Minimal glove capable of direct and removable adherence to a palm

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

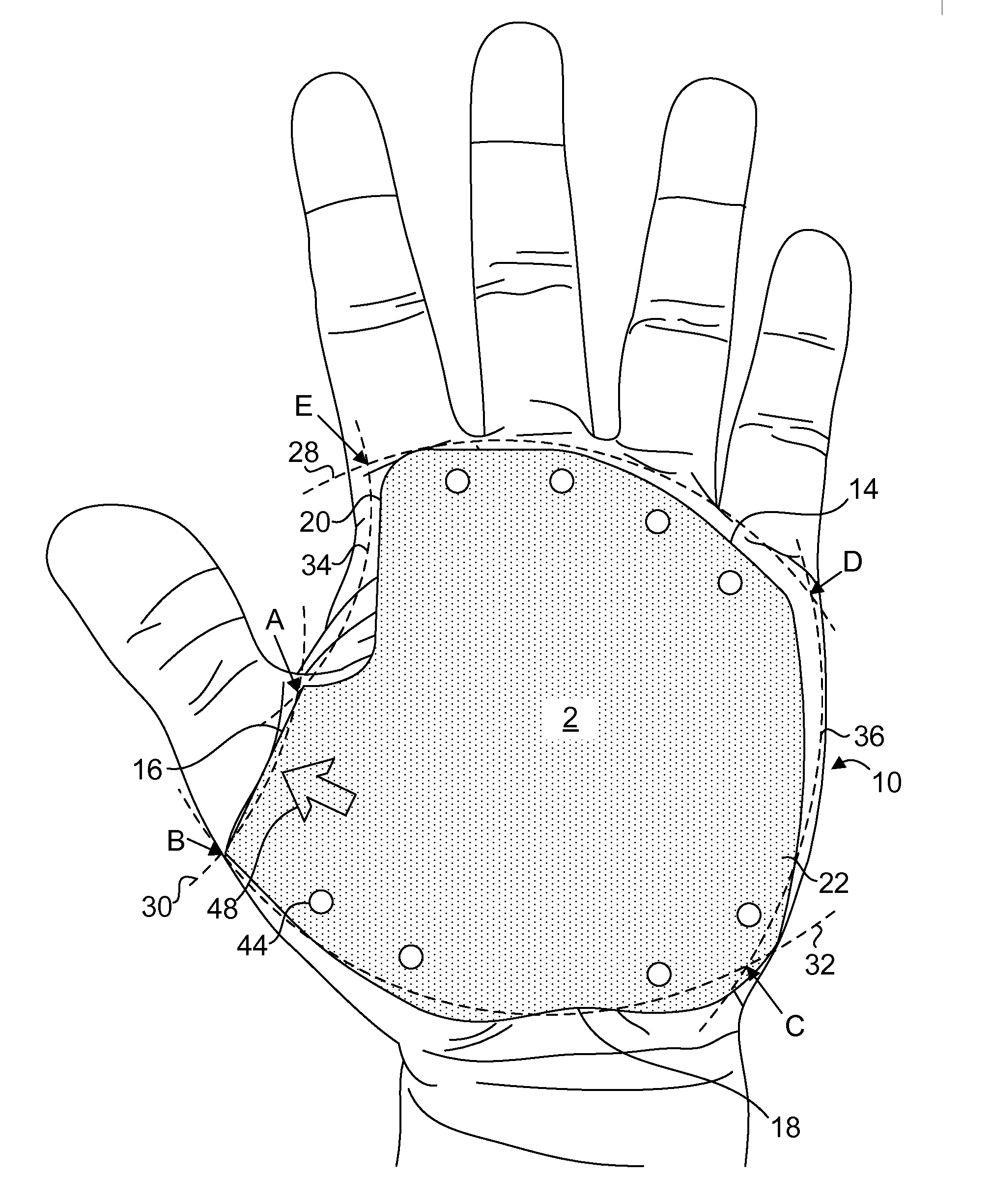

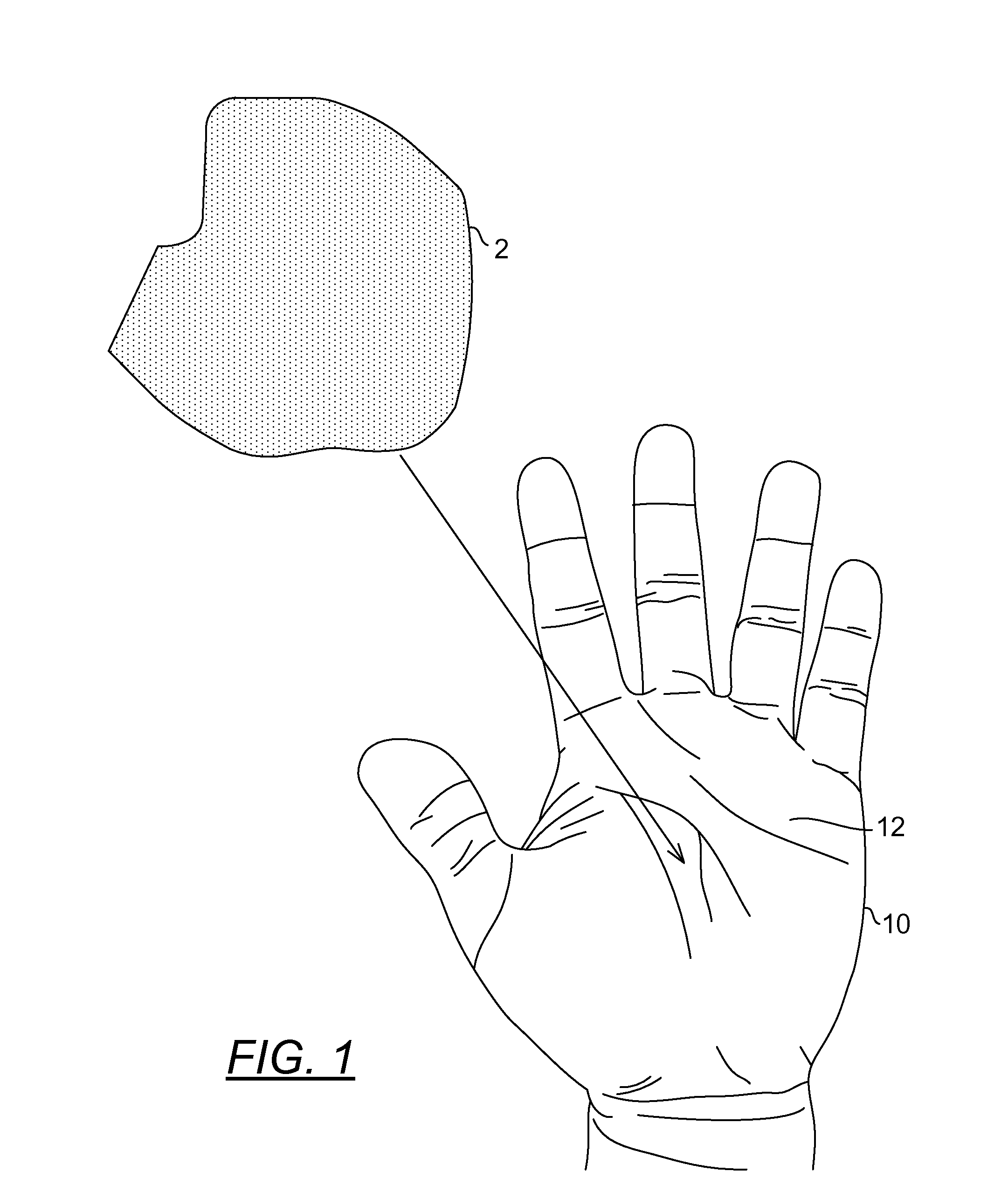

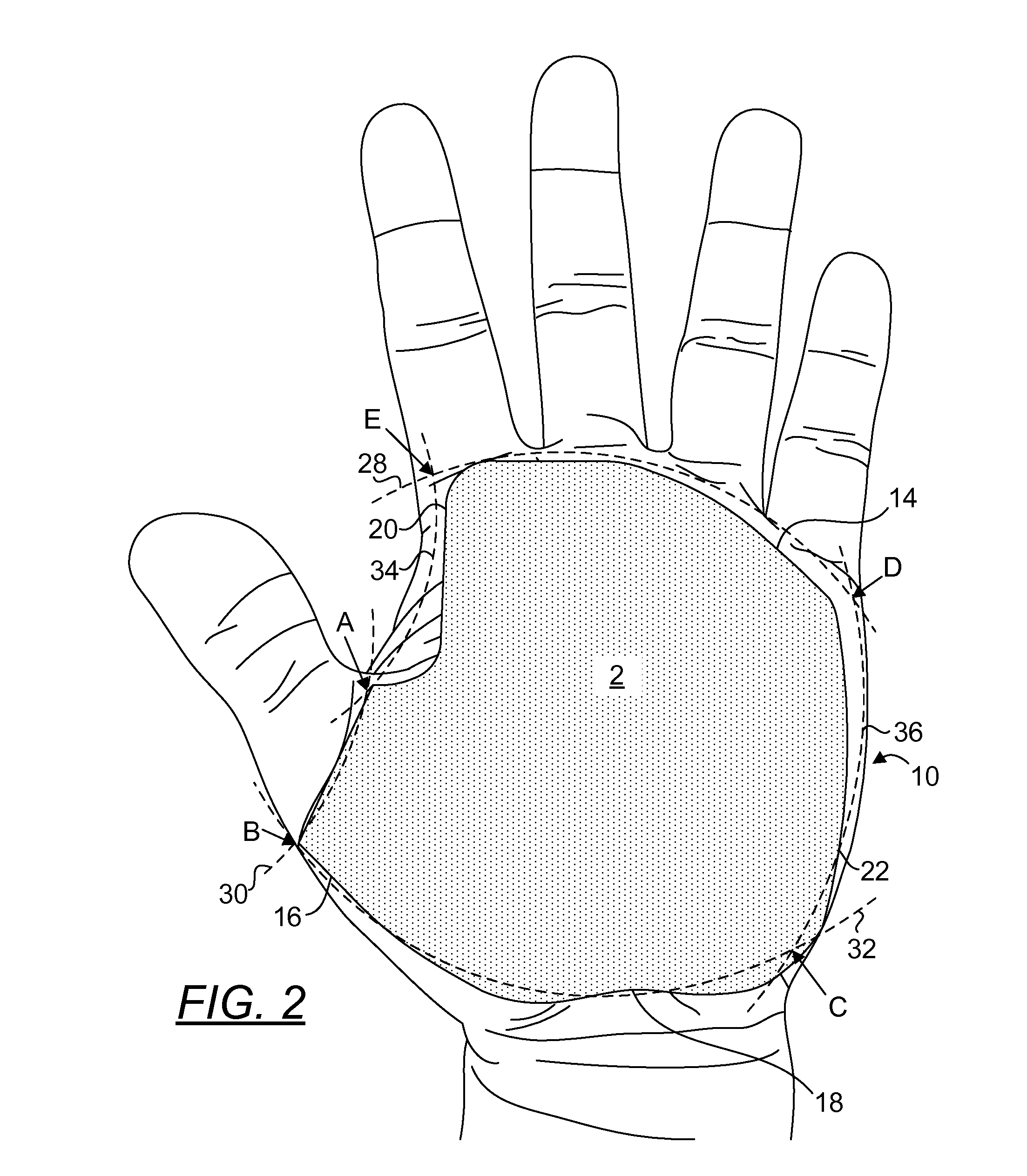

[0055]The term “about” is used herein to mean approximately, roughly, around, or in the region of. When the term “about” is used in conjunction with a numerical range, it modifies that range by extending the boundaries above and below the numerical values set forth. In general, the term “about” is used herein to modify a numerical value above and below the stated value by a variance of 20 percent up or down (higher or lower). FIG. 1 is a top orthogonal view of a present palm glove 2 arranged to be secured to the palm 12 of a left hand 10. FIG. 2 is a top orthogonal view of a present palm glove 2 having been secured to the palm 12 of a left hand 10. A similarly configured glove can be used for a right hand. The glove 2 is configured to cover substantially the entire surface of the palm 12 without affecting the dexterity of the hand 10. The thumb edge 16 of the glove 2 terminates at about the thumb area 30 of the hand 10. The dorsal edge 20 of the glove 2 terminates at about the dorsa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com