Heat protective glove

a glove and heat-resistant technology, applied in gloves, protective garments, garments, etc., can solve the problems of severe burns, cuts, lacerations, punctures, etc., and achieve the effect of reducing the risk of injury

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

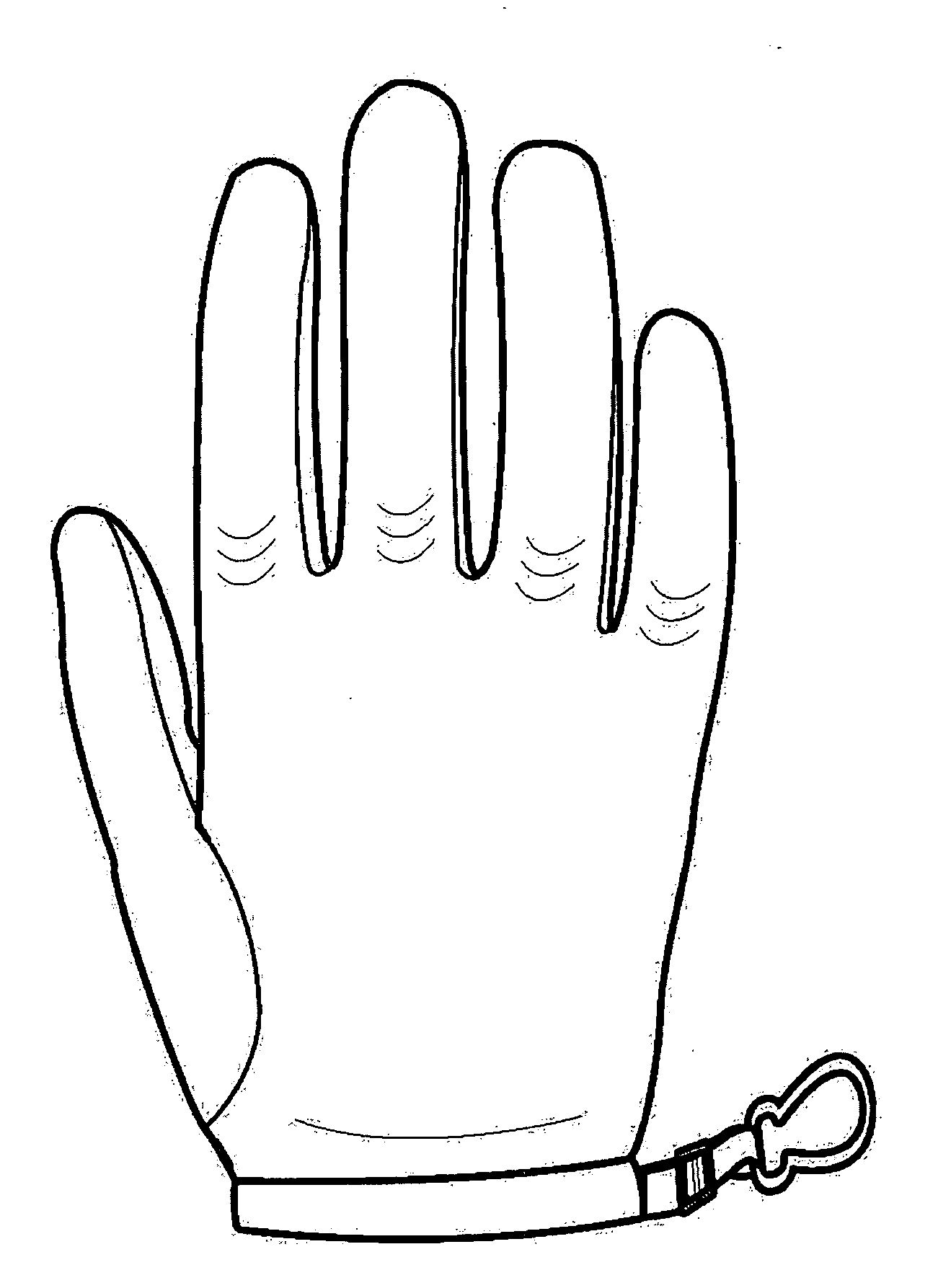

