Floor scrubbing machine

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Example

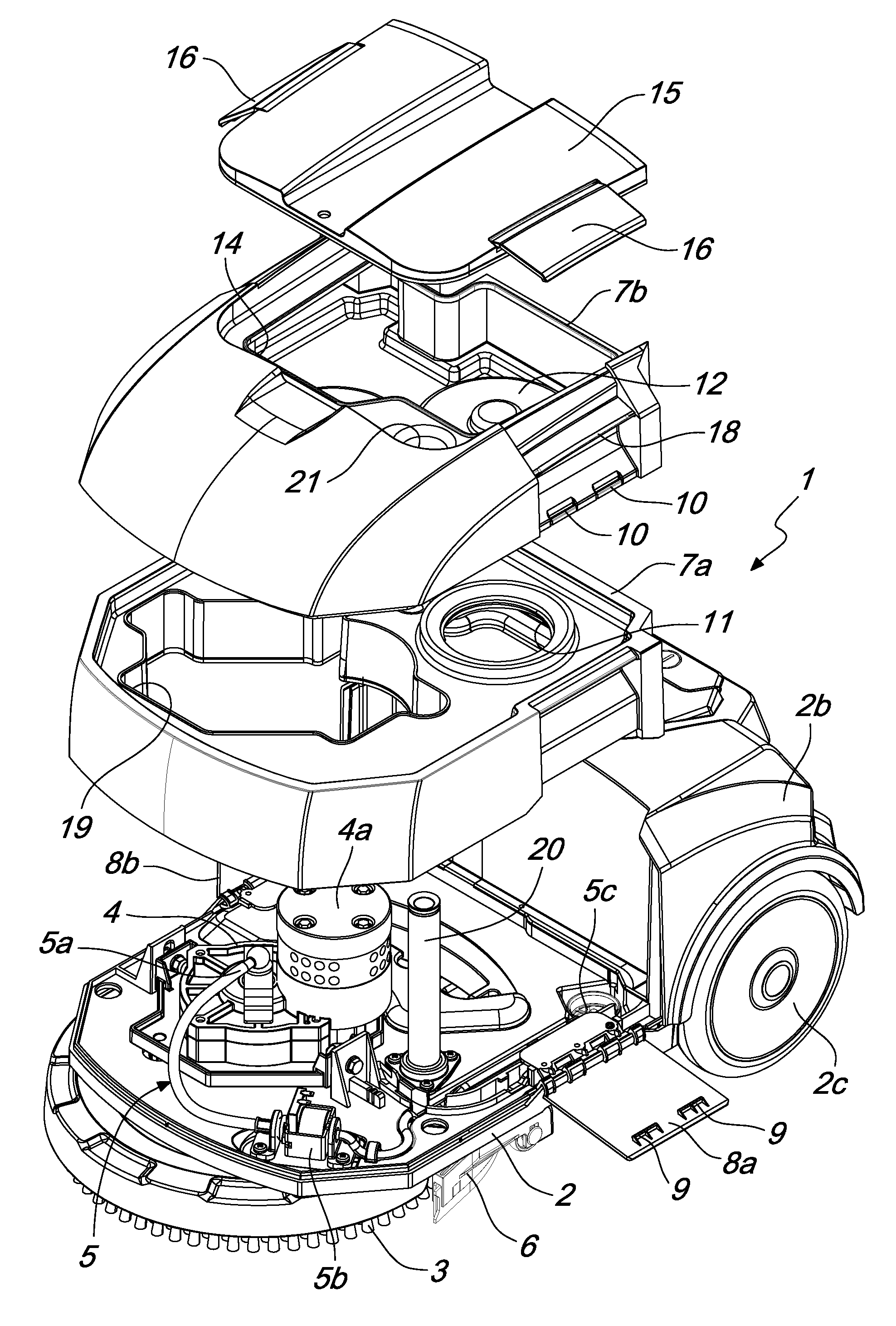

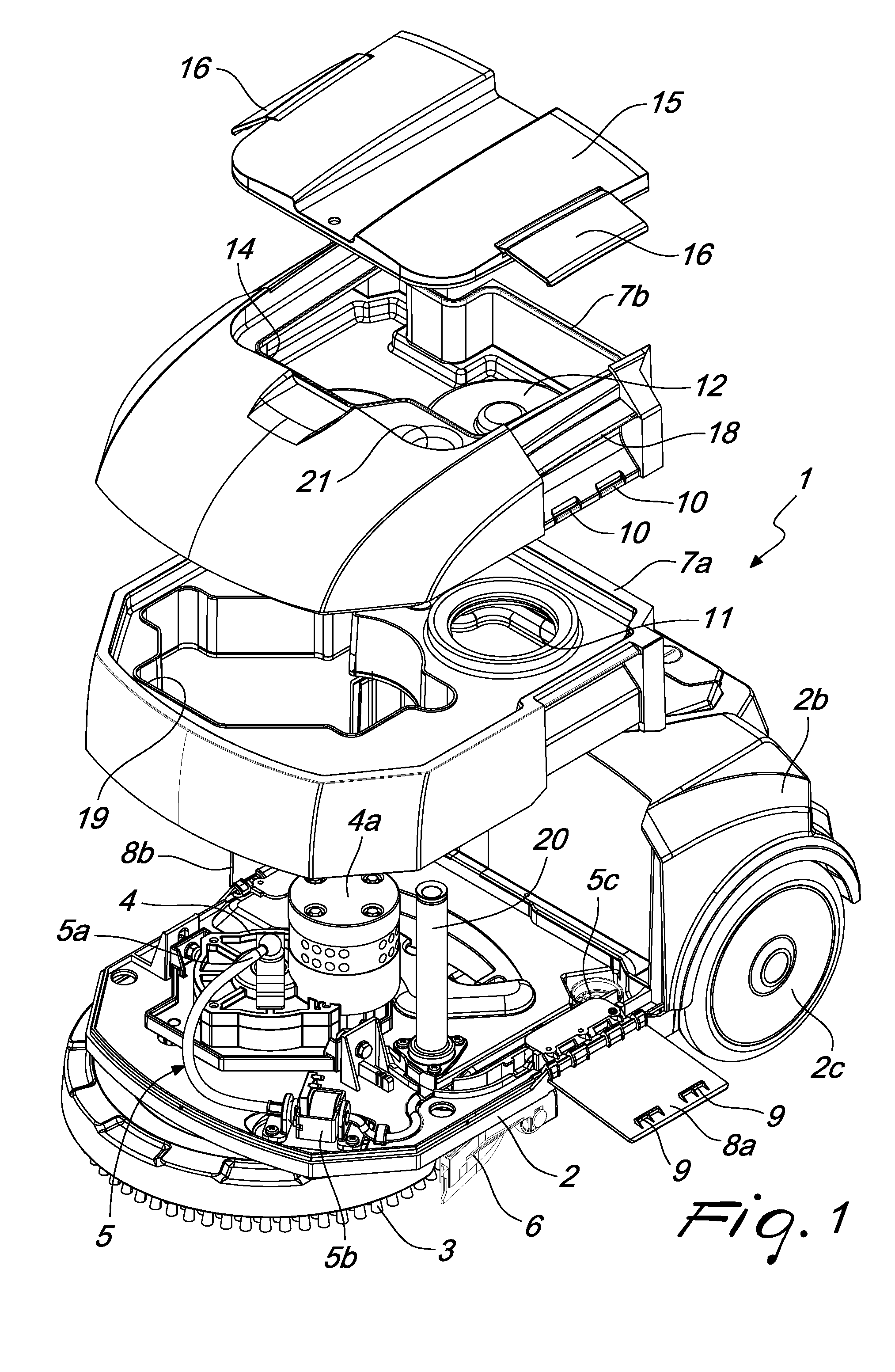

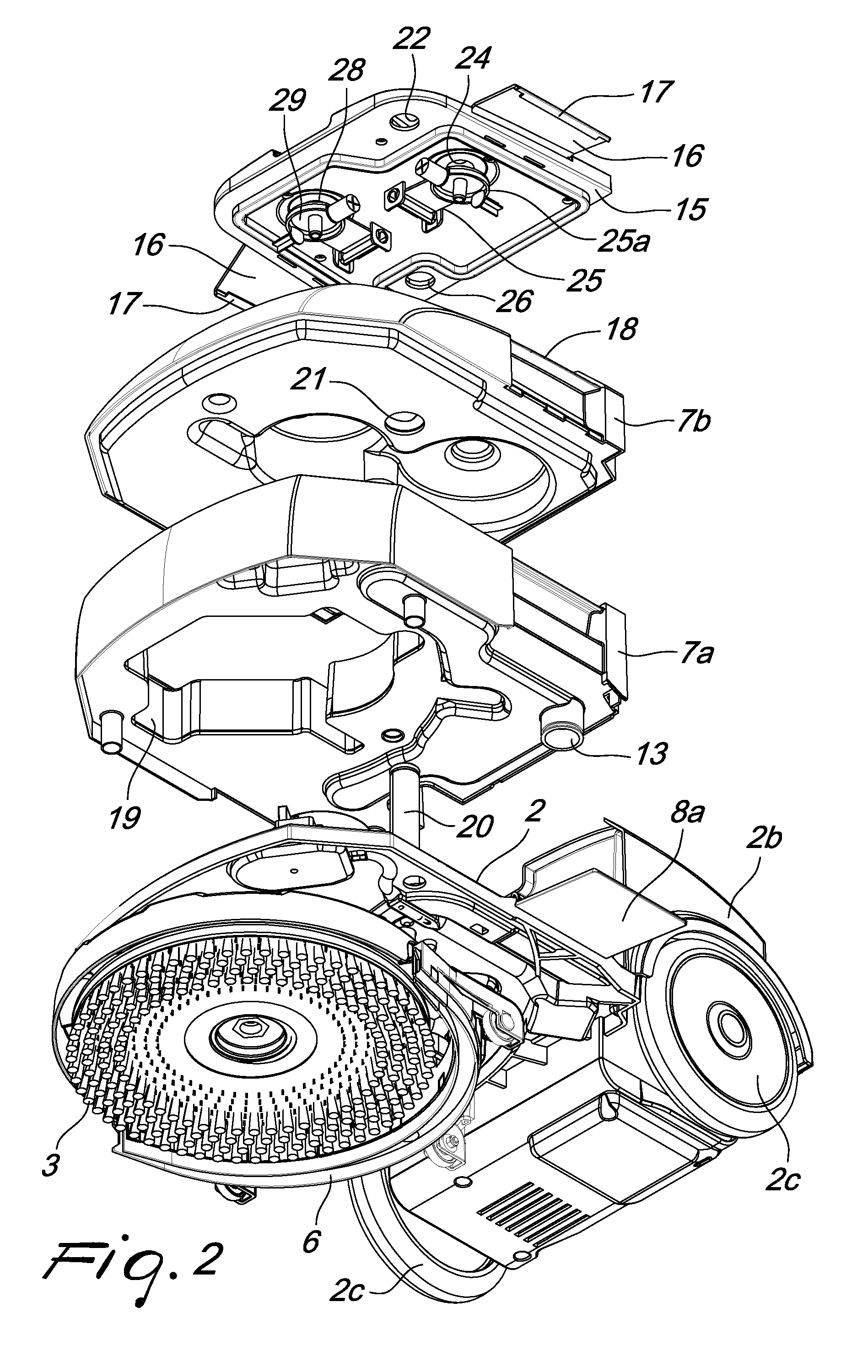

DETAILED DESCRIPTION OF THE DRAWINGS

[0018]With reference to the figures, a floor scrubbing machine according to the disclosure, generally designated by the reference numeral 1, comprises a footing 2, which supports at least one brush 3, which can be activated rotationally by an actuation assembly 4, which is also mounted on the footing 2 and comprises an electric motor 4a, and at least one device 5 for dispensing a washing liquid, which is constituted for example by a nozzle 5a and by a pumping device 5b, also mounted on the footing 2 and conveniently connected with its intake to a filter 5c that is also mounted on the footing 2.

[0019]To the rear of the brush 3, the footing 2 further supports a squeegee 6 and at least one suction device, which comprises a suction intake, associated with the squeegee 6, which allows to pick up from the floor the washing liquid and the dirt removed by the brush 3, in order to leave the floor dry and clean when the machine passes.

[0020]An enclosure 2b ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com