Wipe dispenser

a dispenser and wipe technology, applied in the direction of flat article dispensing, thin material handling, packaging, etc., can solve the problem that the amount of fluid cannot be easily decreased, and achieve the effect of convenient vertical use, convenient wipe separation, and smooth and easy manufacturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

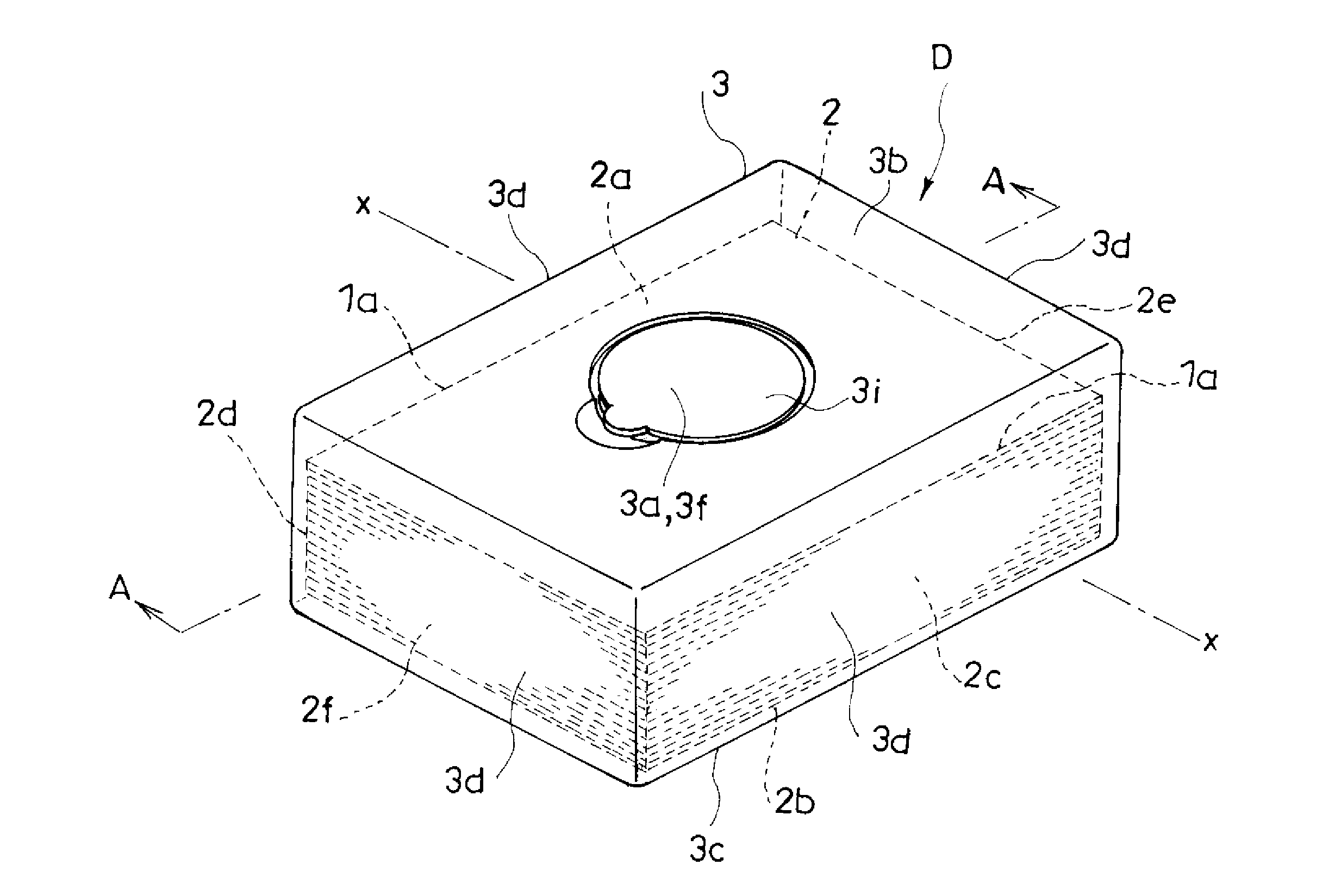

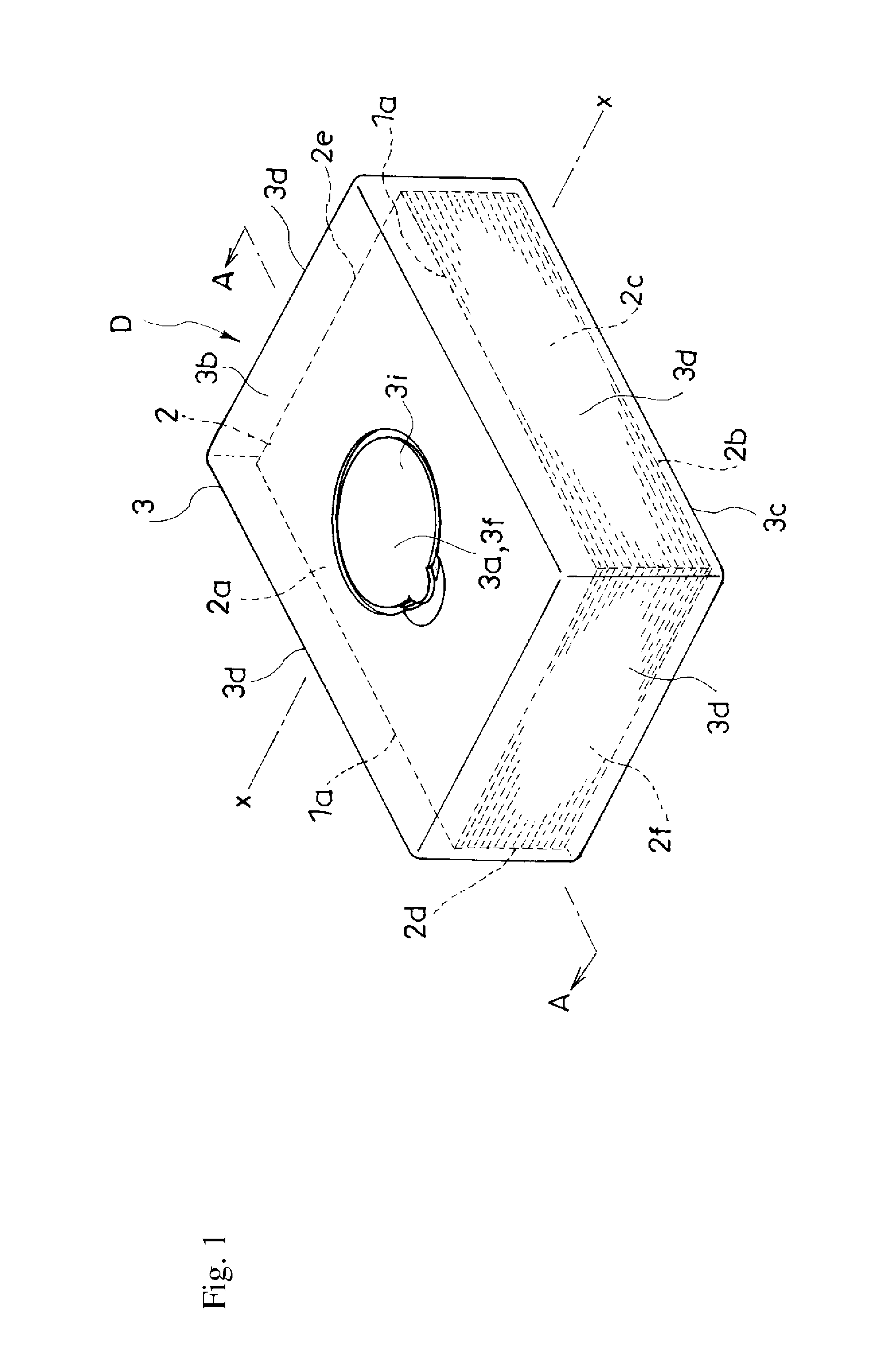

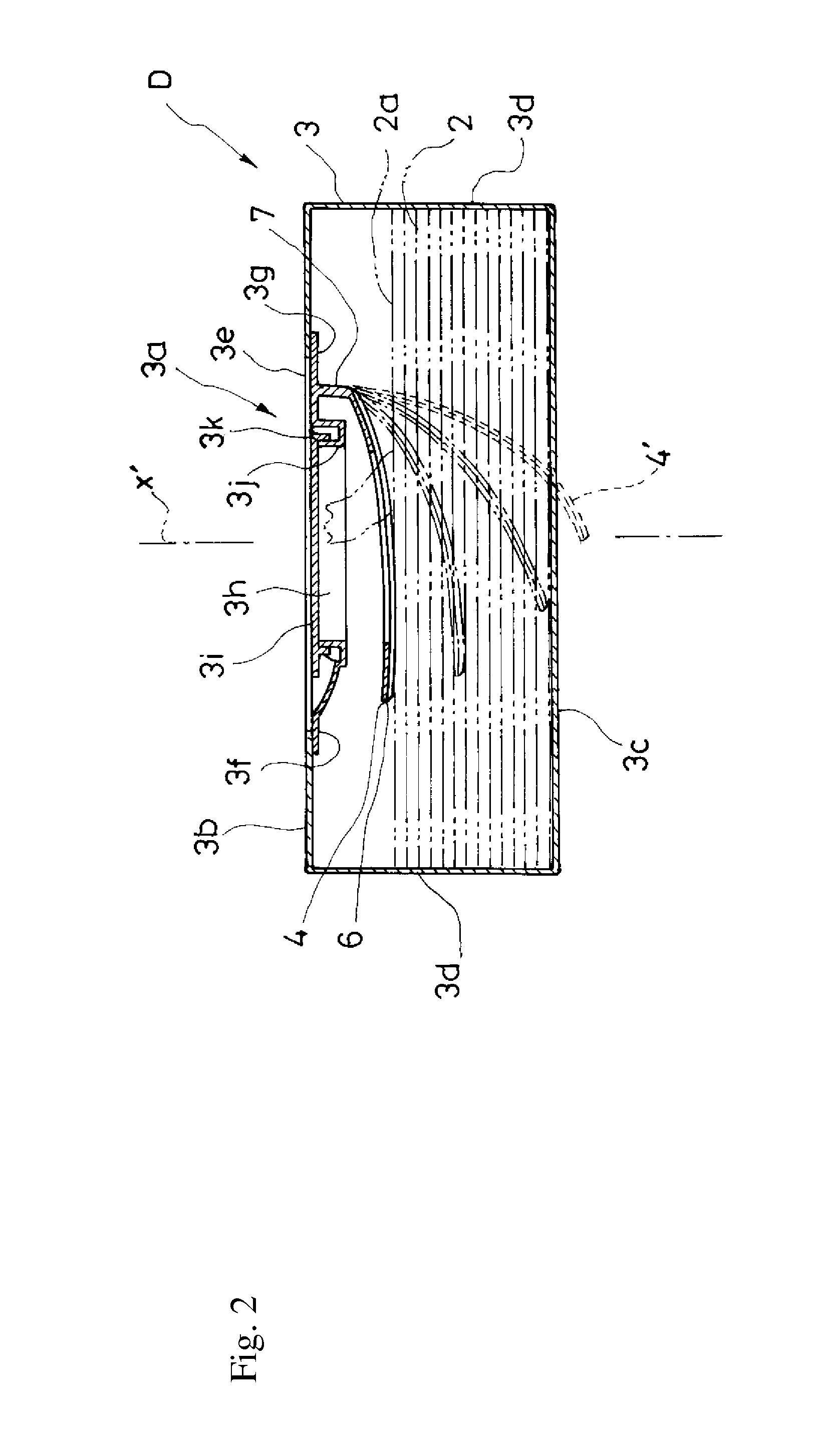

[0046]A typical embodiment of the present invention is now described hereinafter with reference to FIGS. 1 to 25. A wipe dispenser D according to this embodiment has a stacked body 2 configured by sheet-like wipes 1, a storage body 3 that stores the stacked body 2 and has, at its upper portion 3b, a dispenser opening 3a from which the wipes 1 are pulled out, and a pressing member 4 that is pressed against an upper surface 2a of the stacked body 2 by biasing force. The present specification illustrates a typical form of using the wipe dispenser D in which the storage body 3 is set up with the top wipe 1 of the stacked body 2 being positioned on the top side of the wipe dispenser D (horizontal use / see FIG. 1). In this typical form of using the wipe dispenser D, the section on the top side is defined as the upper portion 3b of the storage body 3 and the upper surface 2a of the stacked body 2, and the section on the bottom side is defined as a lower portion 3c of the storage body 3 and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com