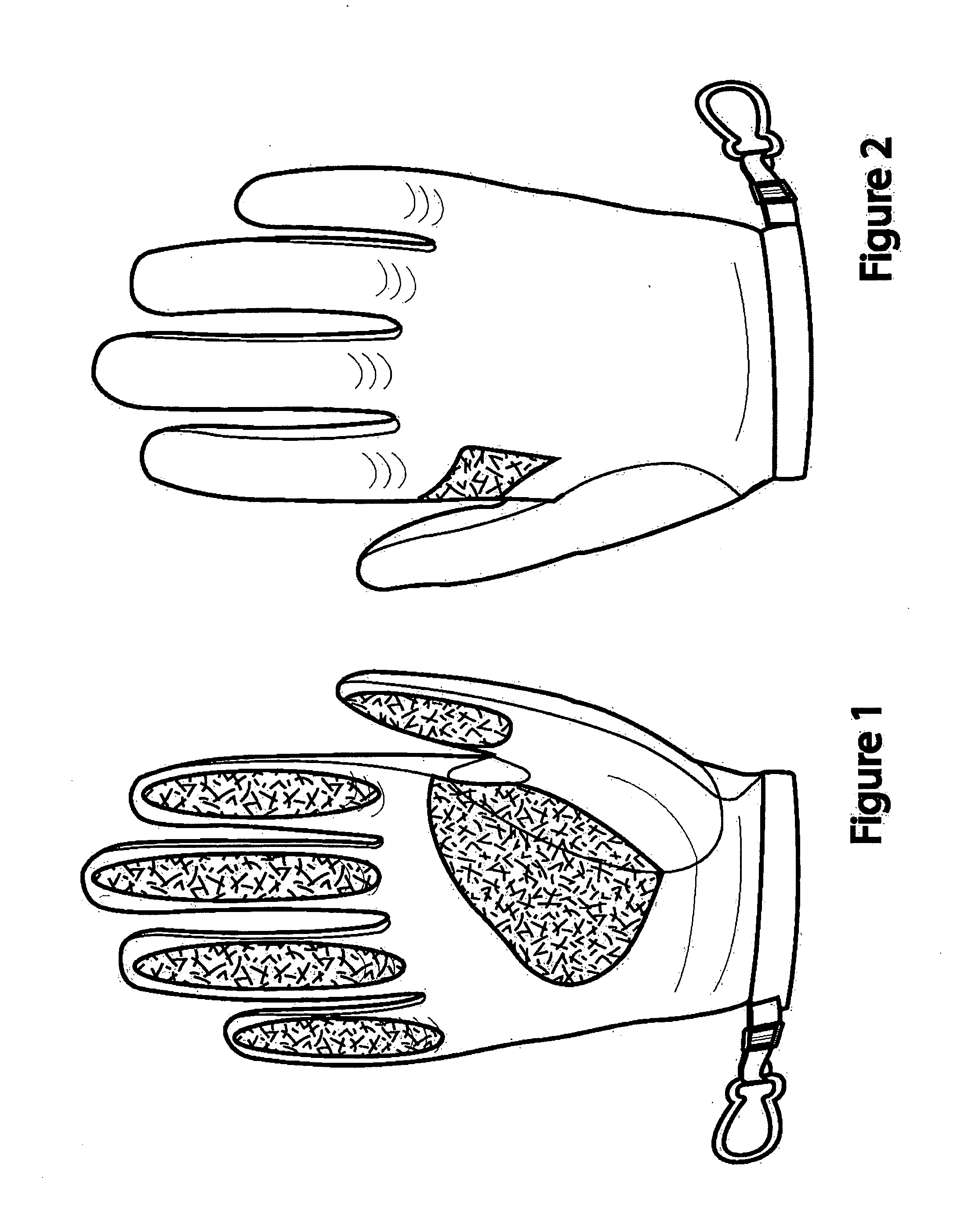

[0015]Referring first to FIG. 1, the glove (10) is depicted having the usual five fingerstalls (i.e. pinky, ring, middle, index and thumb), a thumbstall (36) and wrist cuff or wristlet (60). FIG. 1 shows the palm side of glove (10) and FIG. 2 shows the backside of glove (10).

