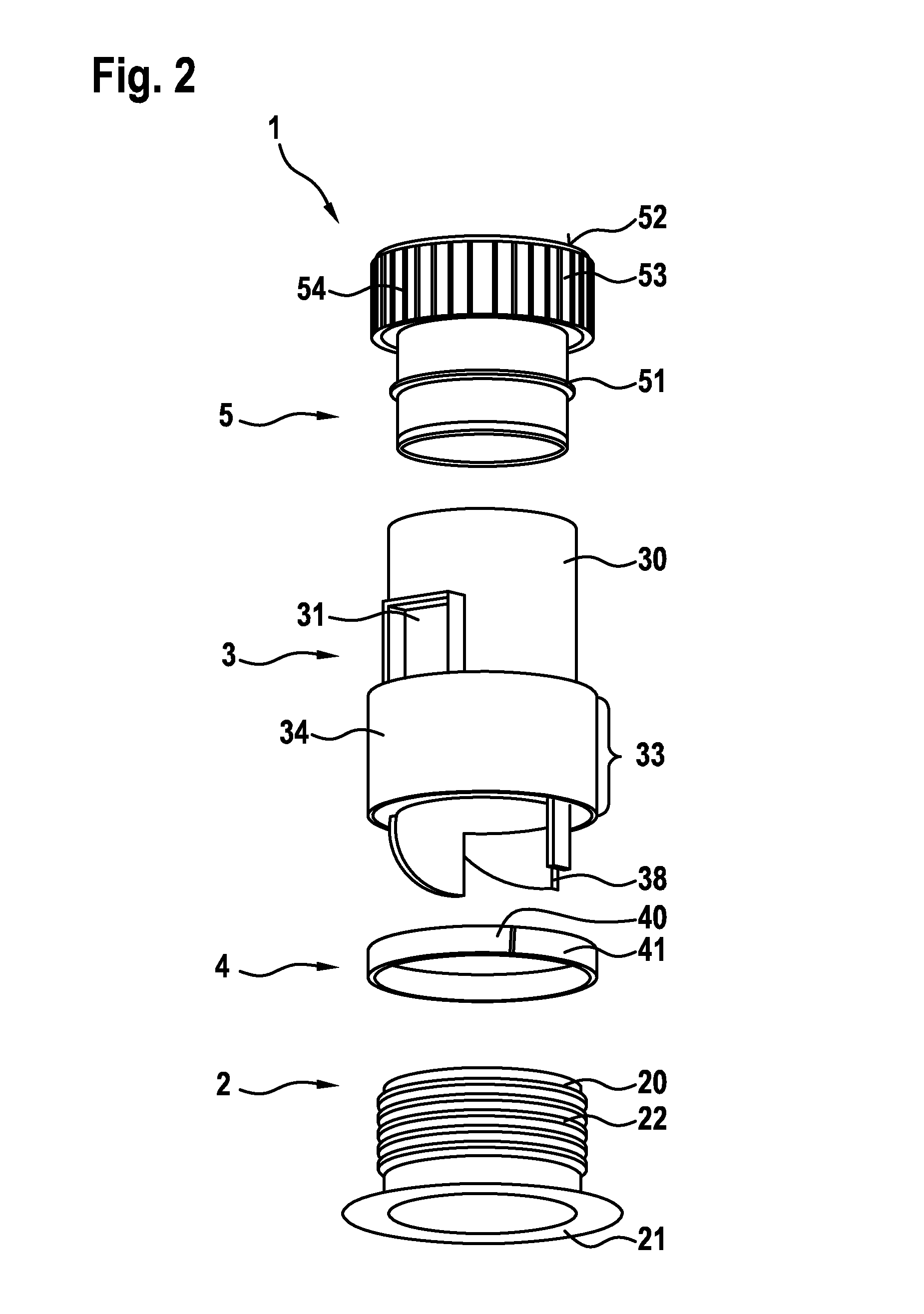

[0015]The self-opening screw cap is denoted in its entirety with the reference numeral 1. The same screw cap could however be just as well referred to as a metering closure because the invention relates to a combination of a self-opening screw cap and a metering closure. The inventive screw cap consists of four components, namely a lower part 2, a cutting sleeve 3, a spacing means 4 and a valve piston 5 which is designed as a rotary handle in the uppermost region, wherein only this part is visible in the assembled state. The screw cap of interest here is, as previously mentioned, mounted on a closed container made of film. To this end, the lower part 2 comprises an outwardly protruding, circumferential flange 21. The cutting sleeve 3 has a lateral metering opening 31, which in this case is implemented relatively large as a square window. Prior to initial use, the spacing means 4 is still present, which can be embodied either as a spacing ring or as a tamperproof strip 40. On the one...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| axial displacement | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com