[0016]Referring now to FIG. 2, it can be seen that glove (10) has a first shell section (55) which defines the backside (55) of glove (10). First and second shell sections (55, 56) are adjoined to one another in a suitable manner, such as by integrally sealing, sewing or stitching, thereby dividing glove (10) into the palm side half (56) and the backside half (55). The embodiment of the present invention can further comprise an attaching element (45) that is removably connected to wrist cuff (60) through fastener (50).

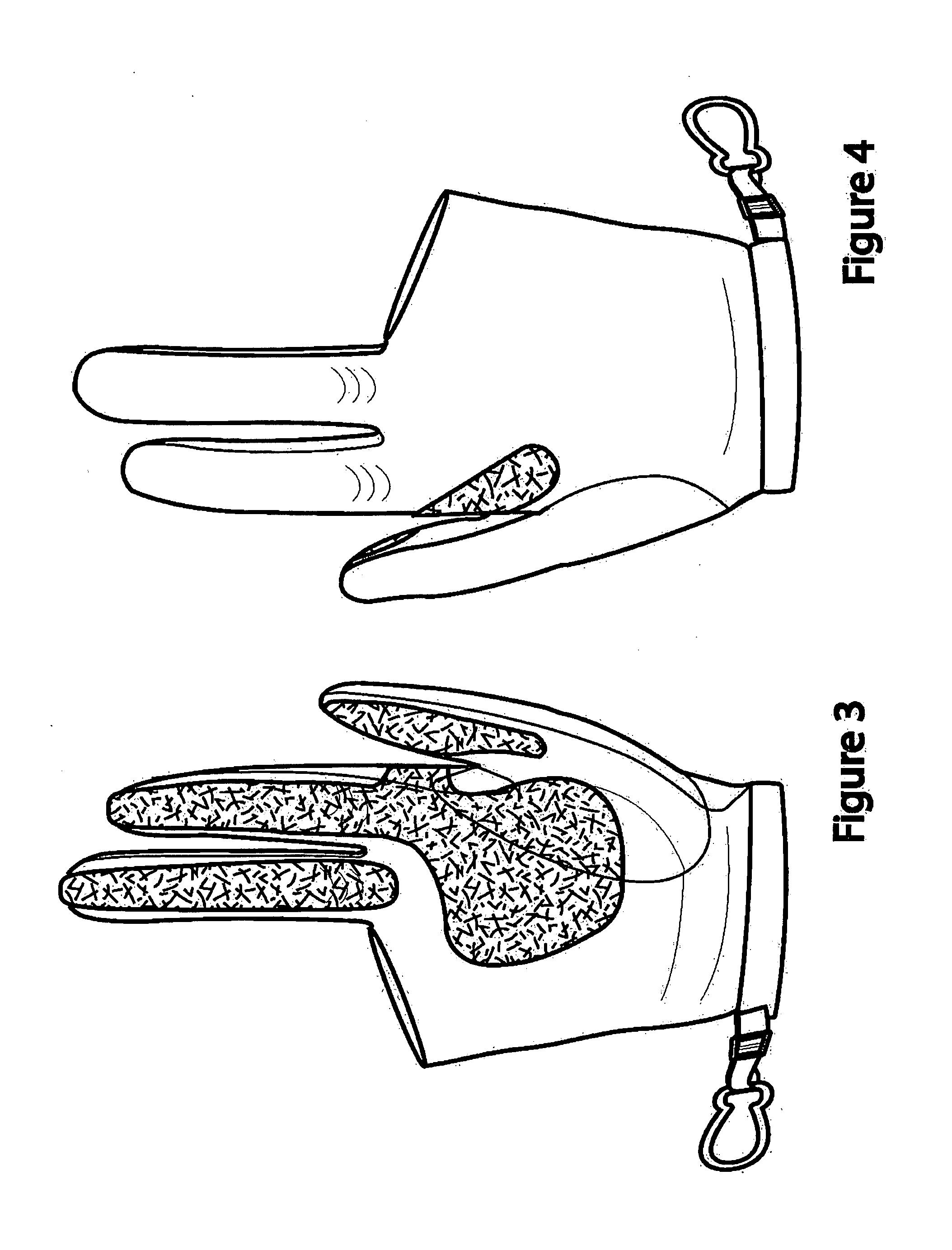

[0017]Referring to FIG. 3 there is shown an alternative embodiment showing only a three fingerstall glove (100). Referring first to FIG. 3, the glove (100) is depicted having three fingerstalls (i....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com